Etchant for substrates having BPSG and SOD layers

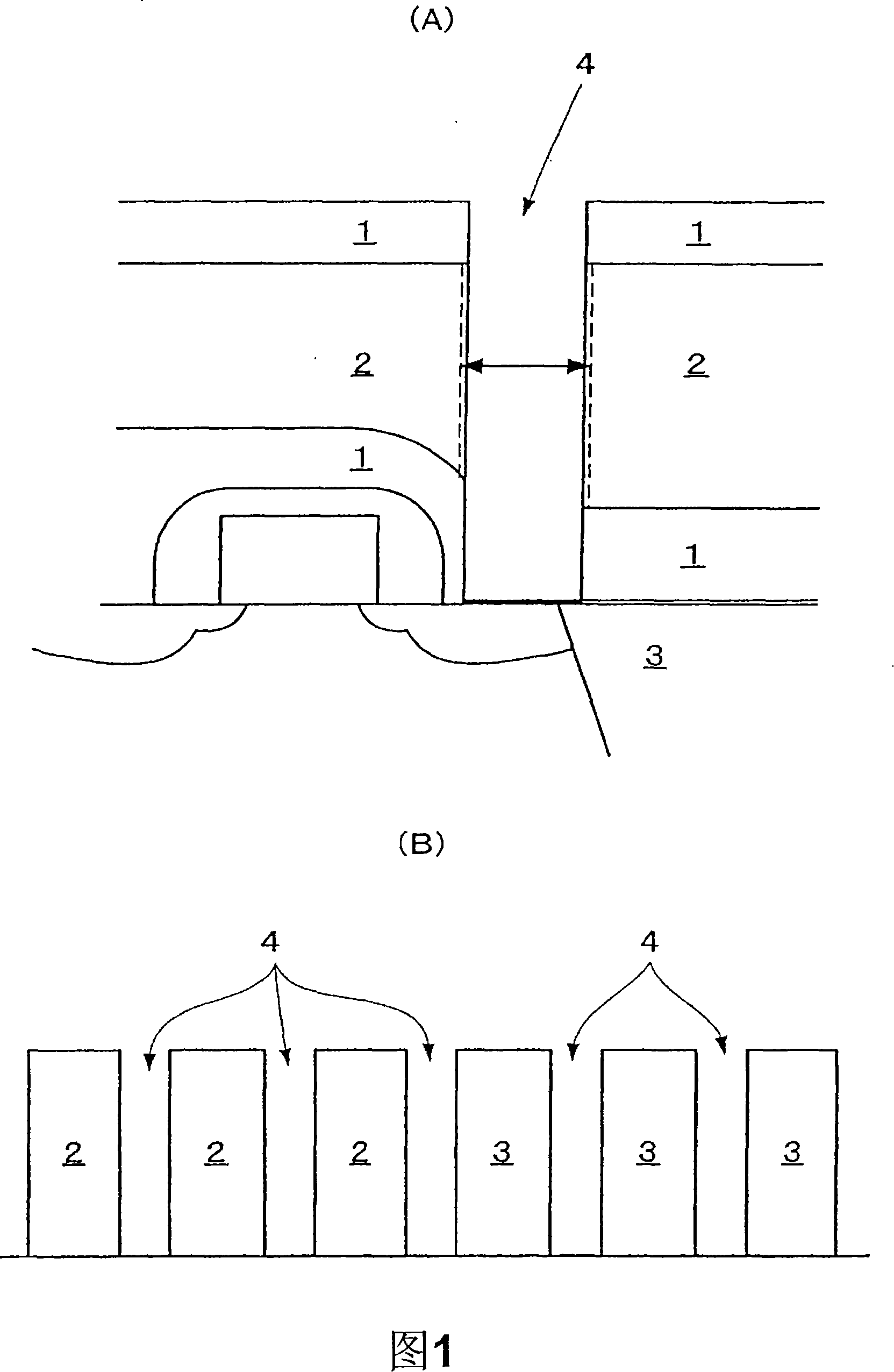

An etching solution and etching rate technology, which is applied in the manufacture of electrical components, circuits, semiconductor/solid-state devices, etc., can solve the problem of inappropriate etching solution for ultra-fine devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~17 and comparative example 1~12

[0082] According to the ratio shown in Table 1, mix difluoride salt (CH 3 NH 3 ·HF 2 or (CH 3 ) 3 NH·HF 2 ), water and organic solvents with heteroatoms, prepared etching solution, for the formation of non-annealing BPSG (borophosphorous glass) film, non-annealing SOD (spin-on-coating dielectric) film, thermal oxidation film (THOX) on the silicon substrate Any one of the test substrates was used to obtain the etching rate and selectivity ratio.

[0083] The results are shown in Table 1 and Table 2.

[0084] Table 1

[0085] solvent

Fluoride salt

Amount added

water

Etching rate (100A / min)

selection ratio

Solvent name

molecular formula

(℃)

(mol / kg)

(mol / kg)

(weight%)

THOX

BPSG

SOD

BPSG /

THOX

SOD /

THOX

Example 1

THF

CH2CH2CH2CH2O

-17.2

CH3NH3HF2

0.02

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com