Micro grinding gear mill

A micro-grinding and gear technology, applied in grain processing and other directions, can solve the problems of high cost, complex structure and high energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] specific implementation plan

[0028] Embodiments of the present invention will be described below according to the accompanying drawings.

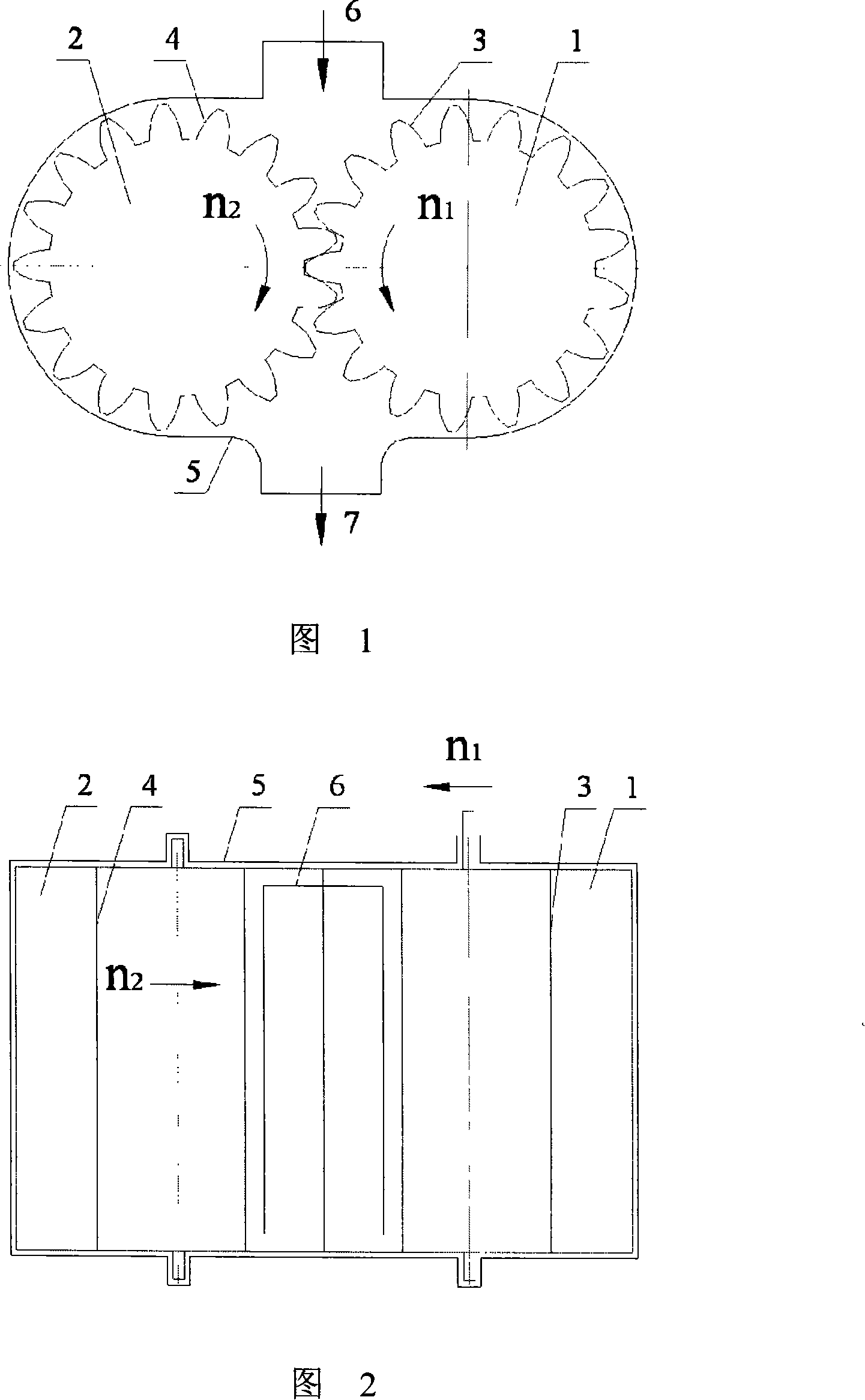

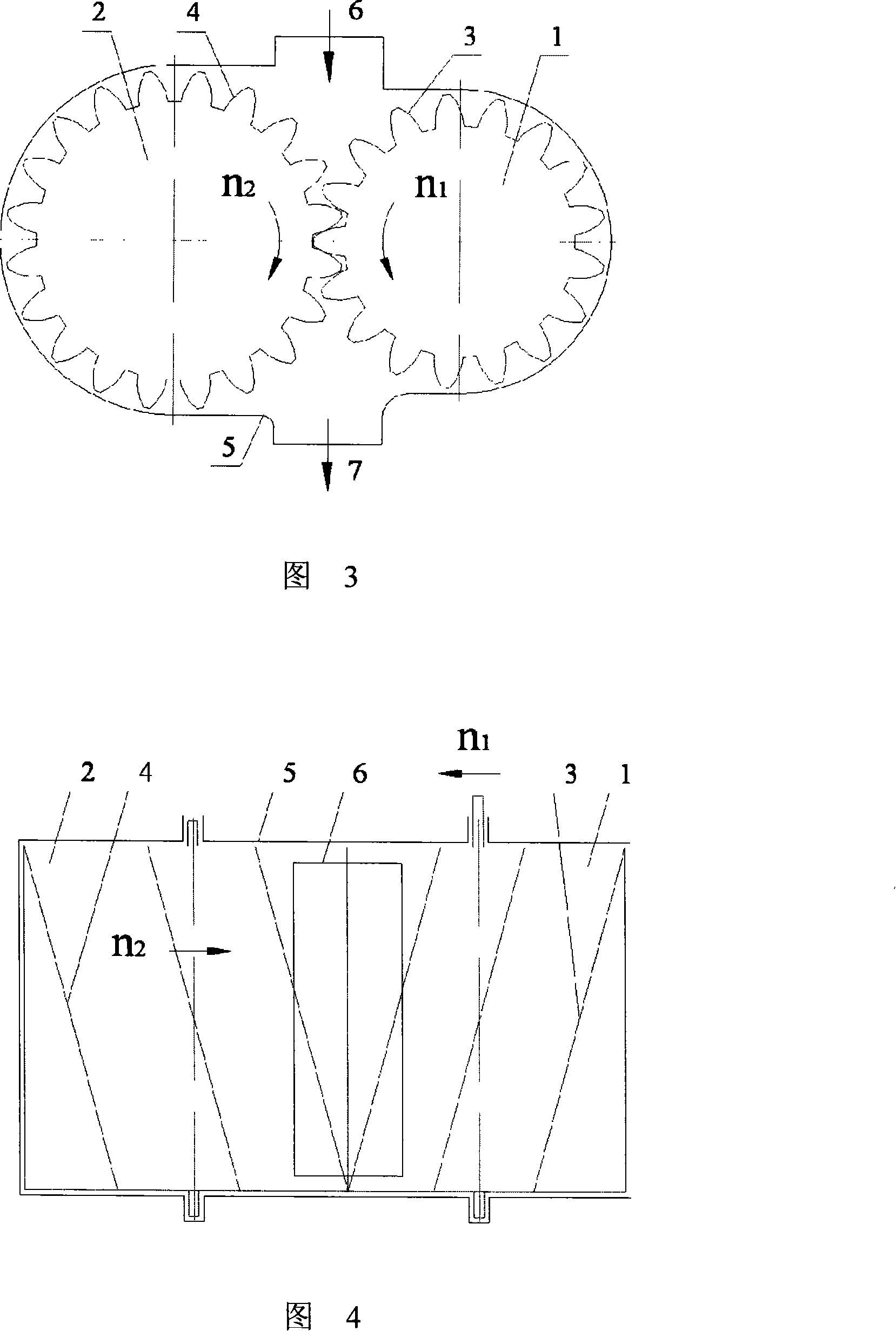

