Air sword blower fan precision detection monitoring system

A technology of monitoring system and air knife, applied in general control system, control/adjustment system, computer control, etc., to achieve the effect of timely processing, scientific programming and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

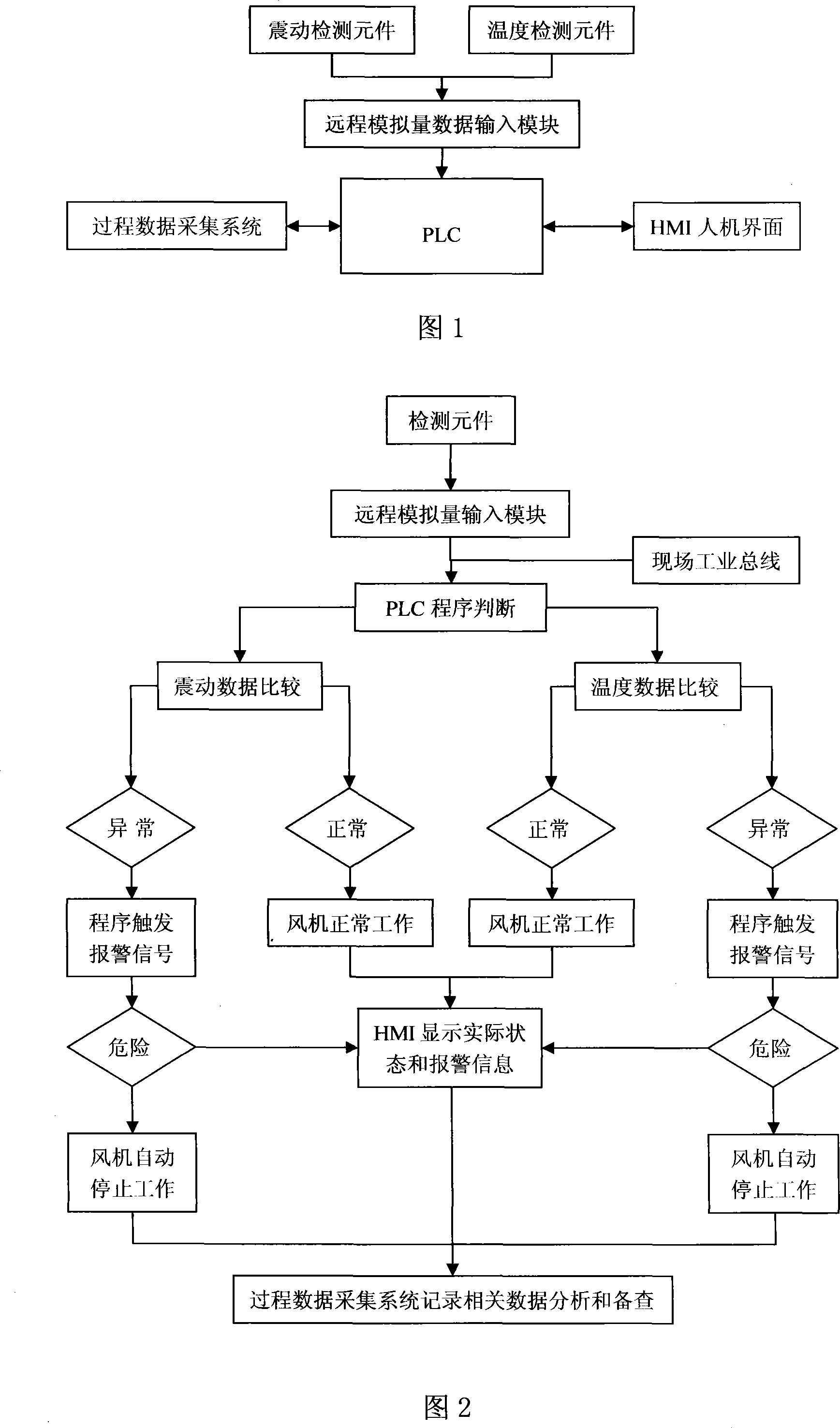

[0024] Depend on figure 1 It can be seen that the air knife fan precision detection and monitoring system is composed of detection components, remote analog data input system, PLC, HMI human-machine interface, and process data acquisition system.

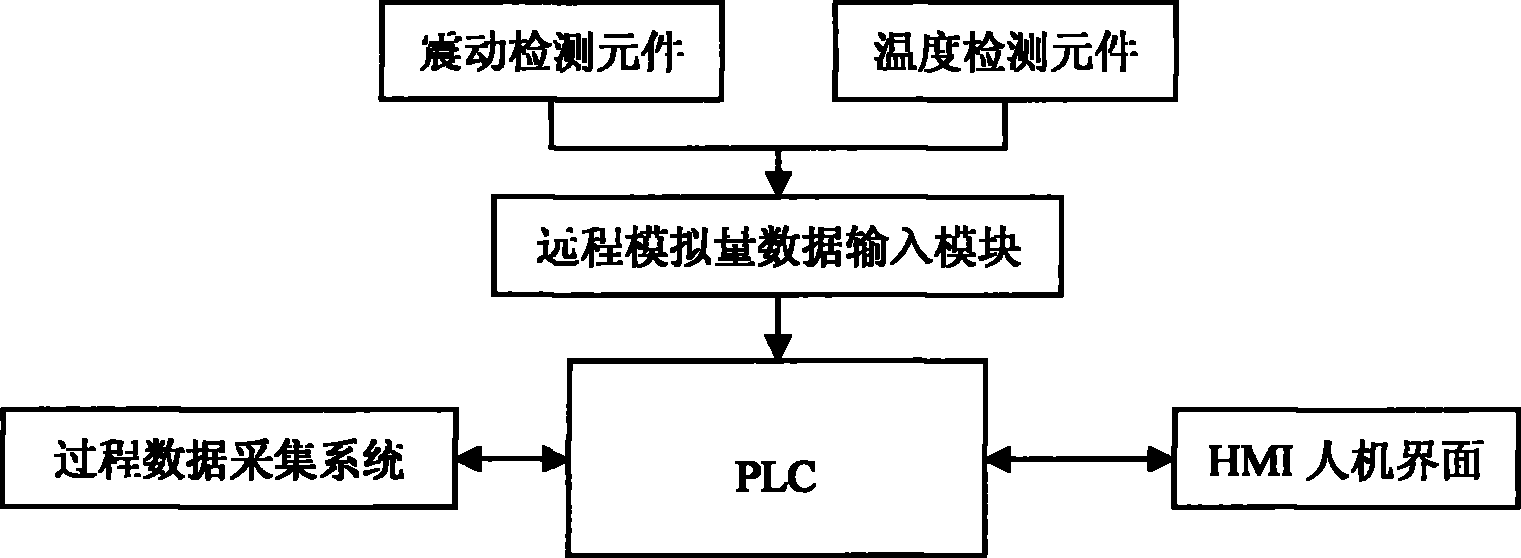

[0025] Air knife fan precision detection and monitoring system settings and detection and monitoring procedures such as figure 2 Shown:

[0026] Through the thermocouple (PT100) and vibration sensor (MTN / 1185CQ) installed on the inlet bearing and outlet bearing of the air knife fan, the detected temperature and vibration data are sent to the analog input module respectively.

[0027] The analog input module transmits the processing data to the PLC through the field bus.

[0028] PLC compares the temperature and vibration data with the normal value according to the programmed program.

[0029] When the detected temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com