Calibration device for aligning system of stepper and its calibration method

A technology of an alignment system and a calibration device, which is applied to the exposure device of photoengraving process, microlithography exposure device, image data processing, etc. Installation requirements, the difficulty of achieving a higher-precision alignment system, etc., to achieve the effect of improving accuracy, easy placement, and reducing calculation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

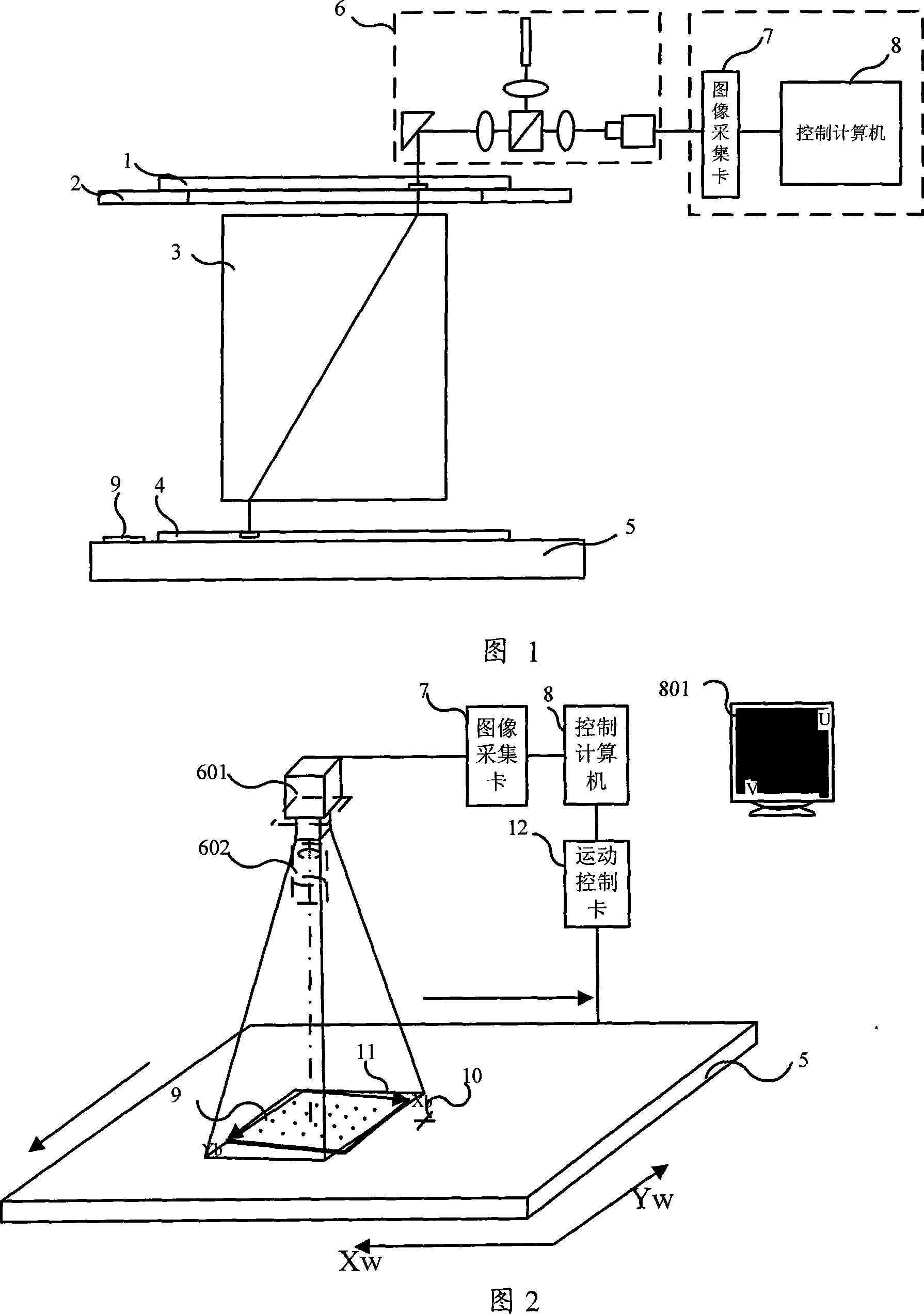

[0020] Please refer to FIG. 1 for a schematic structural diagram of a machine vision alignment system in a stepper lithography machine. The alignment system of the stepper lithography machine includes: a reticle 1 , a mask carrier 2 , a projection objective 3 , a silicon wafer 4 , a silicon wafer carrier 5 , an imaging system 6 , an image acquisition card 7 and a control computer 8 . A calibration plate 9 is installed on the silicon wafer carrier platform 5 , and images of marks on the mask plate 1 and silicon wafer 4 are obtained through the imaging system 6 , and the digital images are collected and transmitted to the control computer 8 through the image acquisition 7 . Through the pattern recognition technology, the position of the image coordinate system of the mark is respectively acquired and converted into the coordinate system of the mask carrier 2 and the coordinate system of the silicon wafer carrier 5 . Automatic alignment is achieved through the coordinate position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com