Processes for the isomerization of paraffins of 5 and 6 carbon atoms with methylcyclopentane recovery

A technology for isomerization and paraffin, which is used in isomerization to produce hydrocarbons, chemical instruments and methods, organic chemistry, etc. to improve economic feasibility and reduce membrane surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

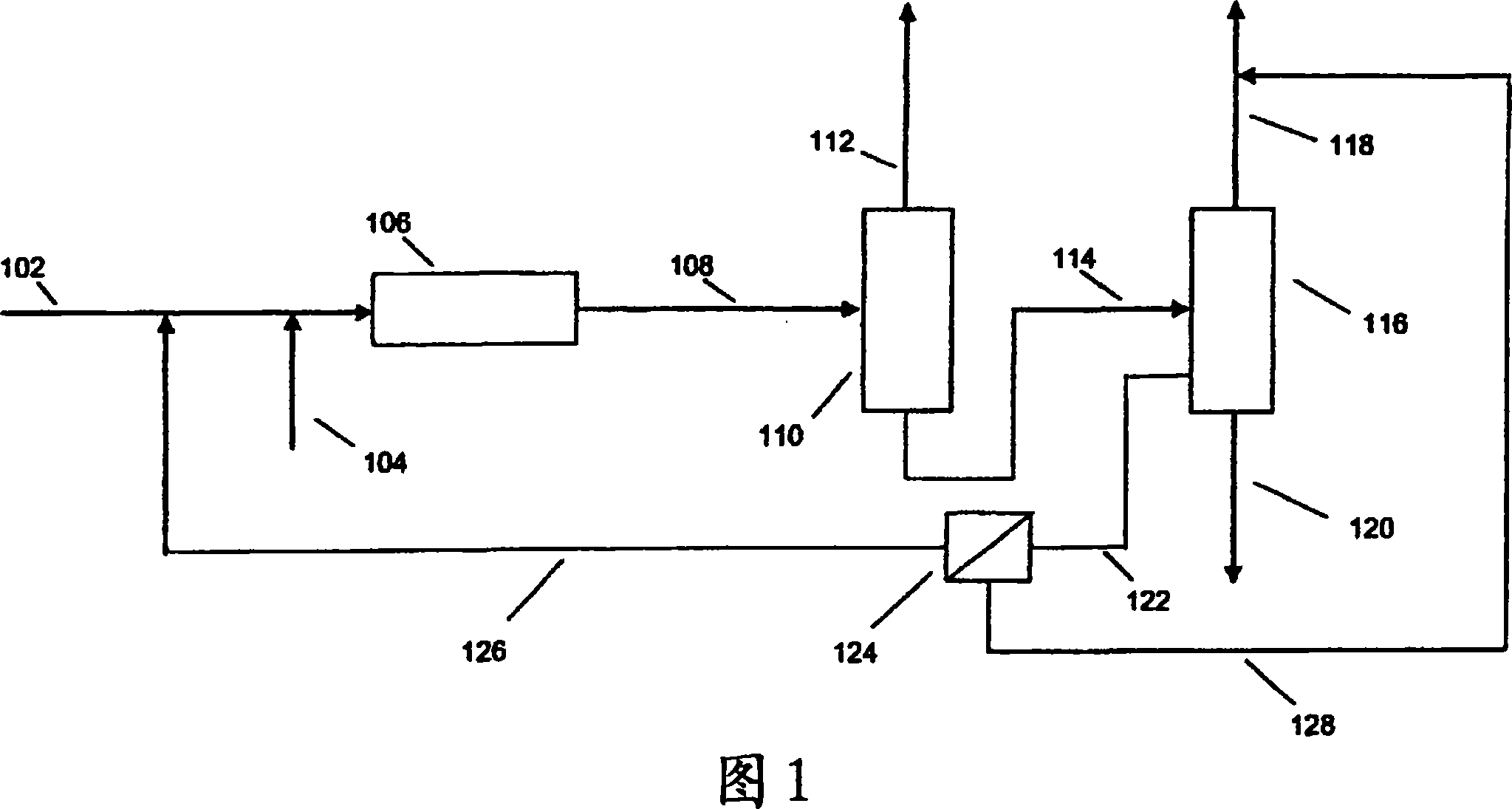

Image

Examples

Embodiment Construction

[0048] isomerisation

[0049] Any suitable paraffin-containing feedstock can be used in the process of the present invention. Naphtha feedstock is most commonly used as a feedstock for isomerization processes. The naphtha feedstock contains paraffins, naphthenes, and aromatics, and may contain small amounts of olefins in the gasoline boiling range. Feedstocks that may be used include straight run naphtha, natural gasoline, synthetic naphtha, thermal gasoline, catalytically cracked gasoline, partially reformed naphtha, or raffinate from aromatics extraction. The feedstock consists essentially of full range naphtha, or is in the boiling range of 0-230°C. Usually the feedstock is light naphtha with an initial boiling point of 10-65°C and a final boiling point of 75-110°C; preferably a final boiling point of less than 95°C.

[0050] Naphtha feedstocks generally contain small amounts of sulfur compounds totaling less than 10 parts per million by mass (mppm) on an elemental basis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com