Sucrose succedaneum and preparation method thereof

A substitute, sucrose technology, applied in the formulation and preparation of sucrose substitute sweeteners, can solve problems such as unacceptable taste, uneven mixing, bad taste of sweetness, etc., and achieve easy control of preparation conditions and difficulty in absorbing Moisture and caking, the effect of easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

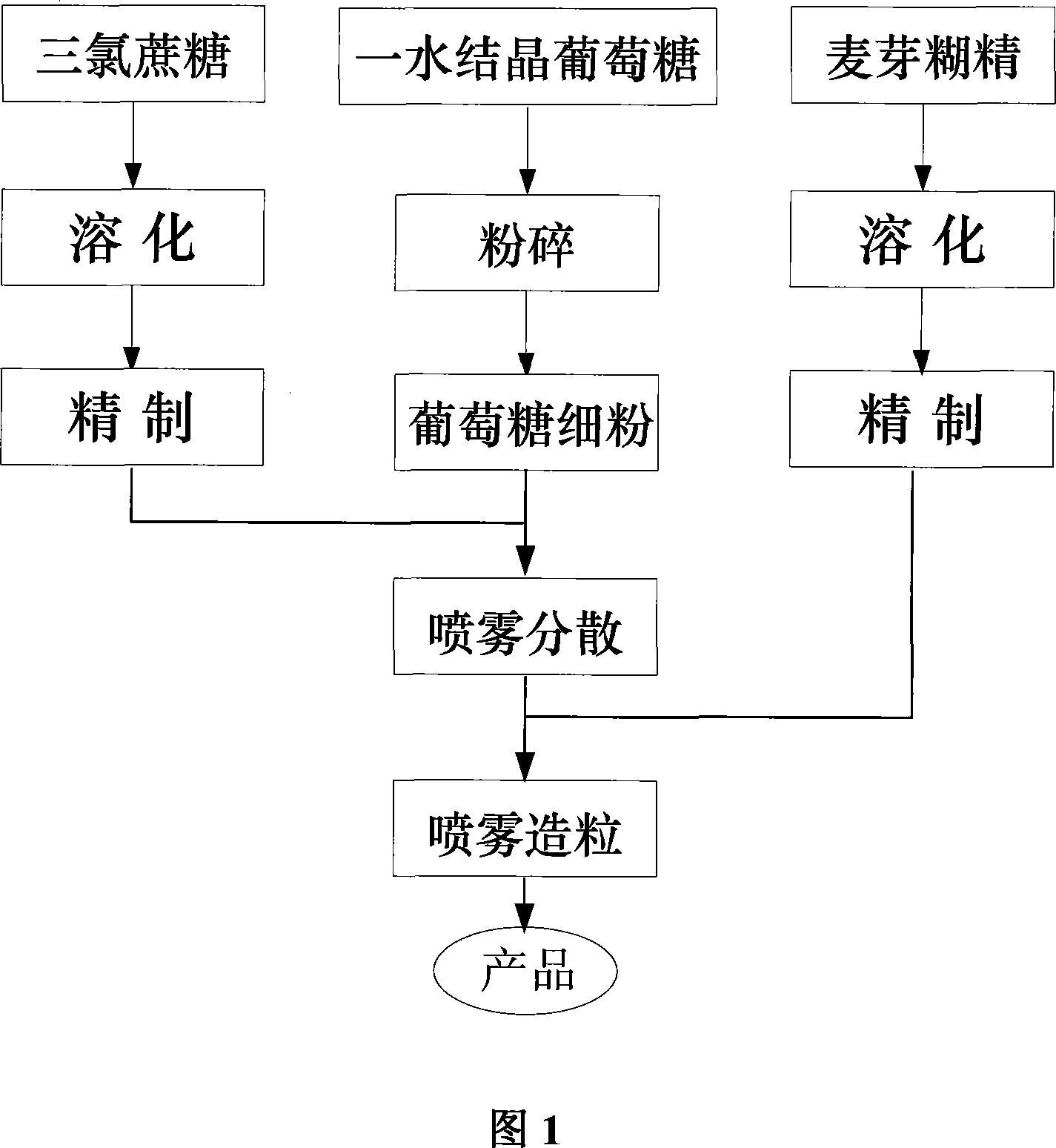

Method used

Image

Examples

Embodiment 1

[0024] Melt 3 kg of maltodextrin and 25 kg of deionized water in a stainless steel reaction pot, and dissolve 1.2 kg of sucralose and 20 kg of deionized water in a stainless steel reaction pot. The materials in the pot are heated to 65°C by the jacket. Start stirring, add 0.2 kg of activated carbon respectively, keep warm for 45 minutes, and filter while it is hot. In the fluidized bed equipment, control the temperature of the fluidized bed at 30-35°C, first pump in the above-mentioned refined sucralose solution, spray and disperse evenly, and after the operation is completed, raise the bed temperature to 70-75°C, After the water of crystallization is completely lost, pump the above-mentioned refined maltodextrin solution, continuously spray and granulate, control the air volume and spray flow rate, and obtain granular products with surface modification.

Embodiment 2

[0026] Melt 2 kg of maltodextrin and 25 kg of deionized water in a stainless steel reaction pot, and dissolve 0.5 kg of sucralose and 20 kg of deionized water in a stainless steel reaction pot. The materials in the pot are heated to 40°C by the jacket. Start stirring, add 0.2 kg of activated carbon respectively, keep warm for 40 minutes, and filter while it is hot. In the fluidized bed equipment, control the temperature of the fluidized bed at 35-45°C, first pump in the above-mentioned refined sucralose solution, spray and disperse evenly, and then increase the bed temperature to 45-85°C after the operation is completed, After the water of crystallization is completely lost, pump the above-mentioned refined maltodextrin solution, continuously spray and granulate, control the air volume and spray flow rate, and obtain granular products with surface modification.

Embodiment 3

[0028] Dissolve 8 kg of maltodextrin and 23 kg of deionized water in a stainless steel reaction pot, and dissolve 3 kg of sucralose and 18 kg of deionized water in a stainless steel reaction pot. The materials in the pot are heated to 80°C by the jacket. Start stirring, add 0.3 kg of activated carbon respectively, keep warm for 60 minutes, filter while hot, and collect the filtrates in jacketed storage tanks for use; In the fluidized bed equipment, control the temperature of the fluidized bed at 30-45°C, first pump in the above-mentioned refined sucralose solution, spray and disperse evenly, and after the operation is completed, raise the bed temperature to 75-80°C, After the water of crystallization is completely lost, pump the above-mentioned refined maltodextrin solution, continuously spray and granulate, control the air volume and spray flow rate, and obtain granular products with surface modification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com