A method and device for low-temperature start of the fuel battery

A fuel cell, low temperature technology, applied in fuel cells, fuel cell additives, circuits, etc., can solve the problems of long startup time and difficult control, and achieve the effects of rapid startup, low operating cost, and good feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

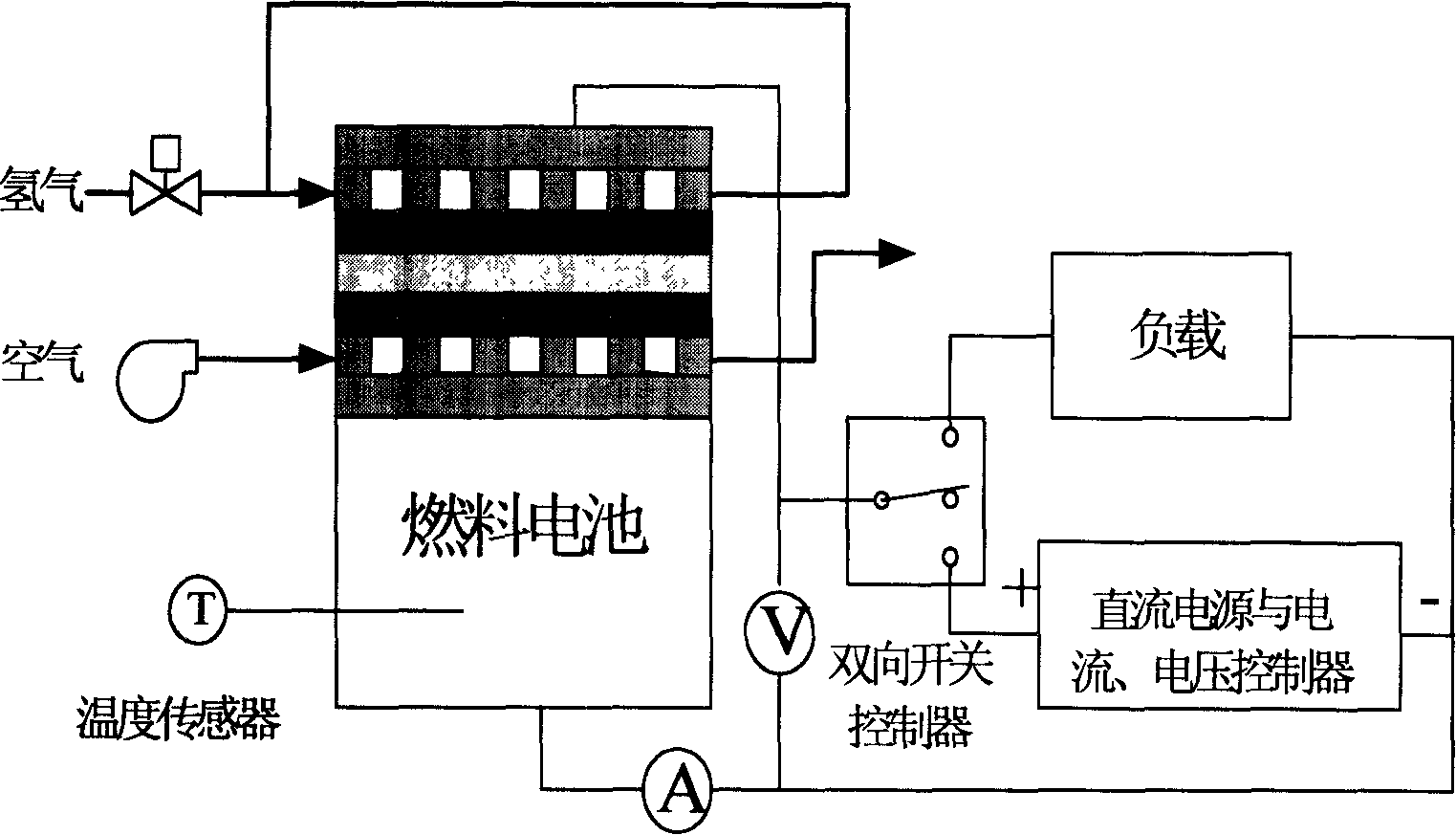

