Liquid crystal spacer, spacer diffusion liquid, liquid crystal display device manufacturing method, and liquid crystal display divice

A technology of a liquid crystal display device and a manufacturing method, which are applied in the directions of nonlinear optics, instruments, optics, etc., can solve the problems of satisfactory fixation of spacers and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

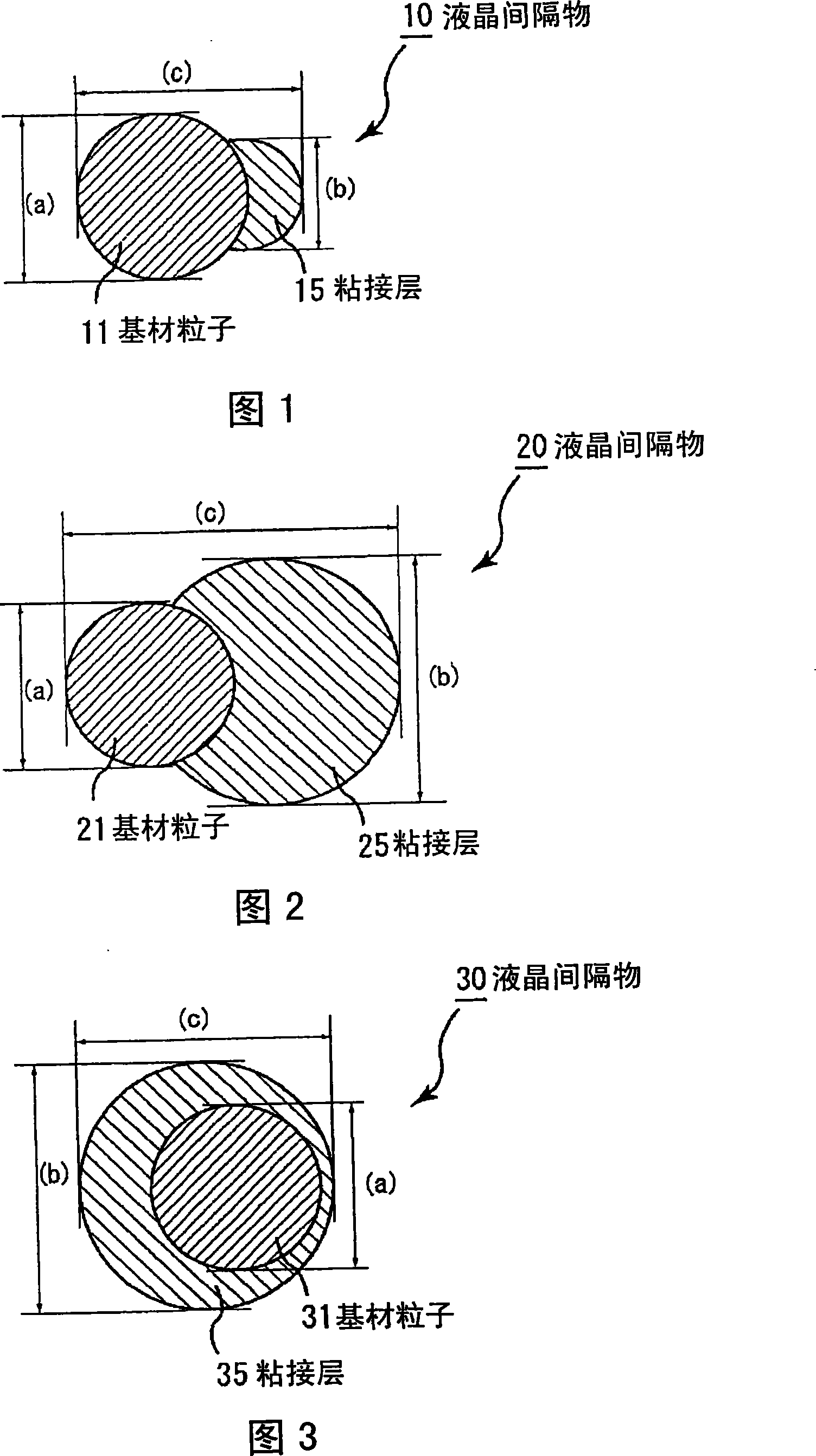

Image

Examples

Embodiment 1

[0416] As the substrate particles, particles having a particle diameter of 4.1 μm (CV 5%) mainly composed of divinylbenzene (trade name “Micropearl SP-2401”, manufactured by Sekisui Chemical Industry Co., Ltd.) were used.

[0417] In a separable flask, weigh 80 parts by weight of ion-exchanged water, 320 parts by weight of ethanol, 0.5 parts by weight of polyvinylpyrrolidone (K-30), 5 parts by weight of styrene, and 10 parts by weight of substrate particles, and mix them uniformly , to obtain a substrate particle dispersion.

[0418] Then, a solution uniformly mixed with 10 parts by weight of ion-exchanged water, 40 parts by weight of ethanol, and 0.8 parts by weight of 2,2'-azobisisobutyronitrile was put into the substrate particle dispersion, and polymerized at 60°C for 20 hours. , washed to obtain the shell seed particle (1) having the shell seed layer on the surface of the substrate particle.

