Dielectric adjustable low-temperature co-fired composite microwave ceramic material and preparation method thereof

A technology of low-temperature sintered ceramics and microwave ceramics, which is applied in the direction of ceramics and inorganic insulators, can solve the problems of no dielectric adjustable characteristics and low dielectric constant, achieve high dielectric adjustable characteristics, low sintering temperature, and broaden applications range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

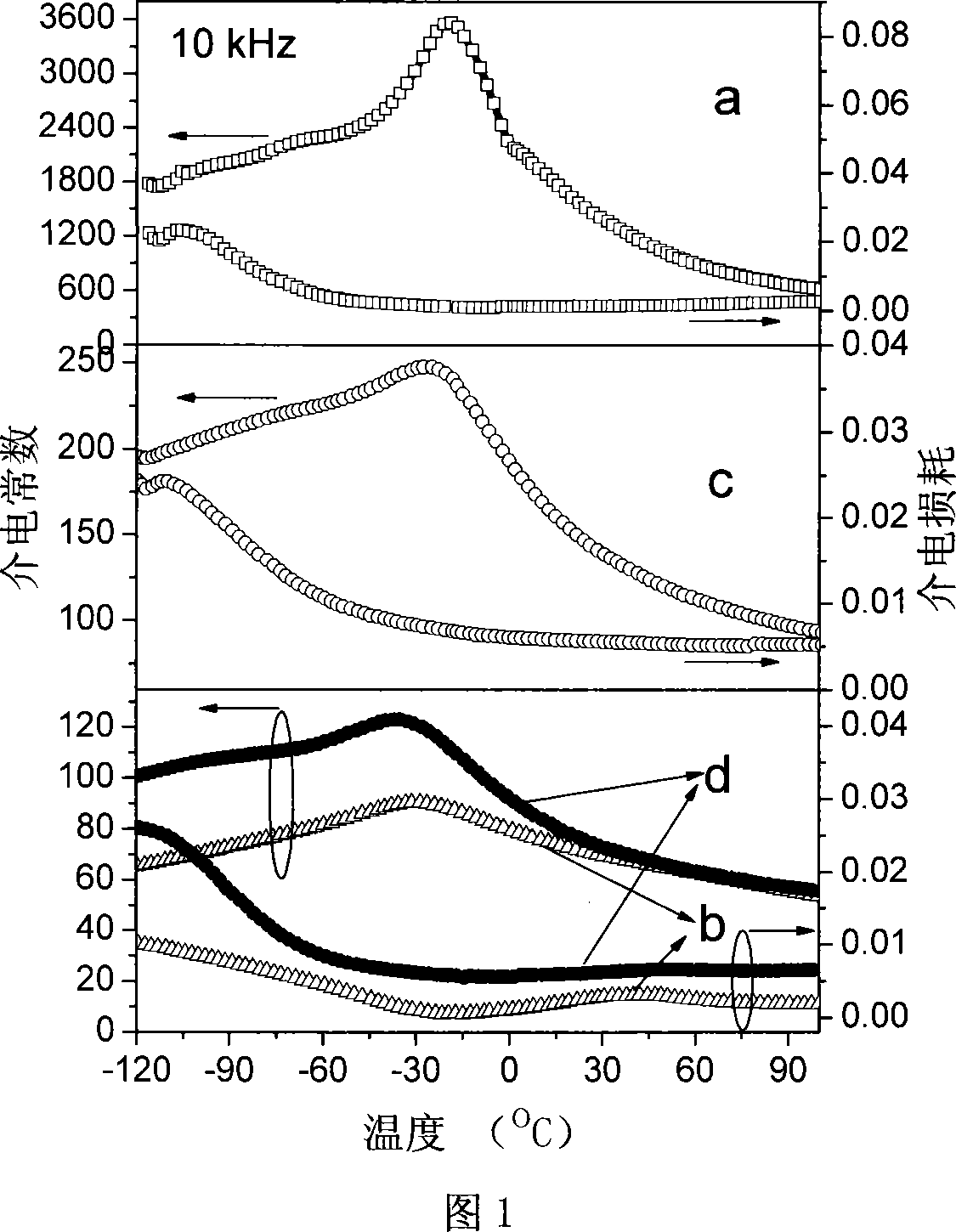

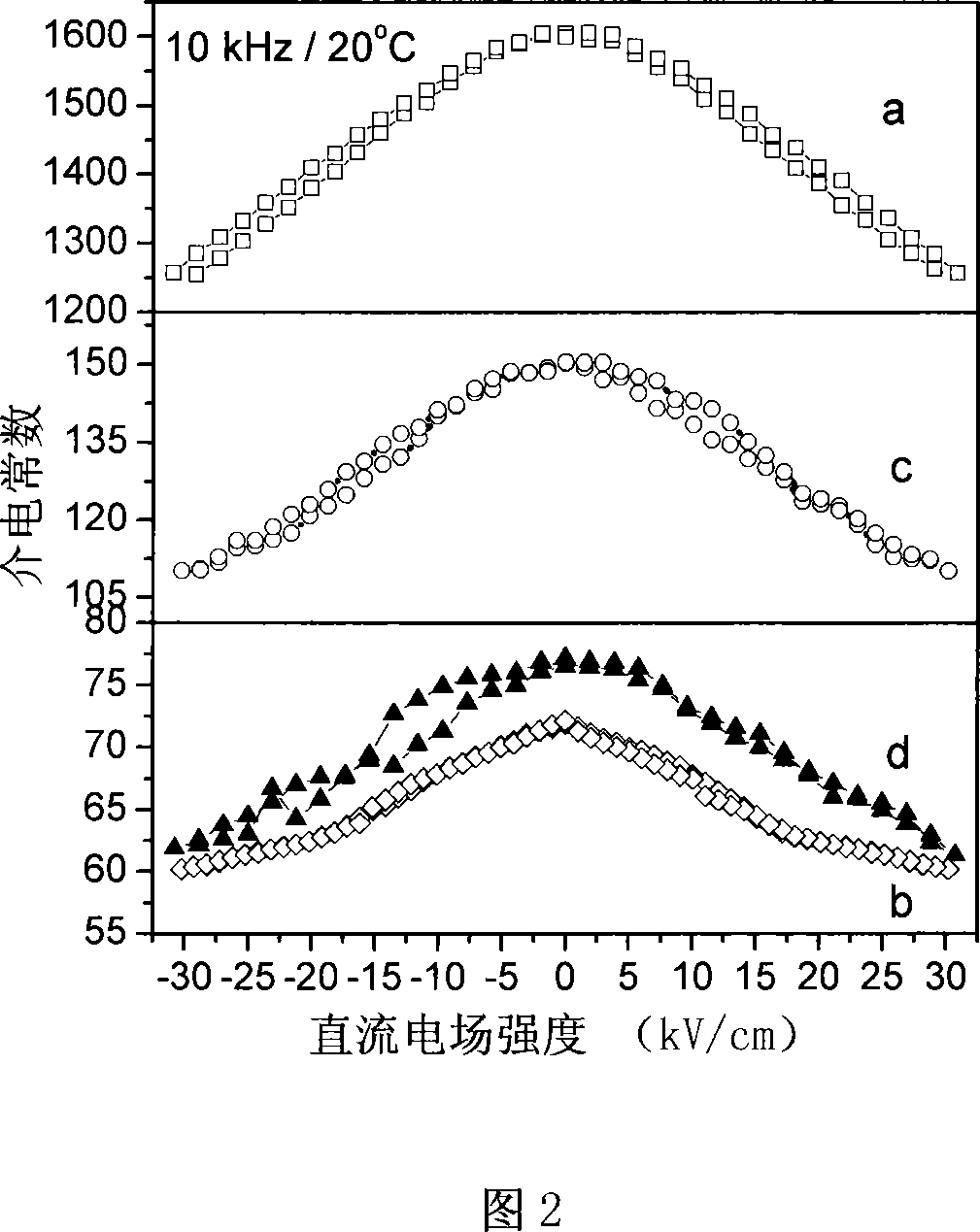

Image

Examples

preparation example Construction

[0028] xB provided by the present invention 2 o 3 ·yLi 2 O glass doped with Ba 1-x Sr x TiO 3 -M 2 TiO 4 (M=Mg, Zn) the preparation method of low-temperature co-fired composite microwave ceramics specifically comprises the following steps:

[0029] (1) Using the traditional electronic ceramic powder preparation process, through the solid-state reaction method, select BaTiO 3 and SrTiO 3 (99.9%, 100nm, provided by Shandong Guoteng Functional Ceramic Material Co., Ltd.) as the main raw material, according to a certain Ba / Sr molar ratio ingredients, the prepared raw materials are placed in a nylon ball mill jar, and zirconia balls and absolute ethanol or Ball mill with deionized water for 24 hours, dry the discharged material and pre-calcine at 1100°C for 4 hours, and get Ba (1-x) Sr x TiO 3 (x=0.3~0.6) powder for later use.