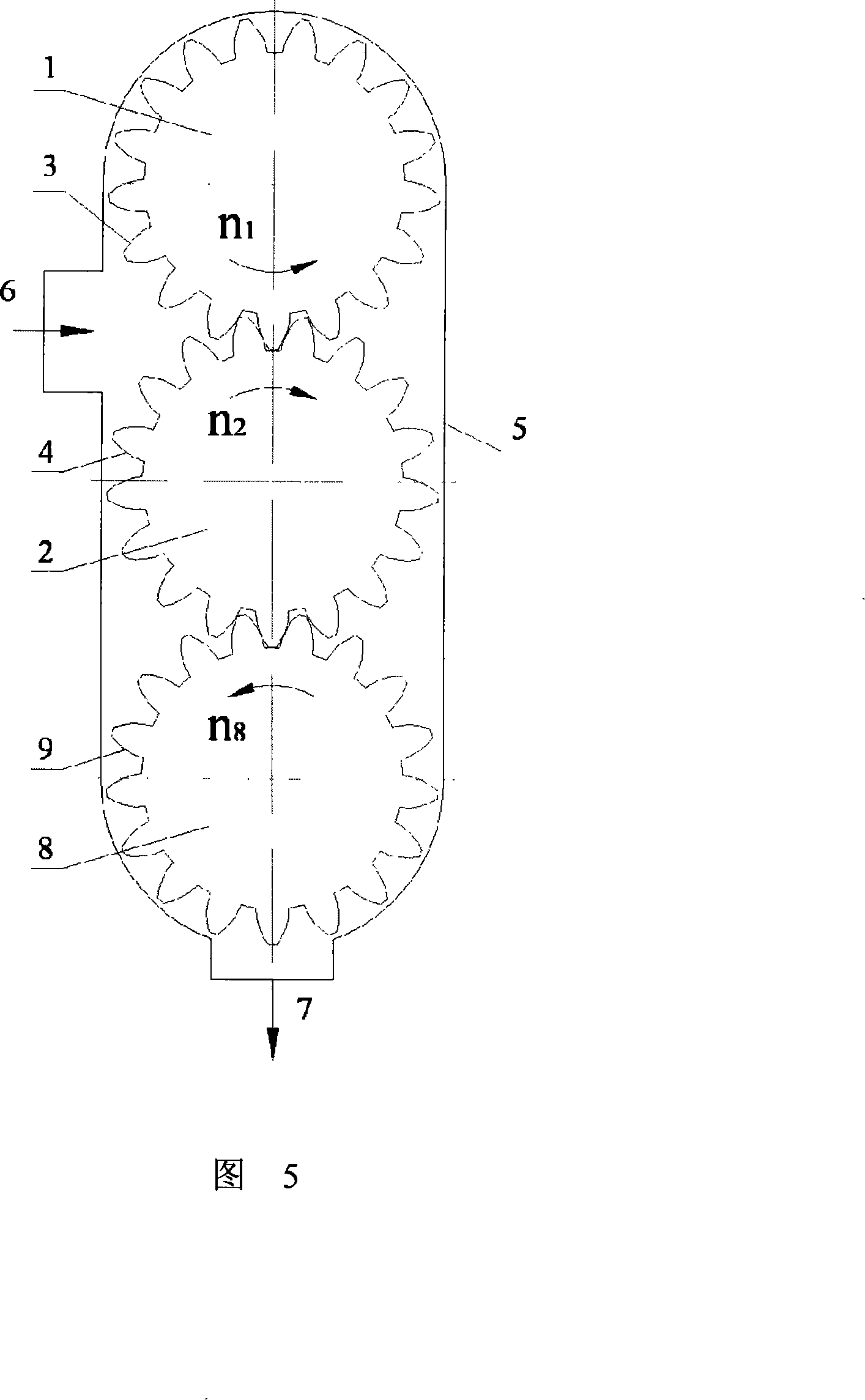

[0029] As shown in Figure 1, z 1 = The involute conjugate tooth surface 3 of 17 teeth is evenly distributed on the outer cylindrical surface of the grinding roller 1 and is connected with 1 to form a gear grinding roller, z 2 =z 1 = The involute conjugate tooth surface 4 of 17 teeth is evenly distributed on the outer cylindrical surface of the grinding roller 2 and is fixedly connected with the 2 to form another gear grinding roller. The axes of the two gear grinding rollers are parallel, and the center distance a is placed In body 5, each gear grinding roller is at constant speed ratio n 1 =-n 2 Rotate relative to the grinding body 5 around their respective axes, and the grinding body 5 is respectively provided with a feed inlet 6 and a discharge outlet 7 to form a micro-grinding gear mill; the two gear grinding rollers are st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com