Prefabricated modular tower

A modular and component technology, applied in towers, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of high cost, weak strengthening effect, affecting visual effects, etc., and achieve economical manufacturing, easy transportation, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

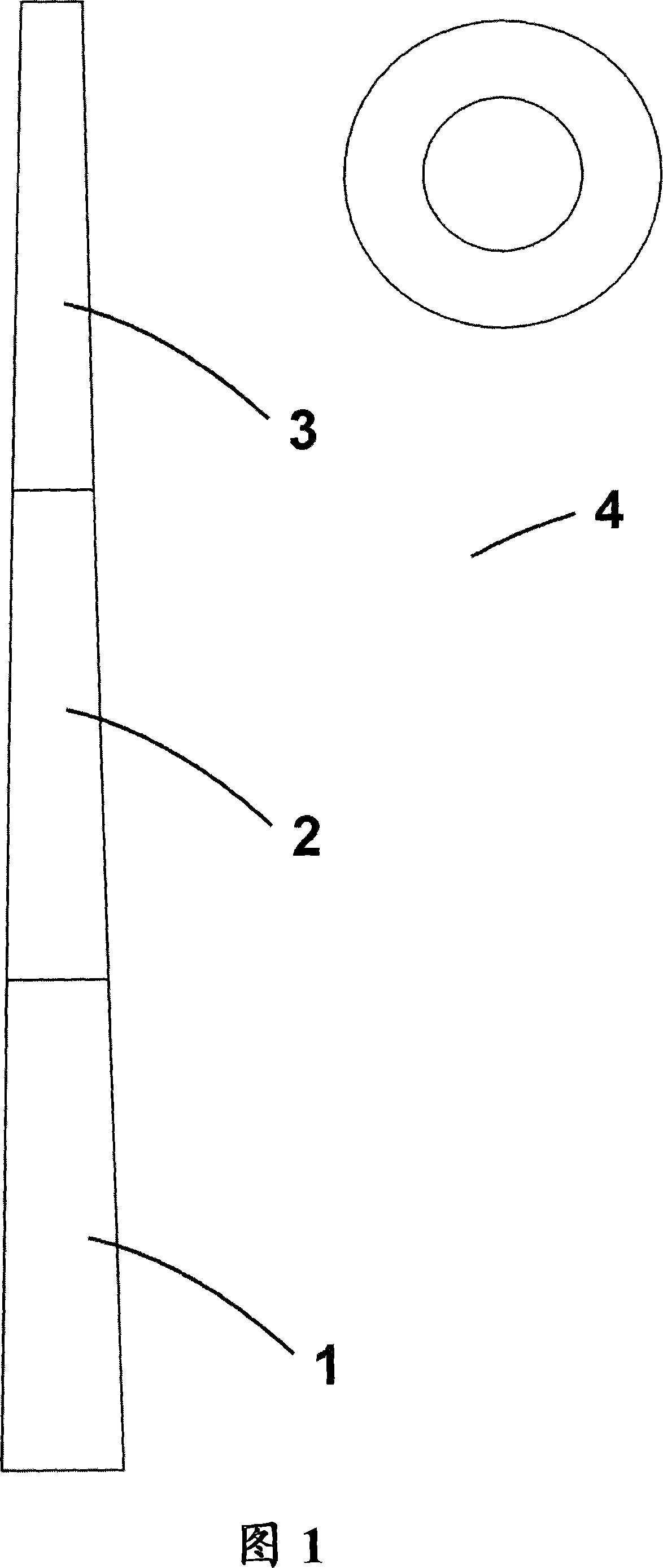

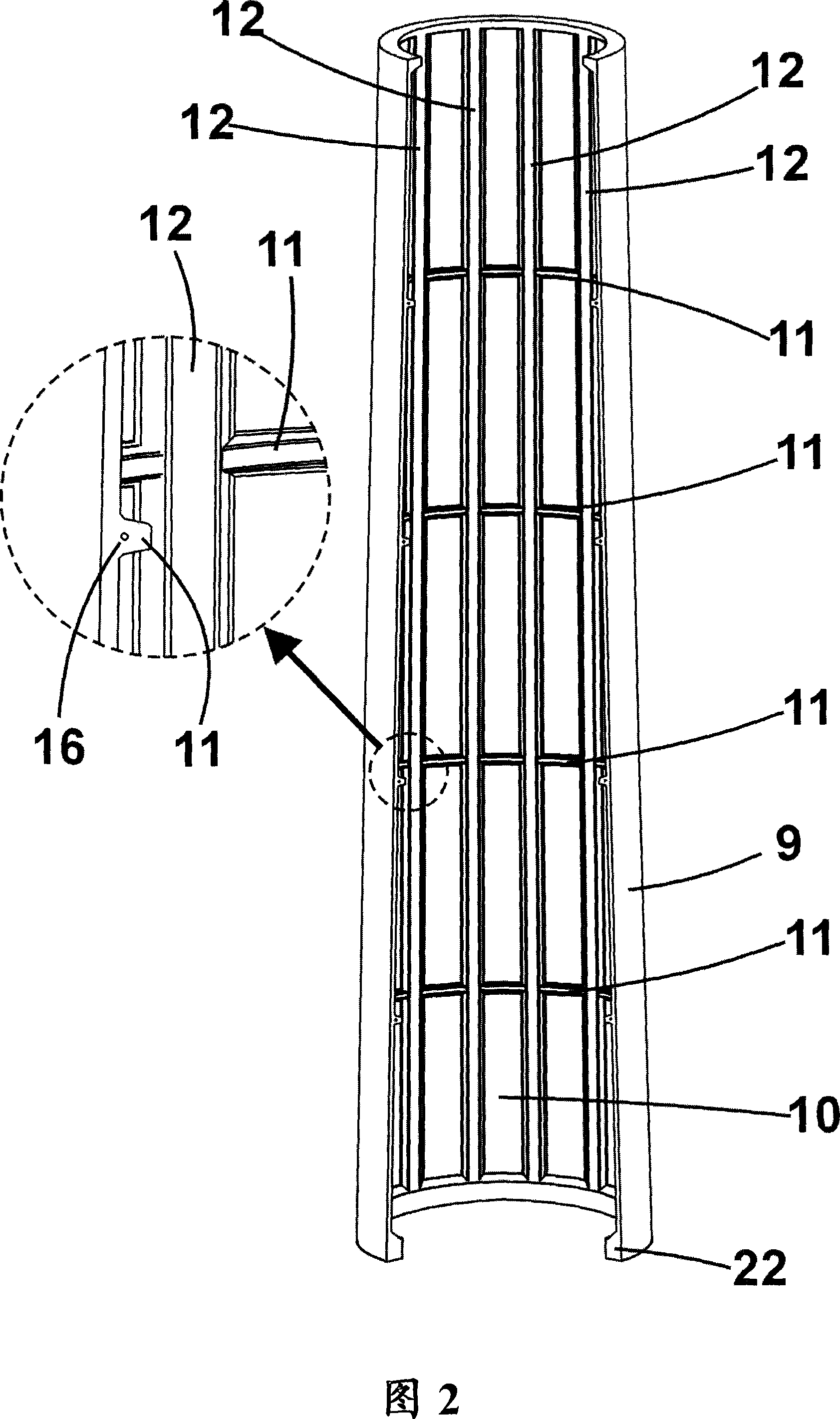

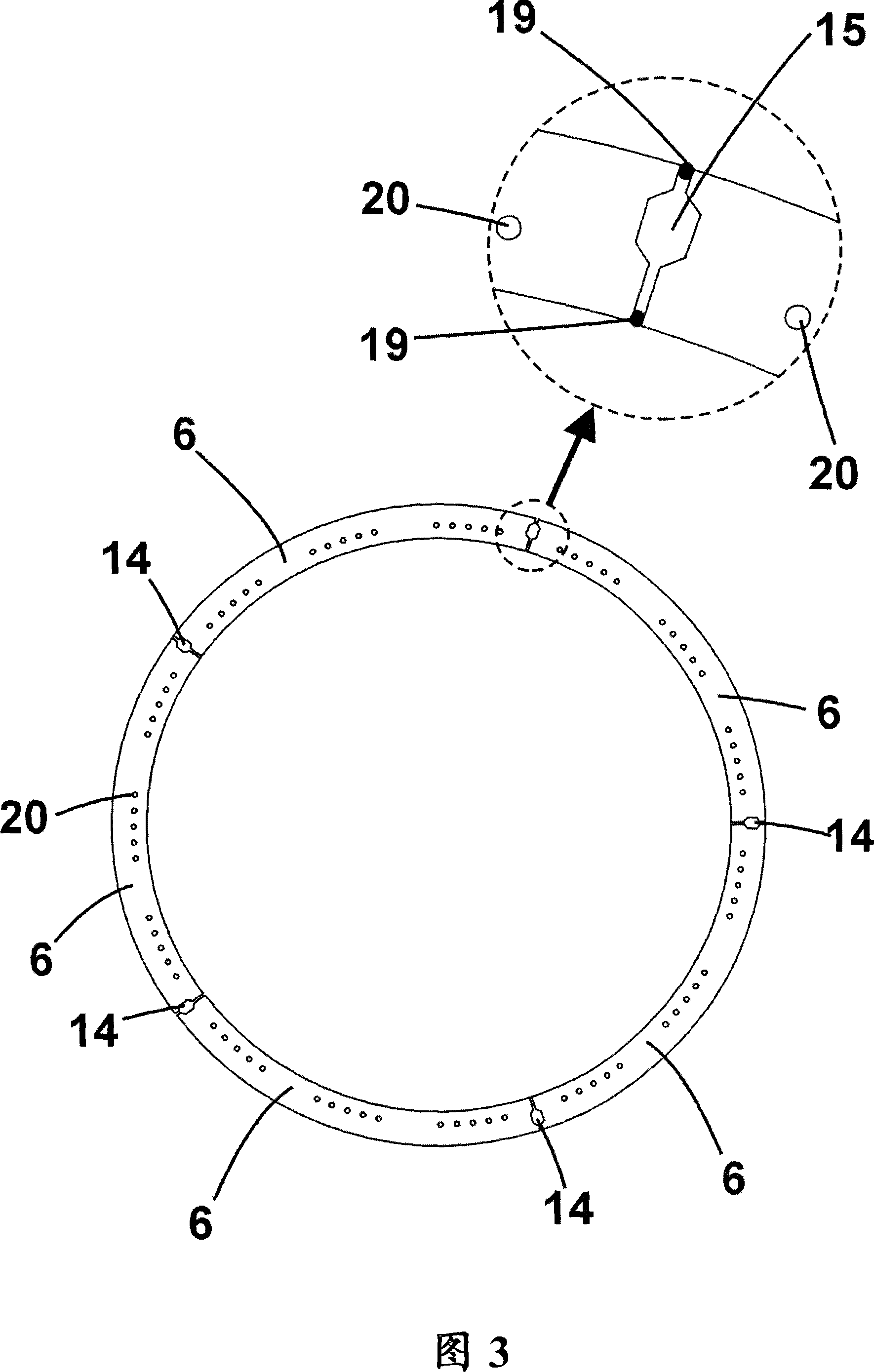

[0040] As shown in the accompanying drawings, a prefabricated modular tower 4 is the subject of the invention and basically comprises a small number of conical sections 1, 2, 3, each of which passes in turn through a small number of preferably reinforced concrete The produced identical prefabricated modular elements 6, 7, 8 are laterally joined together. In an example of a preferred embodiment, the tower 4 is divided into three conical sections 1 , 2, 3 each having a height of about 30 to 35 m, so that the total tower height is about 100 m. In this example of preferred embodiment, the lower part 1 is formed by five identical prefabricated modular elements 6 placed next to each other; the middle part 2 is formed by a further five identical prefabricated modular elements 7 also placed next to each other, but with Smaller than the diameter of the aforementioned prefabricated modular elements 6 ; the upper part 3 is formed by only three prefabricated modular elements 8 identical t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com