Weave for natural color cotton and far infrared functional fibre core-spun yarn

A functional fiber and far-infrared technology, applied in textiles, papermaking, yarn, etc., can solve the problems affecting the overall quality of fabrics and chemical substance residues, and achieve the effect of rich yarn colors, complete varieties, and shortened process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

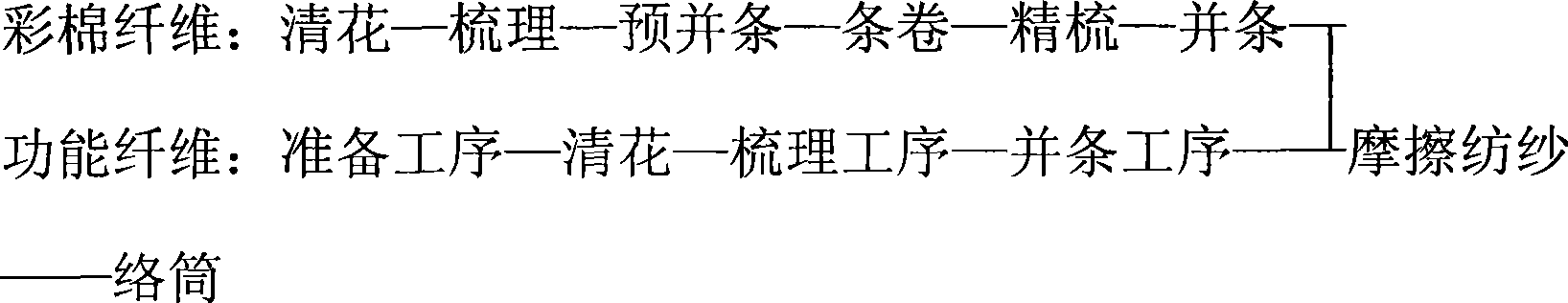

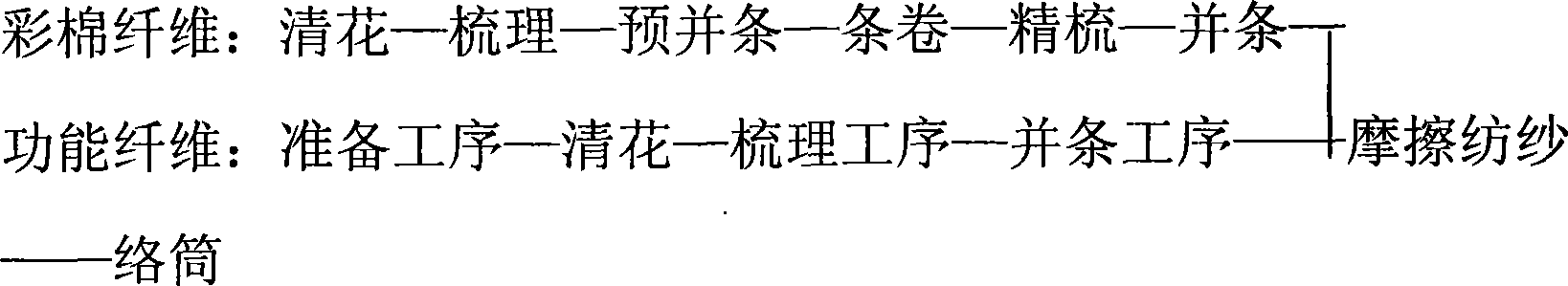

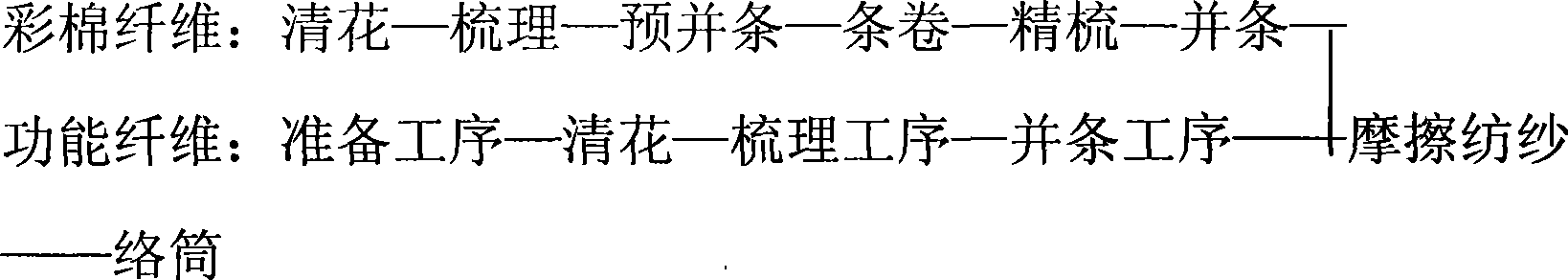

[0010] The preparation method of the present invention is the following steps:

[0011] According to the difference of the far-infrared functional fiber carrier, choose oil agent or antistatic agent, spray evenly on the fiber pile, the dosage is 5-8%, and pile up for more than one day and one night. , pay attention to the humidity in the workshop during the spinning process. The strength of colored cotton fibers is slightly weaker than that of ordinary cotton fibers. Each process should be grasped more frequently and less grasped, more loosened and less waste, and the cotton grasping will drop by about 2mm each time. The disc grasping machine is 2.8r / Min, try to catch the cotton as small as possible, the beater speed should not be too fast, the final drawing weight is 12.5-18.5, the spinning process is carried out on the friction spinning machine, and the functional fiber strips are fed into the twisting area of the dust cage after drafting to form cores Yarn, colored cotto...

Embodiment 1

[0014] Ingredients: far-infrared polyester triangular hollow fiber 65%, red natural colored cotton 35%;

[0015] Preparation:

[0016] According to the difference of the far-infrared functional fiber carrier, choose oil agent or antistatic agent, spray evenly on the fiber pile, the dosage is 5-8%, and pile up for more than one day and one night. , pay attention to the humidity in the workshop during the spinning process. The strength of colored cotton fibers is slightly weaker than that of ordinary cotton fibers. Each process should be grasped more frequently and less grasped, more loosened and less waste, and the cotton grasping will drop by about 2mm each time. The disc grasping machine is 2.8r / Min, try to catch the cotton as small as possible, the beater speed should not be too fast, the final drawing weight is 12.5-18.5, the spinning process is carried out on the friction spinning machine, and the functional fiber strips are fed into the twisting area of the dust cage a...

Embodiment 2

[0018] Ingredients: 65% of far-infrared polyester triangular hollow fiber, 35% of green natural colored cotton, and its preparation method is the same as that of Example 1.

[0019] In summary, the core-spun yarn of the present invention uses natural colored cotton and far-infrared polyester triangular hollow fiber as raw materials, has rich colors, short technological process, reduces the use of chemical reagents, and ensures the quality of the yarn while being environmentally friendly. It has good economic and social benefits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com