Water-loss reducer using waste pouce or Chinese medicine slag and wastepaper as raw material, and production method thereof

A technology of traditional Chinese medicine residue and flax flakes, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of high cost, poor anti-fungal performance, difficult to degrade, etc., and achieve low cost, strong anti-fungal performance, and pollution reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

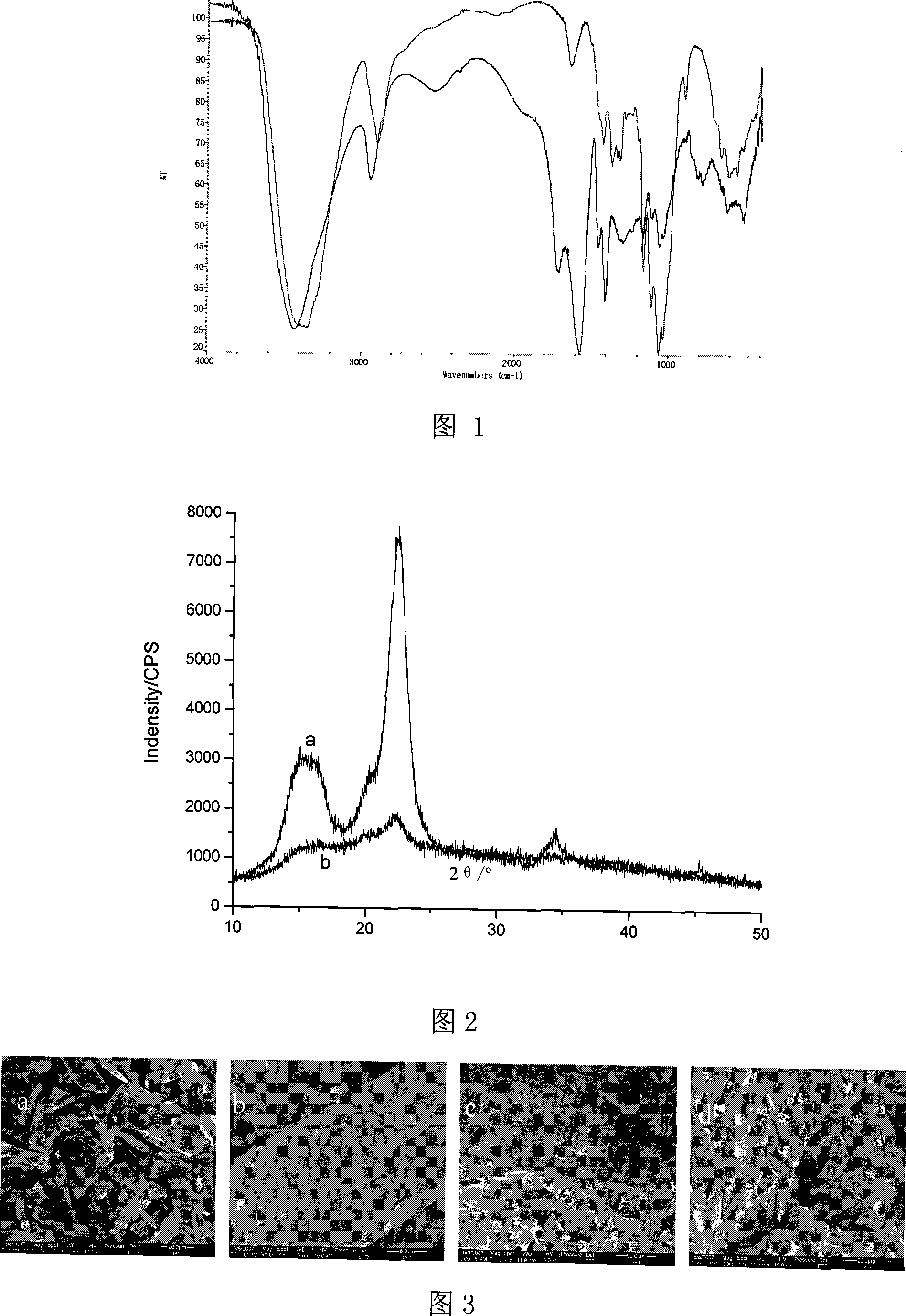

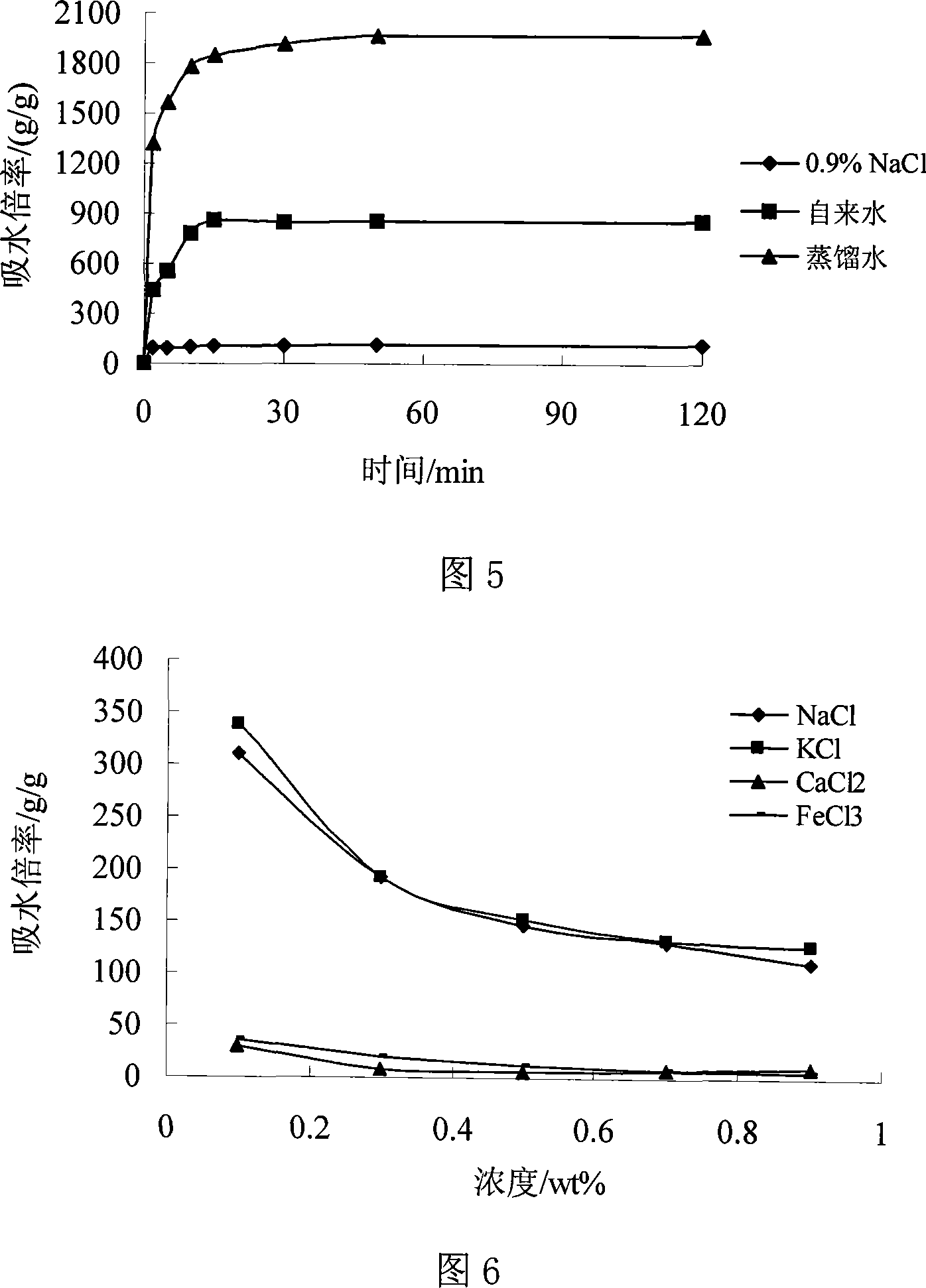

[0020] Specific implementation manner 1: This implementation manner is described in conjunction with FIG. 1 . This embodiment is made of cellulose powder, initiator, monomer and crosslinking agent extracted from waste flax or Chinese medicine residue and waste paper through chemical synthesis, and extracted from waste flax or Chinese medicine residue and waste paper by weight percentage The content of the cellulose powder is 8-17%, the initiator is 0.02-0.18%, the monomer is 83-89%, and the cross-linking agent is 0.06-0.4%.

specific Embodiment approach 2

[0021] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the cellulose powder extracted from discarded flax scraps or traditional Chinese medicine residue and waste paper is 10.5% by weight, the initiator is 0.1%, and the monomer is 89%. , The cross-linking agent is 0.4%.

specific Embodiment approach 3

[0022] Specific embodiment three: The difference between this embodiment and specific embodiment one is that the cellulose powder extracted from waste flax or traditional Chinese medicine residue and waste paper is 12%, the initiator is 0.05%, and the monomer is 87.75%. , The crosslinking agent is 0.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com