High-transparency mildew-proof silane modified polymer sealant and preparation method and application thereof

A silane-modified polyether and silane-modified technology, used in the field of sealants, can solve the problems of low transparency, poor durability, yellowing, etc., and achieve a simple preparation process, improved storage stability, and strong adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

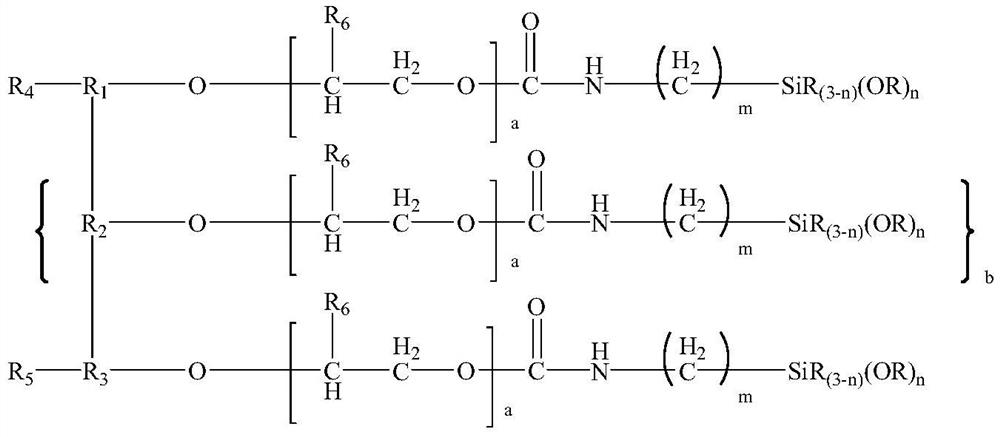

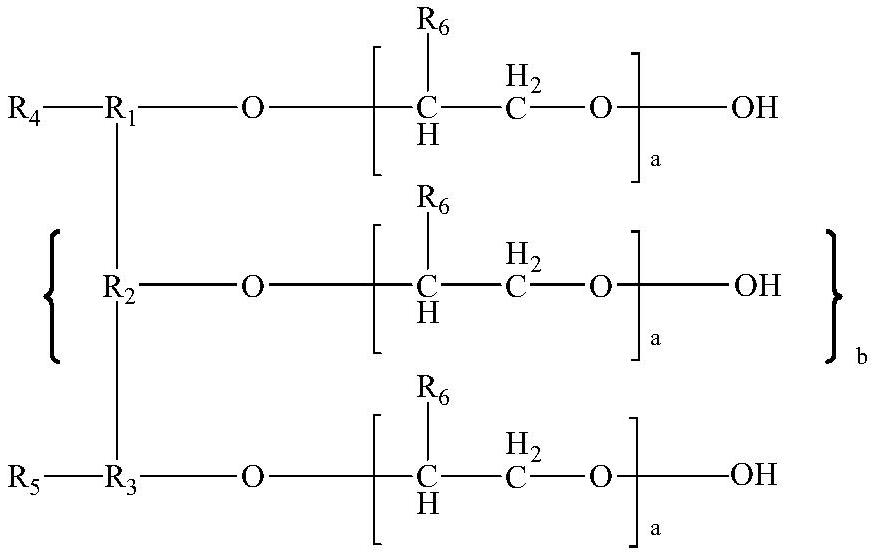

Method used

Image

Examples

Embodiment 1

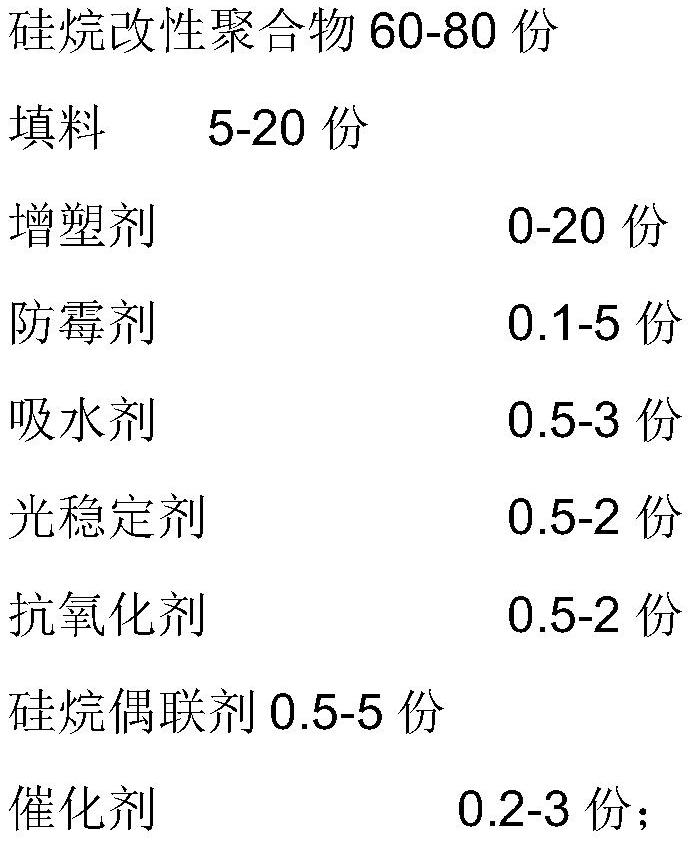

[0037] A highly transparent anti-mildew type silane-modified polymer sealant, prepared according to the following raw materials in parts by weight:

[0038]

[0039](1) According to the metering ratio of each component, 68.15 parts of polyfunctional polyether (average hydroxyl value is about 5 mgKOH / g), 20 parts of PPG-18000 (polypropylene glycol 18000), 0.5 parts of 2-methyl-4 - Isothiazolin-3-one, 1.0 part of 2-benzisothiazolin-3-one, 0.4 part of Tinuvin 326, 0.3 part of Tinuvin 770 and 0.8 part of Irgafos 1010 were vacuum treated at 80-120°C for 1-3 hours, then Cool down to 60-80°C, add 1.5 parts of isocyanate propyl trimethoxysilane, 0.3 parts of isocyanate propyl triethoxysilane and 0.05 parts of dibutyltin dilaurate, and react for 3-6 hours;

[0040] (2) Transfer the material in step (1) to a high-speed disperser, then add 5.0 parts of fumed silica, and disperse at 60-80°C for 1-2 hours in a vacuum at high speed;

[0041] (3) Finally, cool down to below 30°C, add 1.8...

Embodiment 2

[0043] A highly transparent anti-mildew type silane-modified polymer sealant, prepared according to the following raw materials in parts by weight:

[0044]

[0045]

