Base film for MLCC ceramic green sheet carrier, method for producing same, and carrier film

A technology for ceramic green sheets and carriers, which is applied in the field of film manufacturing, can solve the problems of uneven casting of ceramic green sheet slurry, affecting the adhesion and coating properties of the release coating, and achieves the effect of excellent coating properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

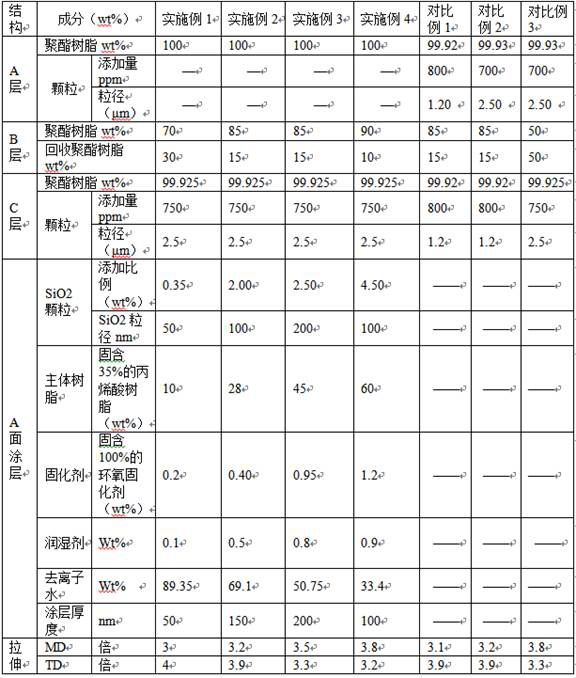

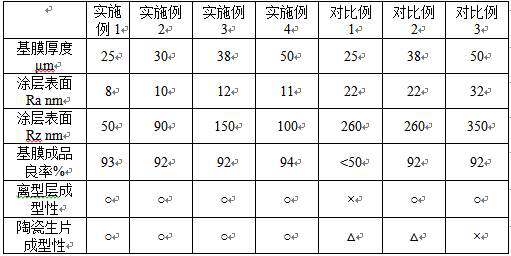

[0037] The following is a description of the preferred embodiments of the present invention, and a further description of the technical solution of the present invention, but the following embodiments are only preferred embodiments of the present invention and do not limit the present invention.

[0038] A base film for a MLCC ceramic green sheet carrier provided by the invention comprises:

[0039] Layer A: The composition is polyester resin, and its outer surface is a release surface;

[0040] Layer B: Located on the inner side of Layer A, the composition is polyester resin;

[0041] Layer C: Located inside the layer B, the composition is polyester resin and 500-3000ppm particles with a particle size of 1-4μm;

[0042] Coating: formed on the release surface of layer A, the composition of the coating includes main resin, curing agent, SiO 2 Aqueous dispersion of granules and wetting agents.

[0043] The compositions of each layer of each embodiment and comparative example ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com