Method for bioleaching metal containing sulphidic materials

A technology of biological leaching and sulfide, applied in the direction of improving process efficiency, etc., can solve unexpected problems and achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

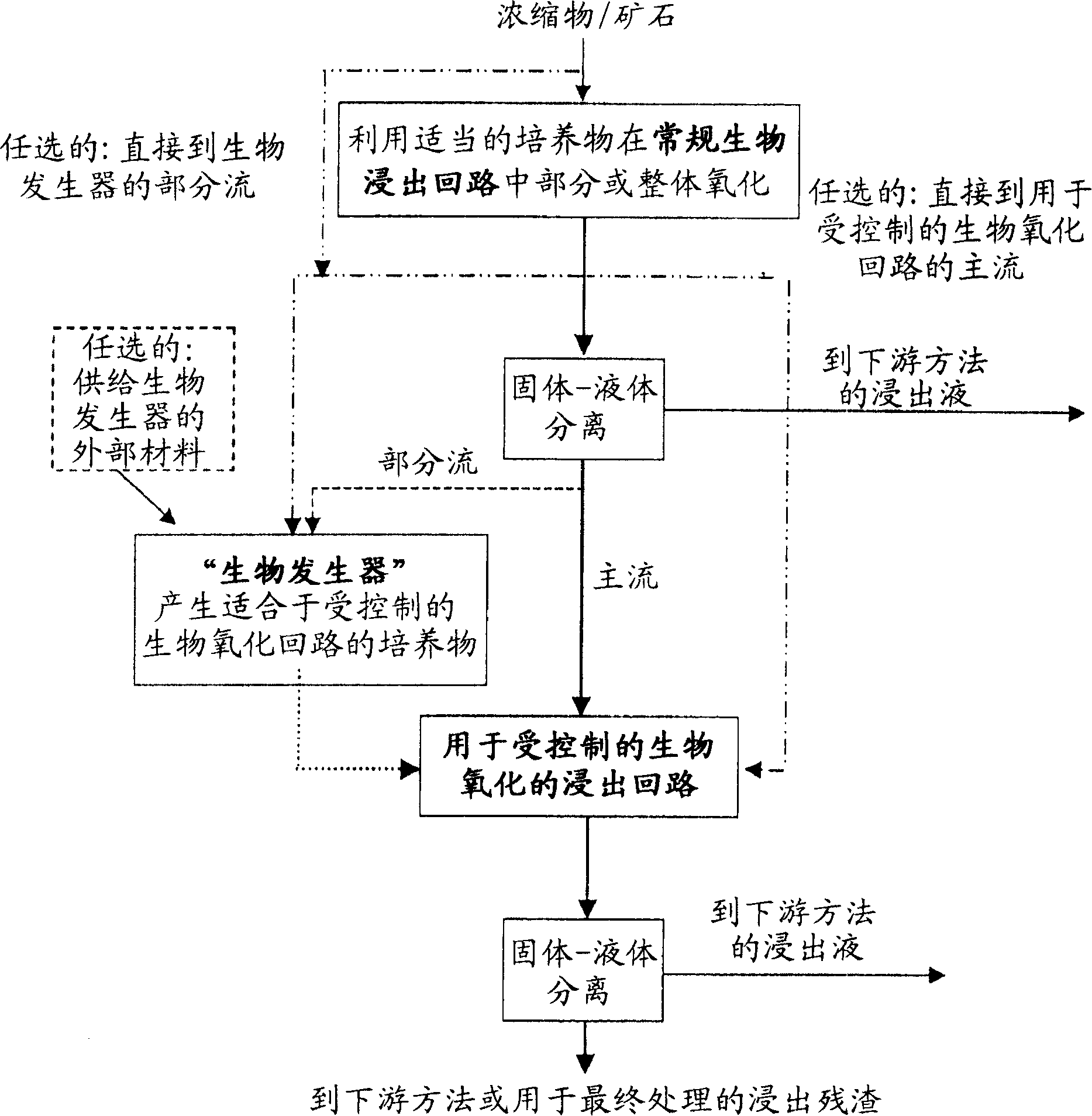

[0028] figure 1 A sketch of the general approach is shown in , where the concentrate / ore is first supplied in the form of a mainstream to a conventional bioleaching circuit for partial oxidation (bulk oxidation) with a culture suitable for this purpose. This partial oxidation can leach more lightly oxidized components such as zinc or arsenic. Alternatively the main flow may be fed directly or via a dehydration step to the subsequent main circuit, ie the leaching circuit of controlled biooxidation. A portion of the main flow is directed before or immediately after the preparative bioleaching loop and to a side loop consisting of a biogenerator producing biomass suitable for the controlled biomass in the main loop Oxidation, ie the amount of microorganisms with suitable type and amount. Alternatively, an external material of a different type than the material in the main flow may make up, in whole or in part, the incoming flow of this circuit. In the biogenerator, the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com