High-performance rolling concrete and preparation method thereof

A RCC, high-performance technology for climate sustainability, sustainable waste treatment, solid waste management, etc. It can solve problems such as high water consumption, poor durability of RCC dams, and achieve low carbonation resistance. , high grindability, good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

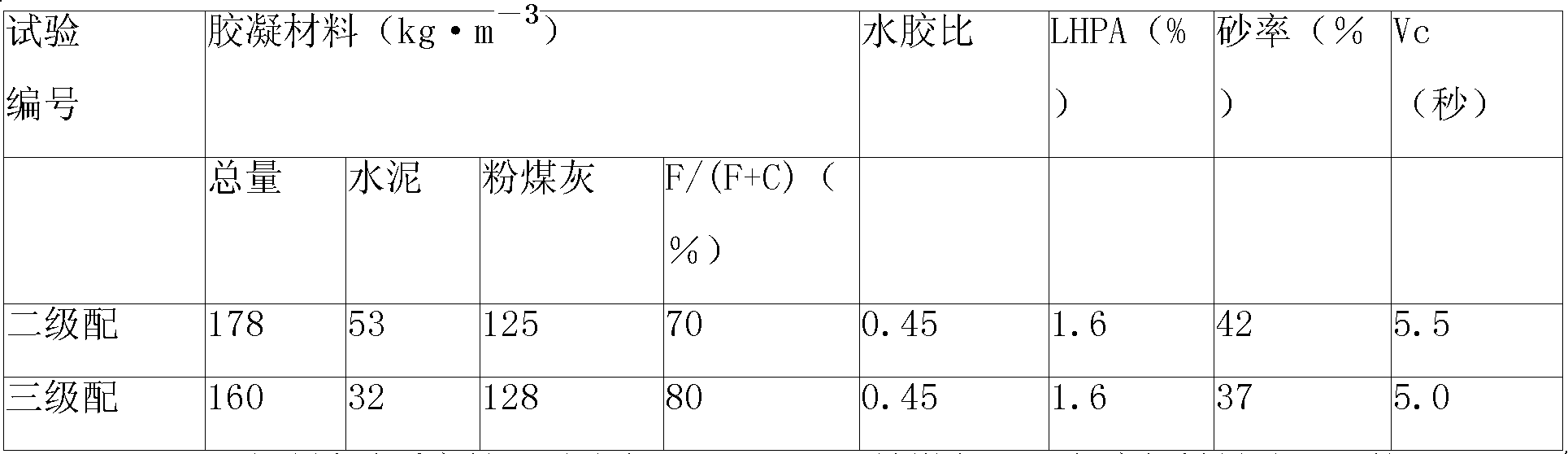

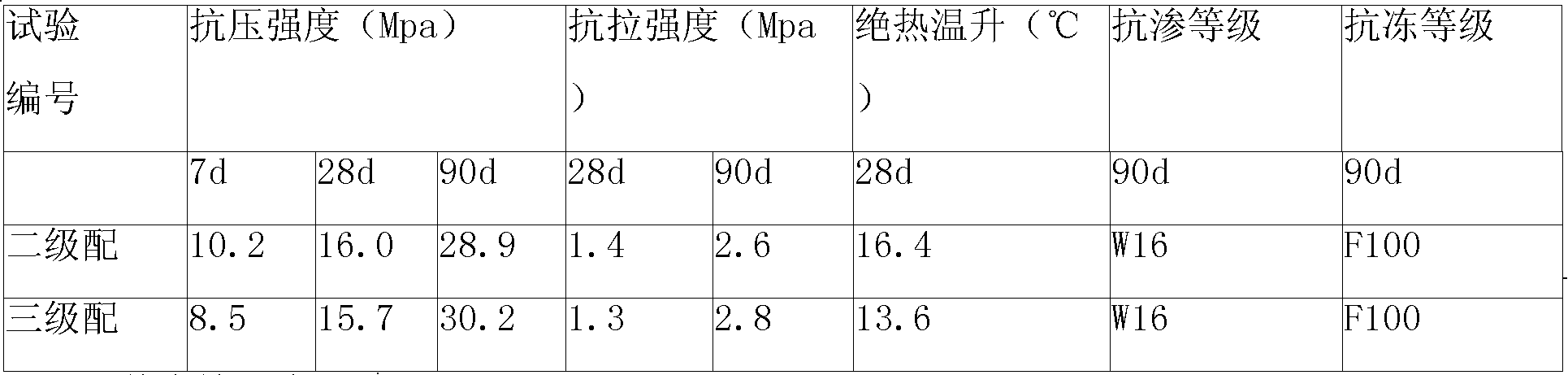

[0022] Raw materials: 32Kg of cement with a strength of not less than 42.5MPa, 128Kg of fly ash, 883Kg of natural sand or artificial sand with a fineness in the range of medium sand, 1325Kg of stones with a particle size within the range of 5-40mm, and high-performance polycarboxylate water reducing Agent 2.56Kg and water 72Kg.

[0023] Preparation method: first mix cement and national standard I grade fly ash together, then add sand, gravel, cement and national standard I grade fly ash cementitious material, polycarboxylate high-performance water reducer and water Mix in a forced concrete mixer for 100 seconds to get 1 cubic meter of high-performance roller compacted concrete.

[0024] During production, the amount of sand and stone to be added as aggregate is determined according to the amount of roller compacted concrete to be produced and the required apparent density. When aggregate is added, the apparent density of the produced roller compacted concrete is controlled. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com