[0419] As a result of measuring the particle size of the obtained seed shell p...

Embodiment 2

[0426] In addition to using the shell seed particles (1) obtained in Example 1, when preparing the polymerizable monomer emulsion, 160 parts by weight of ion-exchanged water, 0.2 parts by weight of ethylene glycol dimethacrylate, and methyl Polymerization of 0.8 parts by weight of 2-ethylhexyl acrylate, 0.2 parts by weight of hydroxyethyl methacrylate, 0.05 parts by weight of benzoyl peroxide, and 1.2 parts by weight of sodium dodecylsulfonate with a homogenizer A liquid crystal spacer (2) having an adhesive layer was obtained in the same manner as in Example 1 except for the monomer emulsion.

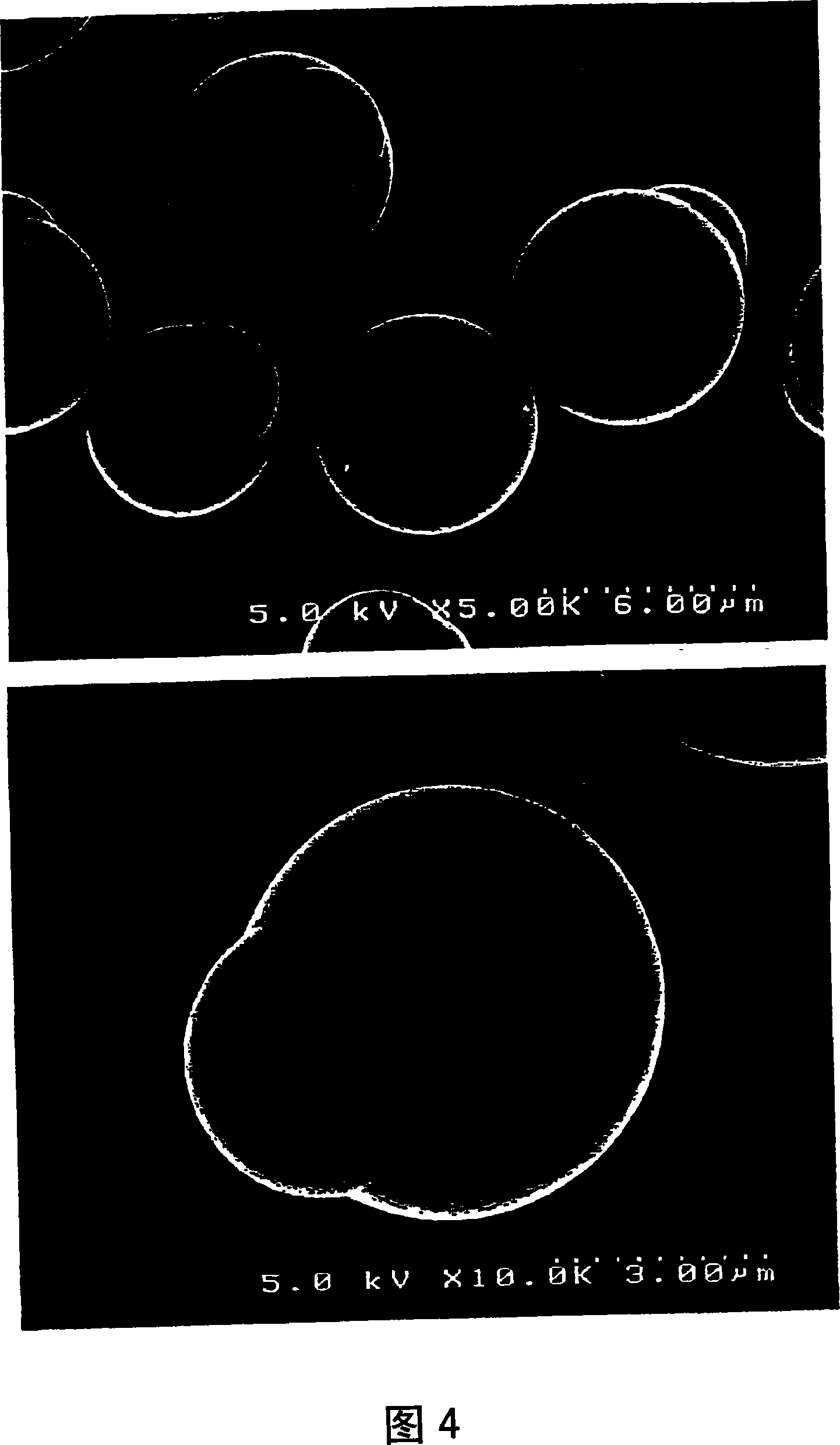

[0427] The cross section of the obtained liquid crystal spacer (2) was observed with a transmission electron microscope (TEM). As a result, as shown in FIG. 4, (a) was 4.2 μm, (b) was 6.1 μm, (b) / ( a) is 1.5, (c) is 7.2 μm, and a structure in which an adhesive layer is provided on a part of the surface of the substrate particle. Thereafter, a spacer dispersion liquid (2) was prepared ...

