Central inflating and deflating control valve assembly for modeled cross-country vehicle tire

A technology for inflation and deflation control and automobile tires, which is applied in the directions of multi-way valves, valve devices, engine components, etc., can solve problems such as the structure of the control valve assembly that has not yet been found, and achieves simple structure, fewer pipeline arrangements, and enlarged air passages. The effect of the path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

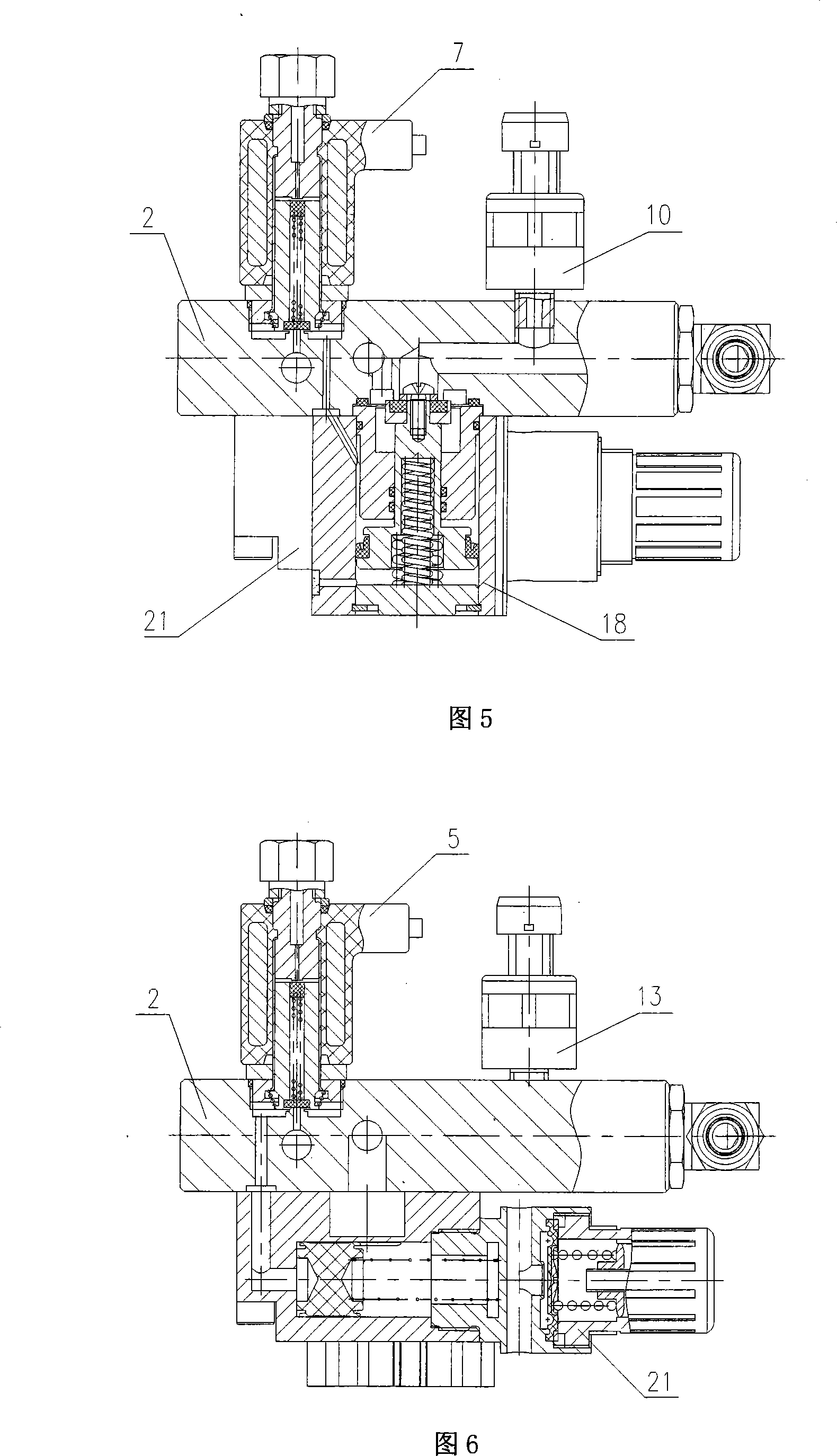

[0083] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0084] 1. Overall

[0085] The invention is an important part of the tire central inflation and deflation system of the off-road vehicle, and is matched with a special detection and control system.

