Method for preparing degradable artificial ductulus lacrimalis

A canaliculus, artificial technology, applied in the direction of catheters, eye implants, etc., to achieve the effect of simple operation, uniform distribution, and easy demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

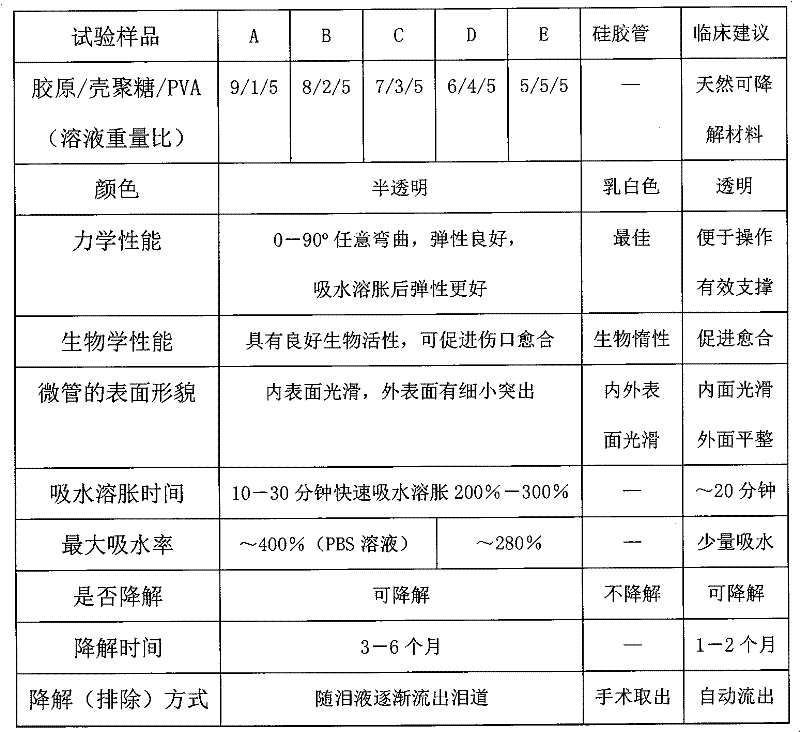

Method used

Image

Examples

Embodiment 1

[0048] A preparation method of degradable artificial lacrimal canaliculus is as follows:

[0049] Step 1. Dissolve the medical polyvinyl alcohol PVA-124 particles in water for injection in a water bath at 90°C to prepare a transparent 5-10% (w / w) polyvinyl alcohol solution;

[0050] The second step. Under room temperature conditions, the chitosan with deacetylation degree ≥ 90% is dissolved in 1 ~ 2% (w / w) acetic acid solution, stirred for 16 hours-24 hours, until fully dissolved, prepared into 2 ~4% (w / w) chitosan solution, refrigerated at 2°C to 8°C;

[0051] Step 3. Pepsin digestion, acetic acid solution extraction and washing of bovine Achilles tendon, from which extract type I collagen solution, concentration ≥ 0.5% (w / w), refrigerated at 2°C to 8°C;

[0052] The fourth step. Weigh 90g 1% collagen solution and 10g 2% chitosan solution, stir and mix in ice bath, add 50g 10% polyvinyl alcohol solution, stir for 1 hour and mix until the mixed solution forms a uniform transl...

Embodiment 2

[0064] Weigh 70g of 1% collagen solution and 30g of 2% chitosan solution, stir and mix in ice bath. Add 50g of 10% polyvinyl alcohol solution, continue to stir and mix until the mixed solution forms a uniform translucent viscous liquid, slowly add a little 2M NaOH solution dropwise while stirring, adjust the pH value of the solution to 7.08, continue to stir for half an hour, Let stand overnight. Use a syringe to draw a homogeneous mixed solution, put a needle on it, inject the solution into the mold, and then freeze / thaw repeatedly at -20°C / 20°C for 5 times, take out the elastic composite gel formed into a column, and insert a hard gel into the middle of the composite gel column. Make a hole with a round rod, put it into water for injection and wash it for 30 minutes, stand it upright, air-dry it at room temperature, remove the mold, trim both ends, and package, and the rest are the same as in Example 1.

Embodiment 3

[0066] Weigh 30g of 1% collagen solution and 20g of 2% chitosan solution, stir and mix in an ice bath, add 25g of 10% polyvinyl alcohol solution, continue to stir and mix until the mixed solution forms a uniform translucent viscous liquid. Slowly add a little 2M NaOH solution dropwise while stirring to adjust the pH value of the solution to 6.89, continue stirring for half an hour, and let stand overnight at low temperature. Use a syringe to draw the mixed solution, put a needle on it, inject the solution into the mold, then freeze / thaw 5 times at -20°C / 20°C, take out the columnar composite gel, and pass the 7# puncture needle through the gel column For the central axis, soak the needle-piercing gel column in ≤0.25% glutaraldehyde solution for 0.5 hours, take it out, rinse it repeatedly in water for injection, stand it upright, dry it naturally at room temperature, demould, cut both ends, encapsulate, and the rest with Example 1 is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com