Embodiment 3

[0429] In addition to using the seed shell particles (1) obtained in Example 1, when preparing the polymerizable monomer emulsion, 160 parts by weight of ion-exchanged water, 0.6 parts by weight of ethylene glycol dimethacrylate, and methyl Polymerization of 2.4 parts by weight of 2-ethylhexyl acrylate, 0.6 parts by weight of hydroxyethyl methacrylate, 0.15 parts by weight of benzoyl peroxide, and 1.2 parts by weight of sodium dodecylsulfonate with a homogenizer A liquid crystal spacer (3) having an adhesive layer was obtained in the same manner as in Example 1 except for the monomer emulsion.

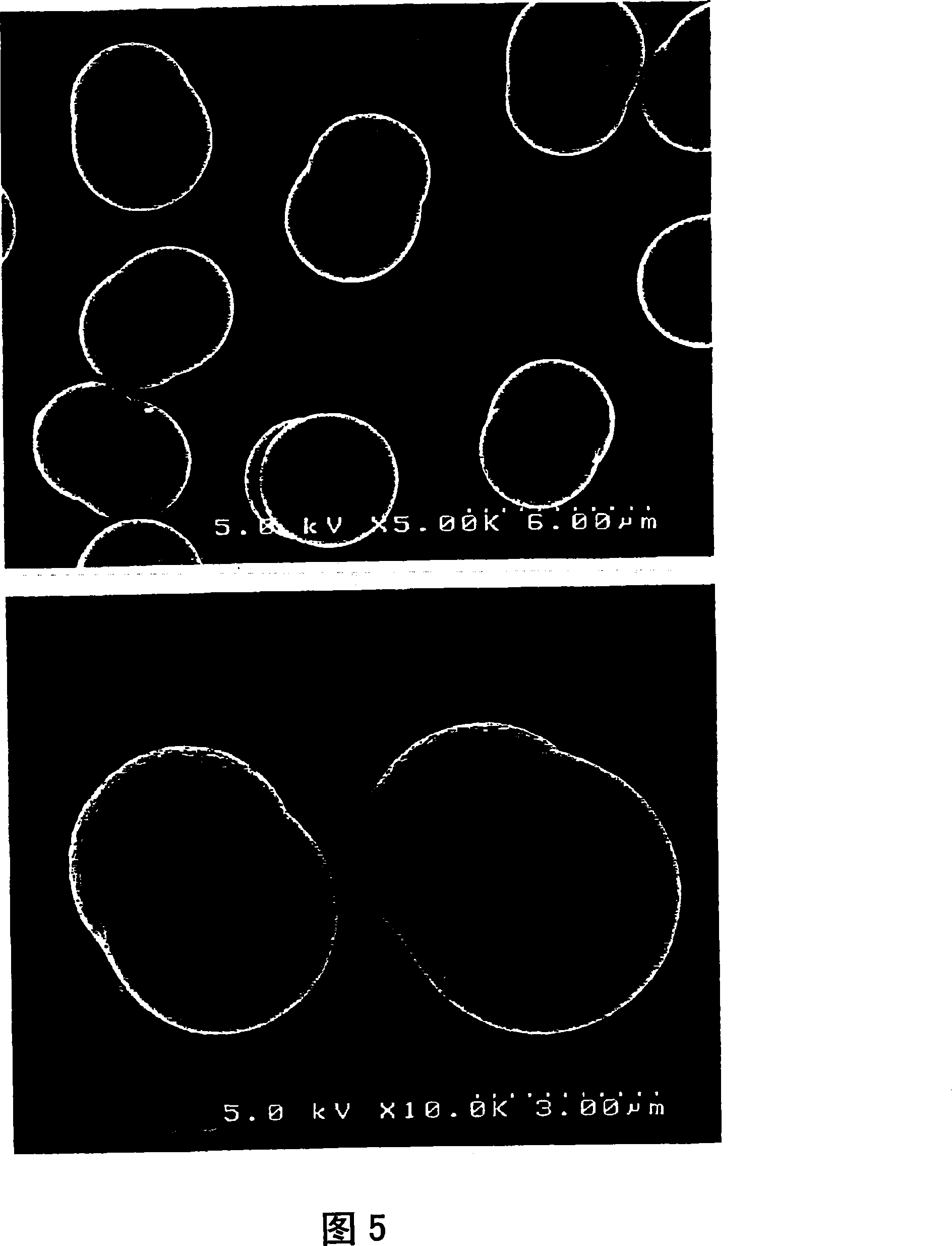

[0430] The cross-section of the obtained liquid crystal spacer (3) was observed with a transmission electron microscope (TEM). The results are shown in FIG. 5, (a) is 4.2 μm, (b) is 4.5 μm, (b) / (a ) is 1.1, (c) is 5.1 μm, and it is a structure in which an adhesive layer is provided on a part of the surface of the substrate particle. Thereafter, a spacer dispersion liquid (3) was prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com