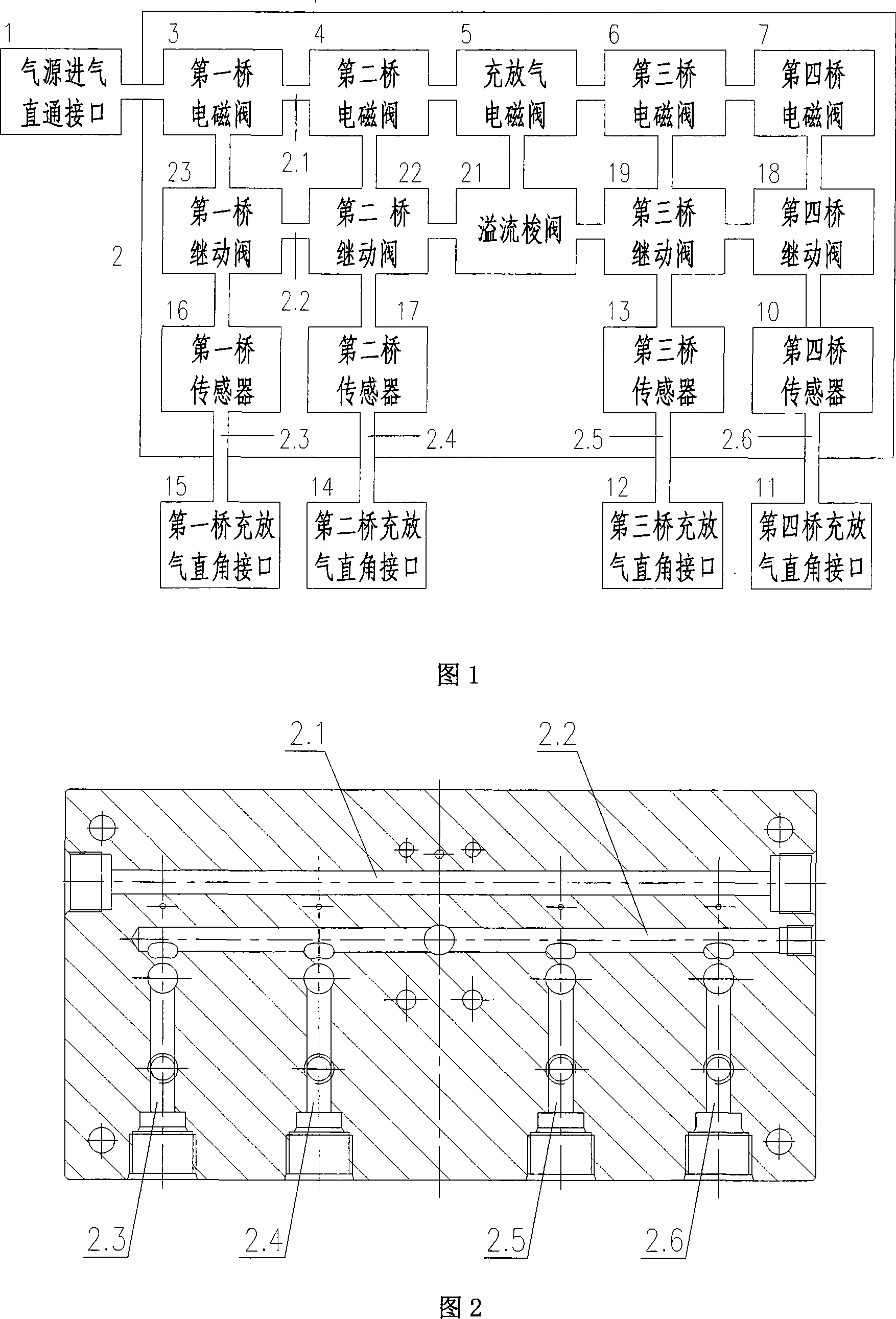

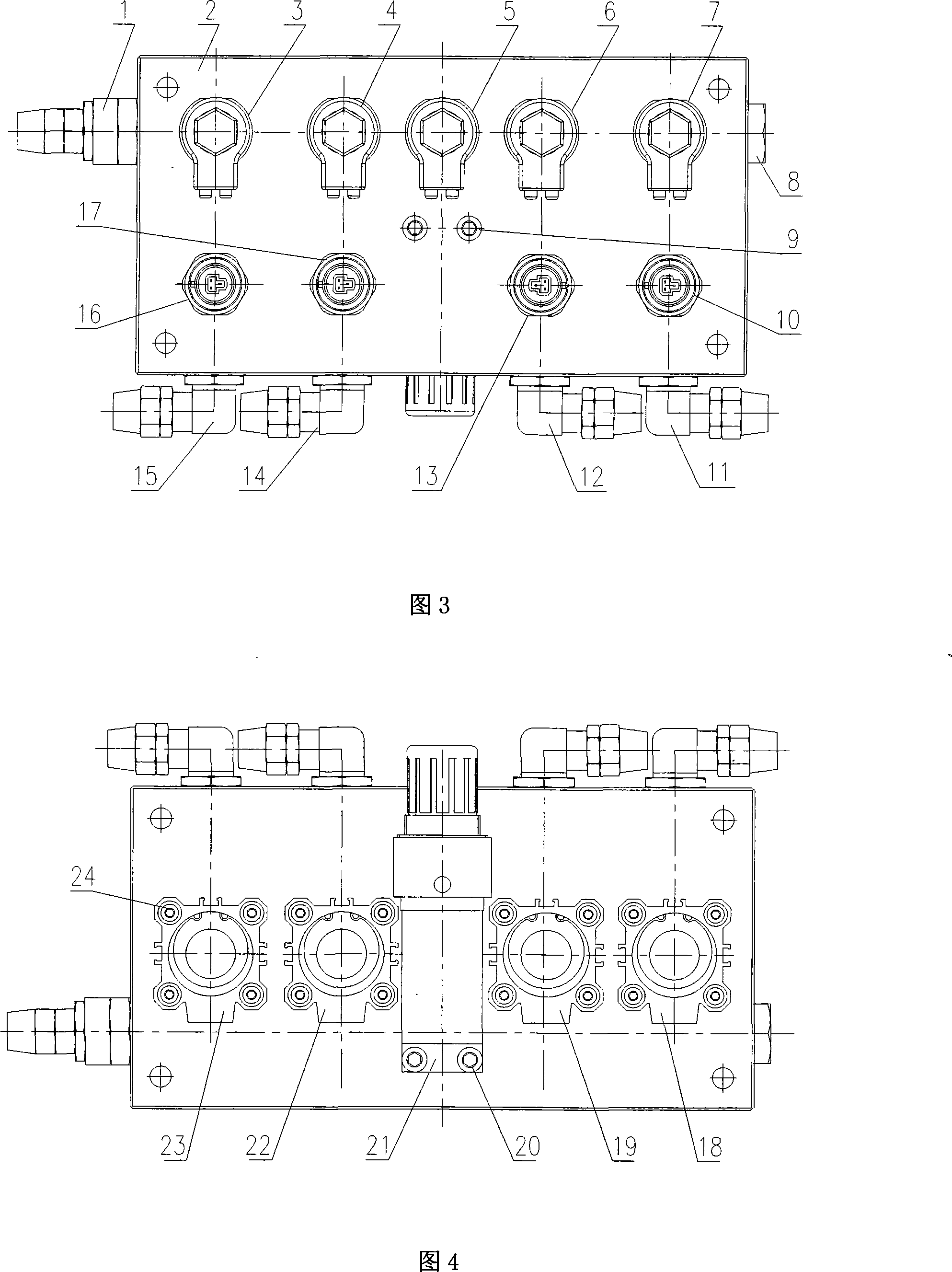

[0086] The number of axles of the off-road vehicle involved in the present invention includes 2 axles, 3 axles and 4 axles. The principle of its module structure is the same. In view of the difference in the number of bridges, it can be designed into 2 axles by increasing or decreasing the channels and valves on the modules. Module assembly, 3-axle module assembly and 4-axle module assembly. The above-mentioned assembly is a 4-axle assembly.

[0087] Two, each component

[0088] 1) Air source intake straight-through interface (1)

[0089] As shown in Figure 7, the air source intake straight-through interface (1) includes a locking sleeve (1.1), a straight-through joint (1.2), a first O-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com