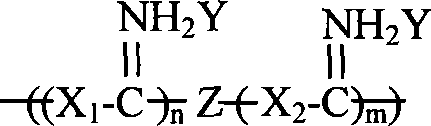

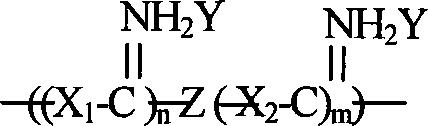

High molecular weight guanidine salt and polyamine antimicrobial polymeric compounds, producing method and application of the same

A high molecular weight, polyamine technology, used in textiles and papermaking, fiber processing, paper and other directions, can solve the problem of polyamines and guanidine salts that are difficult to obtain higher molecular weight polymers, and achieve short reaction time, good antibacterial effect, and reaction low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Take guanidinium hydrochloride (CH 5 N 3 .HCl) 100 grams, propylenediamine 70 grams, join in the 500 milliliters of round bottom flasks, under the protection of nitrogen, the reaction temperature is raised to 120 ℃, after the reaction is carried out for 1 hour, add 50 grams of adipic acid, continue to heat up to React at 140°C for 6 hours. When the reaction reaches 4 hours, vacuumize the vacuum to 5kPa to speed up the reaction. Stop the reaction after 6 hours. The reaction product is an antibacterial guanidinium salt polymer with a molecular weight of about 1.5 ×10 4 , the minimum inhibitory concentration is 125ppm.

Embodiment 2

[0030] Take 150 grams of guanidinium hydrochloride and 23 grams of hexamethylenediamine, and add them to a 500-milliliter round-bottomed flask. Under the protection of nitrogen, the reaction temperature is raised to 80° C. After the reaction is carried out for 10 hours, add 40 grams of adipic acid, and continue to heat up After reaching 200°C, react for 3 hours. During the reaction, vacuumize to make the vacuum reach 8kPa to accelerate the reaction. The reaction product is an antibacterial guanidinium polymer with a molecular weight of about 2.3×10 4 , the minimum inhibitory concentration is 50ppm. During the reaction, a vacuum is drawn to accelerate the reaction, and the reaction product is an antibacterial guanidinium salt polymer.

Embodiment 3

[0032] Take 120 grams of guanidinium nitrate, 30 grams of propylenediamine, and 50 grams of hexamethylenediamine, and add them to a 500-milliliter round-bottomed flask. After passing through nitrogen for half an hour, the reaction temperature is raised to 100 ° C. After 6 hours of reaction, add butanediamine 12 grams of acid anhydride, continue to heat up to 160 ° C, react for 2 hours, when the reaction is carried out for 3 hours, vacuumize to make the vacuum degree reach 10kPa to accelerate the reaction, and stop the reaction after the reaction is carried out for 6 hours, the reaction product is antibacterial guanidine salt Polymer with a molecular weight of about 2.0×10 4 , the minimum inhibitory concentration is 62ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com