[0046] (1) According to the metering ratio of each component, first mix 78.52 parts of polyfunctional polyether (average hydroxyl value of about 4.5mgKOH / g), 10 parts of diisononyl phthalate, 0.6 parts of 2-methyl- 1,2-benzisothiazol-3-one, 0.8 part of 3-hydroxyisothiazole, 0.8 part of Tinuvin329, 0.4 part of Tinuvin B75, 0.5 part of Irgafos 1076 and 0.3 part of Irgafos 245, vacuum treatment at 80~120℃ for 1~3h , then lower the temperature to 60-80°C, add 1.4 parts of isocyanate propyltrimethoxysilane and 0.08 parts of zinc isooctanoate, and react for 3-6 hours;

[0047] (2) Transfer the material in step (1) into a high-speed disperser, then add 8 parts of fumed silica, and disperse at 60-80°C for 1-2 hours in a high-speed vacuum;

[0048] (3) Finally lower the temperature to below 30°C, add 1.5 parts of ...

Embodiment 3

[0050] A highly transparent anti-mildew type silane-modified polymer sealant, prepared according to the following raw materials in parts by weight:

[0051]

[0052] (1) According to the metering ratio of each component, 63.93 parts of polyfunctional polyether (average hydroxyl value is about 3.5mgKOH / g), 5 parts of PPG-16000 (polypropylene glycol-16000), 10 parts of phthalic acid Dioctyl ester, 1.2 parts of 2-methyl-4-isothiazolin-3-one, 0.6 parts of 2-methyl-1,2-benzisothiazol-3-one, 0.8 parts of Tinuvin326, 0.7 parts of Tinuvin 765, 0.7 parts of Irgafos1035 and 0.2 parts of Irgafos 168 were vacuum treated at 80-120°C for 1-3 hours, then cooled to 60-80°C, and 0.8 parts of isocyanate propyl trimethoxysilane, 0.2 parts of isocyanate propyl triethoxysilane and 0.07 parts of dibutyltin dilaurate, react for 3-6 hours;

[0053] (2) Transfer the material in step (1) into a high-speed disperser, then add 10 parts of fumed silica, and disperse at 60-80°C for 1-2 hours in a high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com