Galvannealed sheet steel and process for production thereof

A technology of hot-dip galvanized steel sheet and manufacturing method, applied in hot-dip galvanizing process, metal material coating process, coating and other directions, can solve the problems of non-disclosure, uneven trace components, difficult countermeasures, etc., and achieve coating properties Excellent, good looking results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~13、 and comparative example 1~11

[0055] Table 1 shows the composition of the annealed very low carbon steel sheets used in the tests. After pretreatment according to the conditions shown in Table 2, in the plating bath shown in Table 3 by electroplating (bath temperature 60 ° C, current density 30A / dm 2 ) for pre-plating Ni.

[0056] Then, at 3% H 2 +N 2 In the atmosphere, heat up to 450°C at a heating rate of 50°C / sec, immediately dip in a hot-dip galvanizing bath kept at 450°C, keep for 3 seconds and then wipe to adjust the weight per unit surface area of the coating, just after wiping Alloying is carried out at the specified heating rate, temperature, and soaking time. With regard to cooling, rapid cooling was performed at 20°C / sec after slow cooling at 2°C / sec for 10 seconds. Then, temper rolling was performed at a reduction ratio of 0.5%.

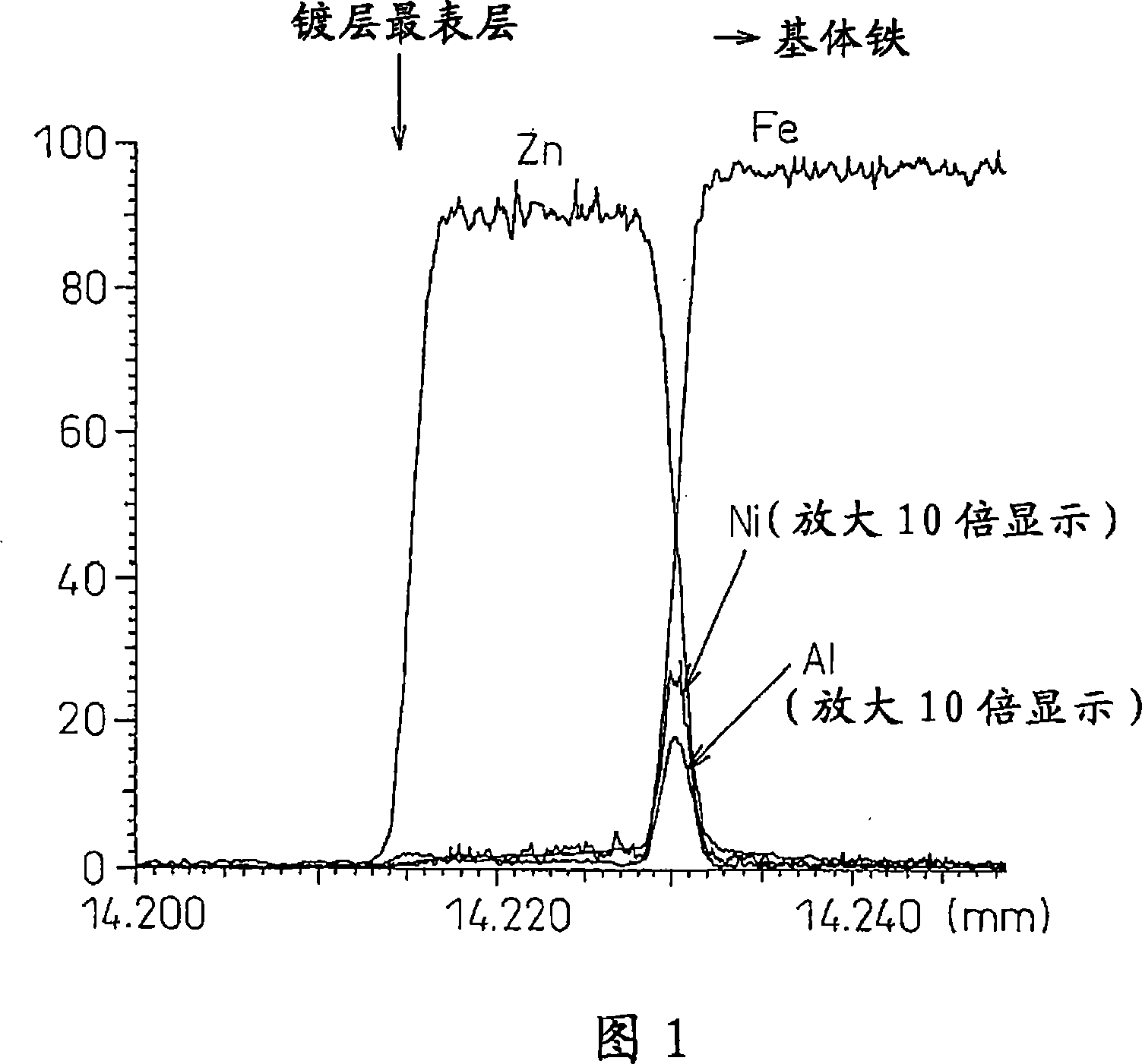

[0057] Samples were produced under various conditions (Ni pre-deposition amount, Al concentration in the plating bath, alloying conditions) shown in Table 4. ...