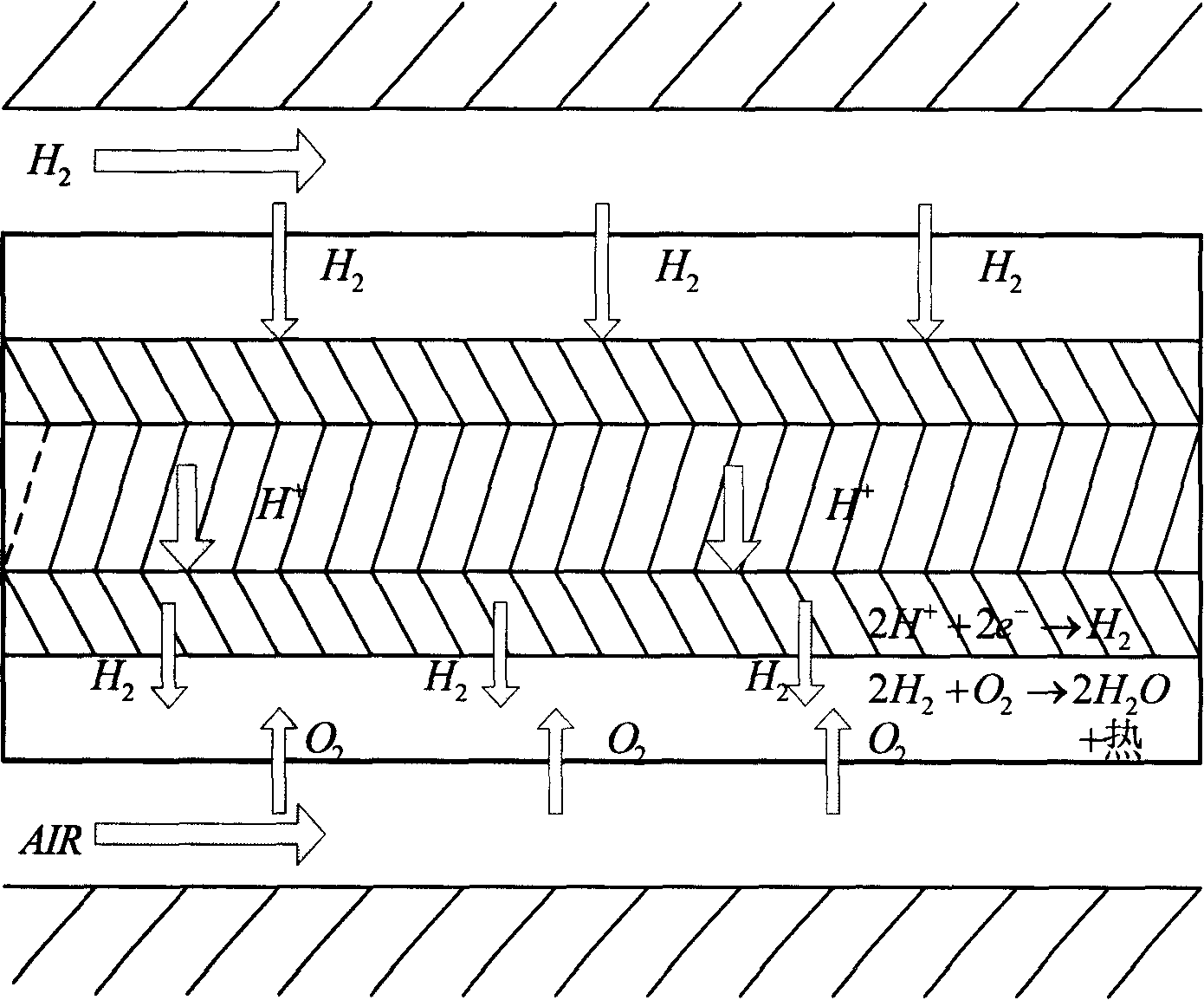

[0043] The fuel cell is composed of 5 single cells, the activation area of each cell is 128 square centimeters, and the proton exchange membrane is Nafion112. The fuel gas is pure hydrogen, and the oxygen is provided by the blower.

[0044] The fuel cell passes through N before parking 2 Gas purge.

[0045] Measure the temperature inside the battery with a platinum resistance thermometer.