[0030] (2) According to xB 2 o 3 ·yLi 2 The B / Li molar ratio relationship of O glass, respectively weigh the HBO of the corresponding B / Li m...

Embodiment 1

[0036] Example 1 Ba 1-x Sr x TiO 3 preparation of

[0037] First, according to Ba 1-x Sr x TiO 3 The stoichiometric ratio, weigh the corresponding weight of BaTiO 3 and SrTiO 3 Put the powder in different nylon ball milling tanks, add zirconia balls and absolute ethanol, mill for 24 hours, and pre-calcine at 1100°C for 4 hours after discharging, and get Ba 1-x Sr x TiO 3 , BaTiO involved in the reaction 3 and SrTiO 3 The weight (g) of and corresponding reaction product obtained are listed in table 1:

[0038] Table 1

[0039] product

Embodiment 2

[0040] Example 2xB 2 o 3 ·yLi 2 Preparation of O glass powder

[0041] According to xB 2 o 3 ·yLi 2 The B / Li molar ratio relationship in O glass, respectively weigh the HBO with the same B / Li molar ratio relationship 3 and Li 2 CO 3 Place in an alumina crucible, slowly raise the temperature to 1000°C and keep it warm for 30 minutes, and the xB that has formed a liquid phase 2 o 3 ·yLi 2 O glass water is rapidly quenched to obtain xB 2 o 3 ·yLi 2 After the glass body is ground, pass through a 200-mesh sieve to prepare xB 2 o 3 ·yLi 2 O glass powder is ready for use, HBO participating in the reaction 3 and Li 2 CO 3 The weight (g) and the corresponding reaction product obtained are listed in Table 2: Table 2

[0042] product

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com