Embodiment 14~22 and comparative example 12、13

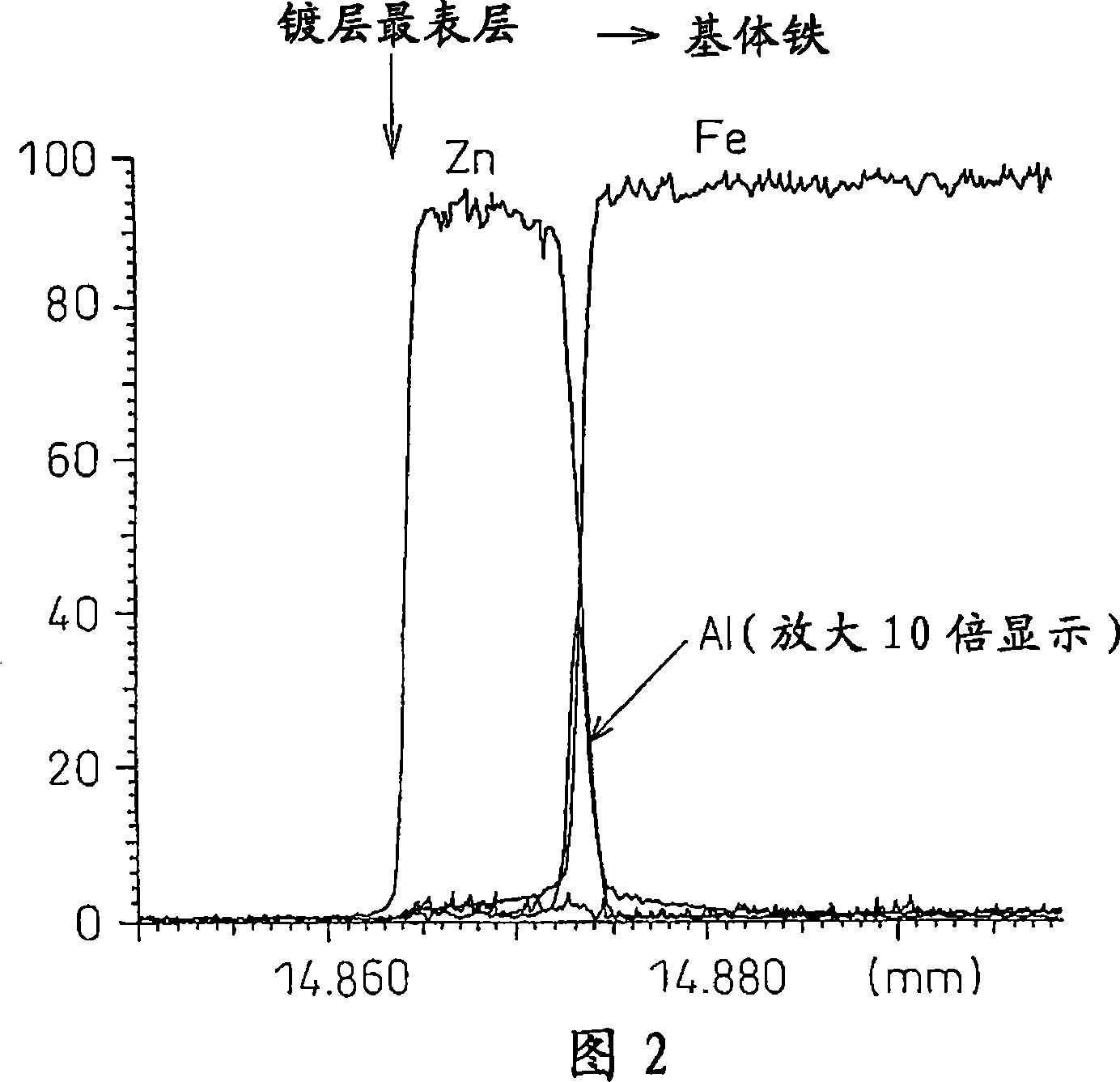

[0086] Table 7 shows the composition of the annealed very low carbon steel sheets used in the tests. After pretreatment using the conditions shown in Table 2, electroplating was carried out in the plating bath shown in Table 3 (bath temperature 60°C, current density 30A / dm 2 ) for pre-plating Ni.

[0087] Then, at 4% H 2 +N 2 Heated to 455°C at a heating rate of 50°C / sec in an atmosphere, immediately immersed in a hot-dip galvanizing bath kept at 450°C, kept for 2.5 seconds and then wiped to adjust the weight per unit surface area of the coating. Immediately after wiping, use After heating up at 50°C / sec and holding for 4 seconds, rapid cooling was performed at 50°C / sec. Thereafter, temper rolling was performed at a reduction rate of 0.5%.