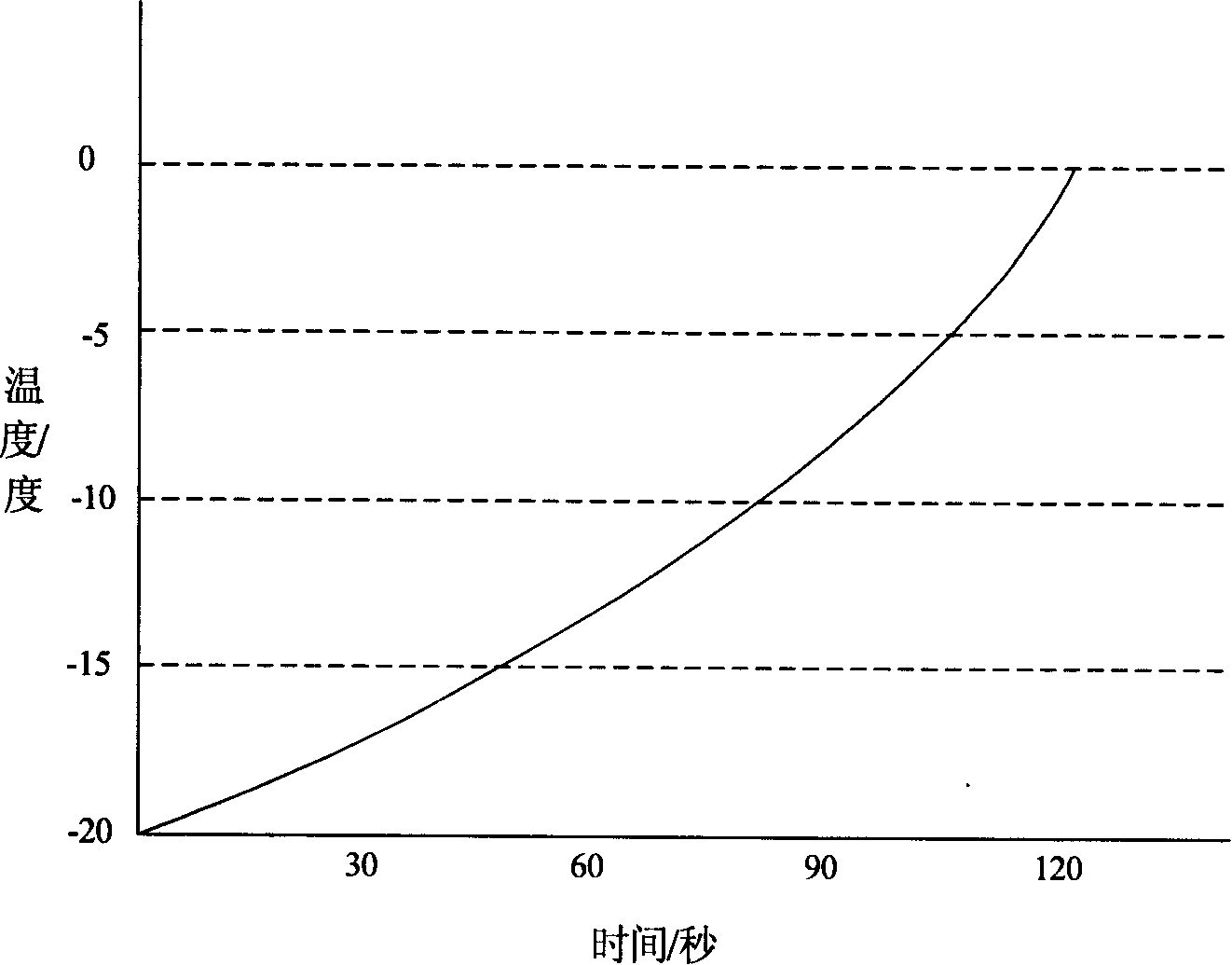

[0046] The fuel cell starts at minus 20 degrees, the hydrogen control valve is opened, and the hydrogen flow meets the current density of 500 mA per square centimeter; the bidirectional switch controller is connected to the DC power supply, and the current and voltage controllers are adjusted so that the current density passing through the battery is 500 Milliamperes per square centimeter; turn on the fan to adjust the air volume so that the oxygen meets the oxygen required by the current density of 500 milliamperes per square centimeter.

[0047] After the internal temperature of the ...

Embodiment 2

[0052] The fuel cell is 10 single cells, the activation area of the single cell is 25 square centimeters, and the proton exchange membrane is Nafion112. The fuel gas is pure hydrogen, and the oxygen is provided by the blower.

[0053] The fuel cell passes through N before parking 2 Gas purge.

[0054] The temperature sensor measures the temperature inside the battery.

[0055] Start under the environmental condition of minus 20 degrees, open the hydrogen control valve, the hydrogen flow rate meets the current density of 400 mA per square centimeter; the bidirectional switch controller connects the DC power supply, adjusts the current and voltage controllers, so that the current density passing through the battery is 400 mA per square centimeter; turn on the fan to adjust the air volume so that the oxygen meets the oxygen required by the current density of 400 mA per square centimeter.

[0056] The voltage at both ends of the battery gradually changes from negative to posi...

Embodiment 3

[0059] The fuel cell is a single cell, the activation area of the single cell is 25 square centimeters, and the proton exchange membrane is Nafion112. The fuel gas is pure hydrogen, and the oxygen is pure oxygen.

[0060] Before the fuel cell is placed in a low temperature environment, the N 2 Gas purge.

[0061] The temperature sensor measures the temperature inside the battery.

[0062] Start under the environmental conditions of minus 15 degrees, open the hydrogen control valve, and the hydrogen flow rate meets the current density of 400 mA per square centimeter; the bidirectional switch controller is connected to the DC power supply, and the current and voltage controllers are adjusted so that the current density passing through the battery is 400 milliamperes per square centimeter; oxygen meets the oxygen required for the current density of 400 milliamperes per square centimeter.

[0063] The voltage at both ends of the battery gradually changes from negative to posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com