Embodiment 19~25 and comparative example 15~17

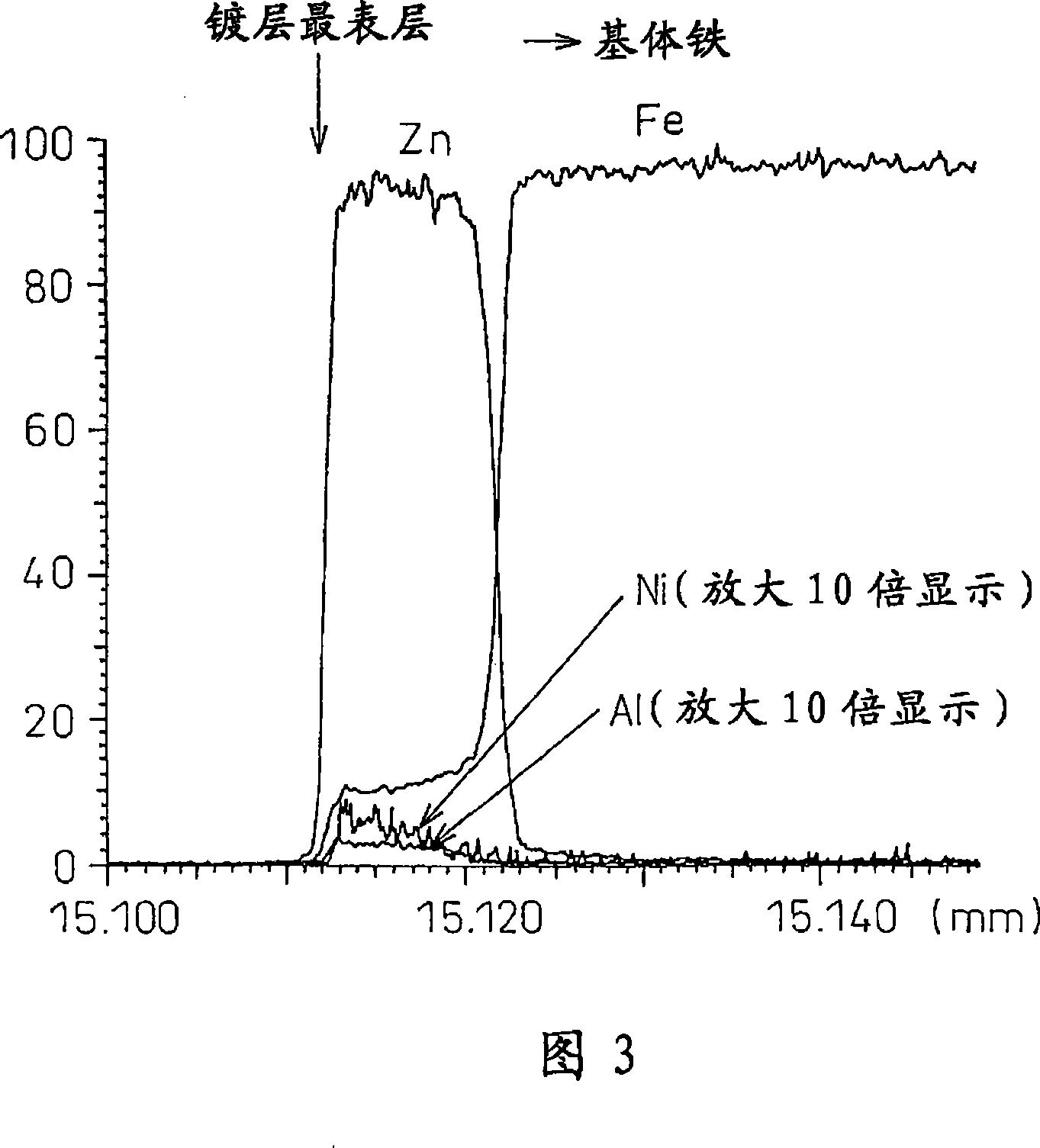

[0106] Using the cold-rolled and annealed original plate shown in Table 1, after performing the pretreatment shown in Table 2, in the plating bath shown in Table 3, electroplating (bath temperature 60 ° C, current density 30A / dm 2 ) for pre-plating Ni. Then, at 3% H 2 +N 2 In the atmosphere, heat up to 460°C at a heating rate of 50°C / s, immediately dip in a hot-dip galvanizing bath kept at 455°C, keep for 3 seconds and then wipe to adjust the weight per unit surface area of the coating. The weight per unit surface area of the coating is 60g / m 2 . Then heat alloying treatment is performed under predetermined conditions. Cooling after heating was performed at 2°C / s for 10 seconds, followed by rapid cooling at 20°C / s. Then, temper rolling was performed at a reduction ratio of 0.5%. In addition, the samples used for observing the interface alloy layer were dipped in a hot-dip galvanizing bath, held for 3 seconds, and then rapidly cooled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com