Solar thermal-collecting tube reaction grid voltages feed back intelligent control method and apparatus

A solar collector tube and voltage feedback technology, applied in the field of solar collector tubes, can solve the problems of complex parameter setting and large voltage fluctuation, and achieve the effect of improving the degree of automation, accurate control and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

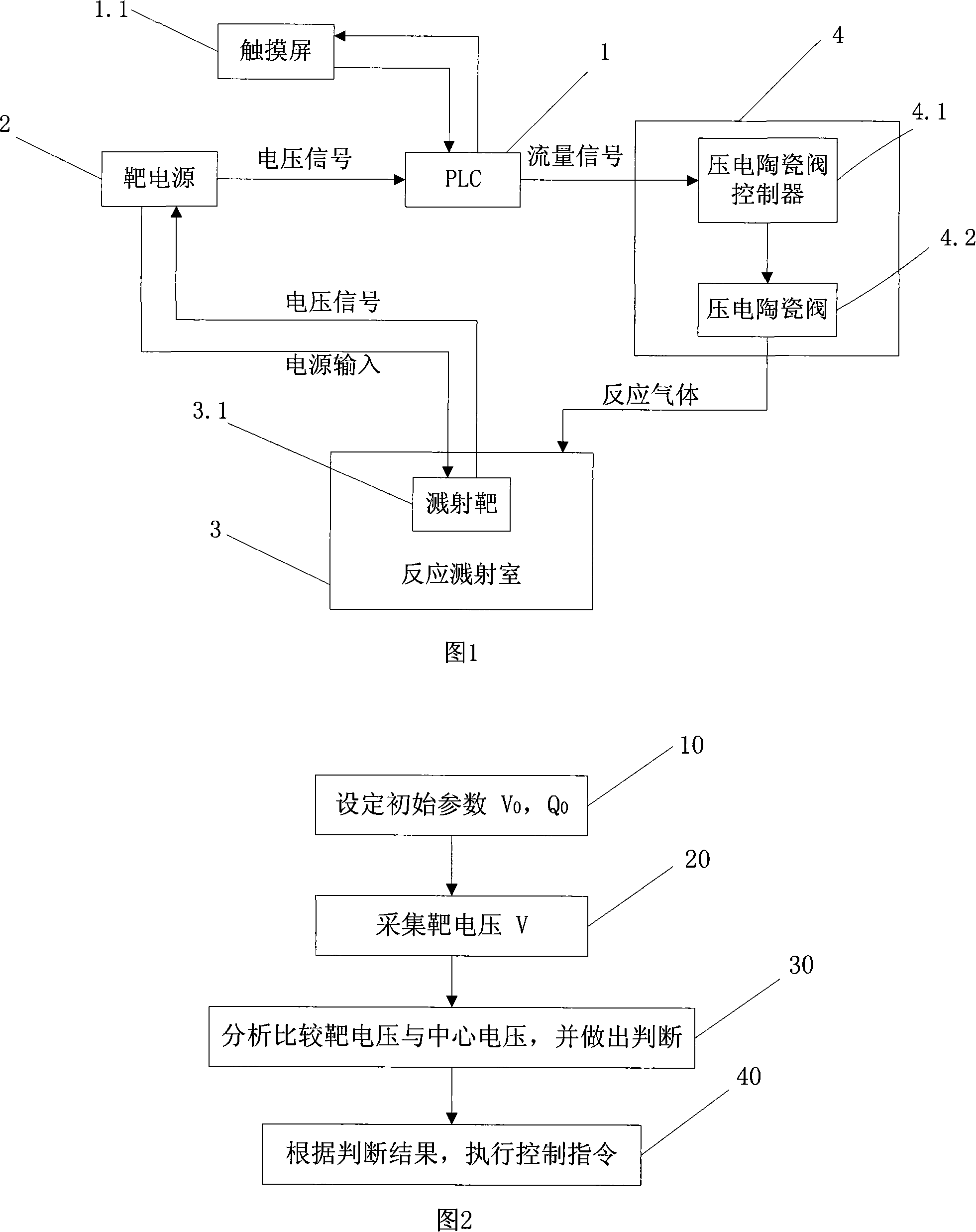

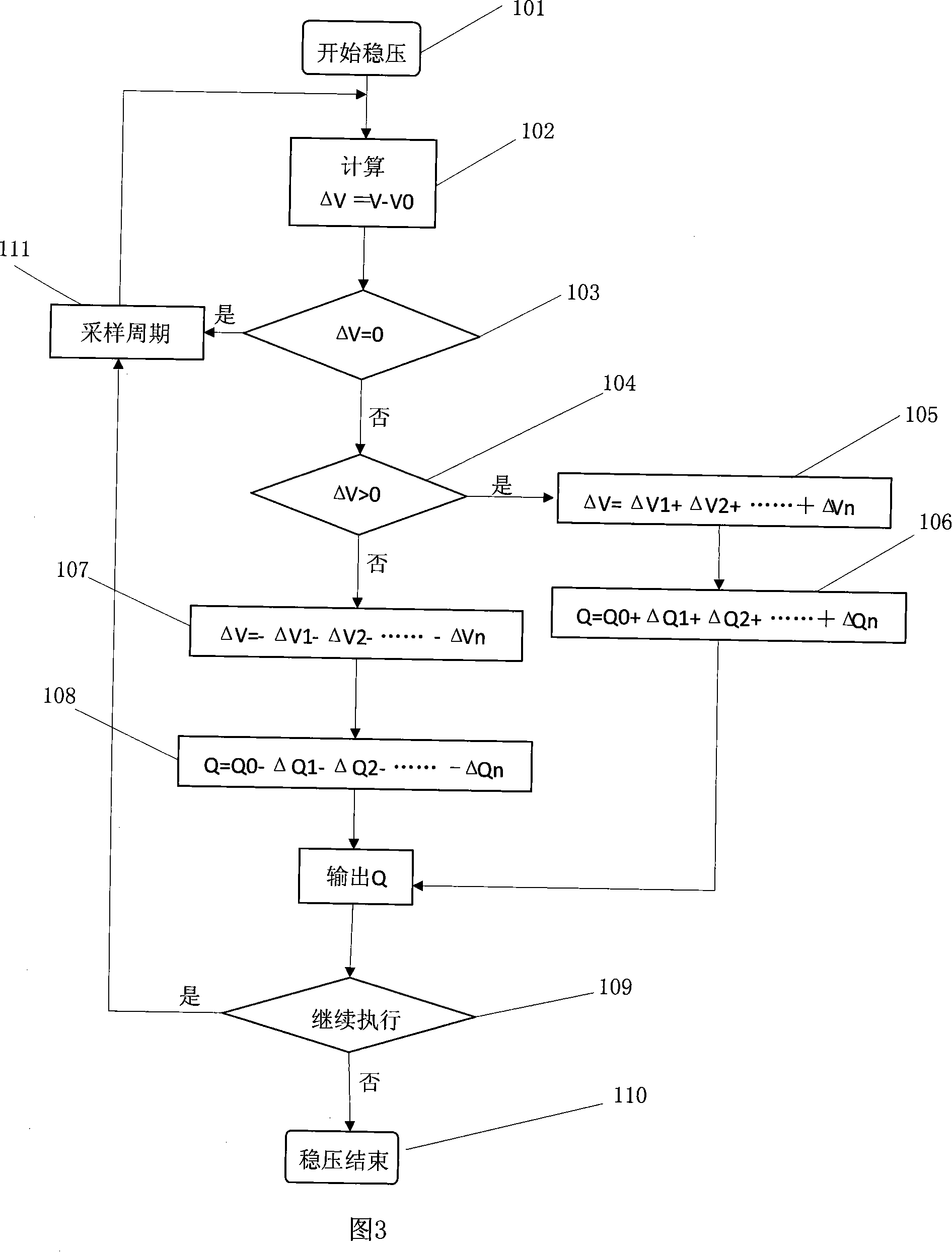

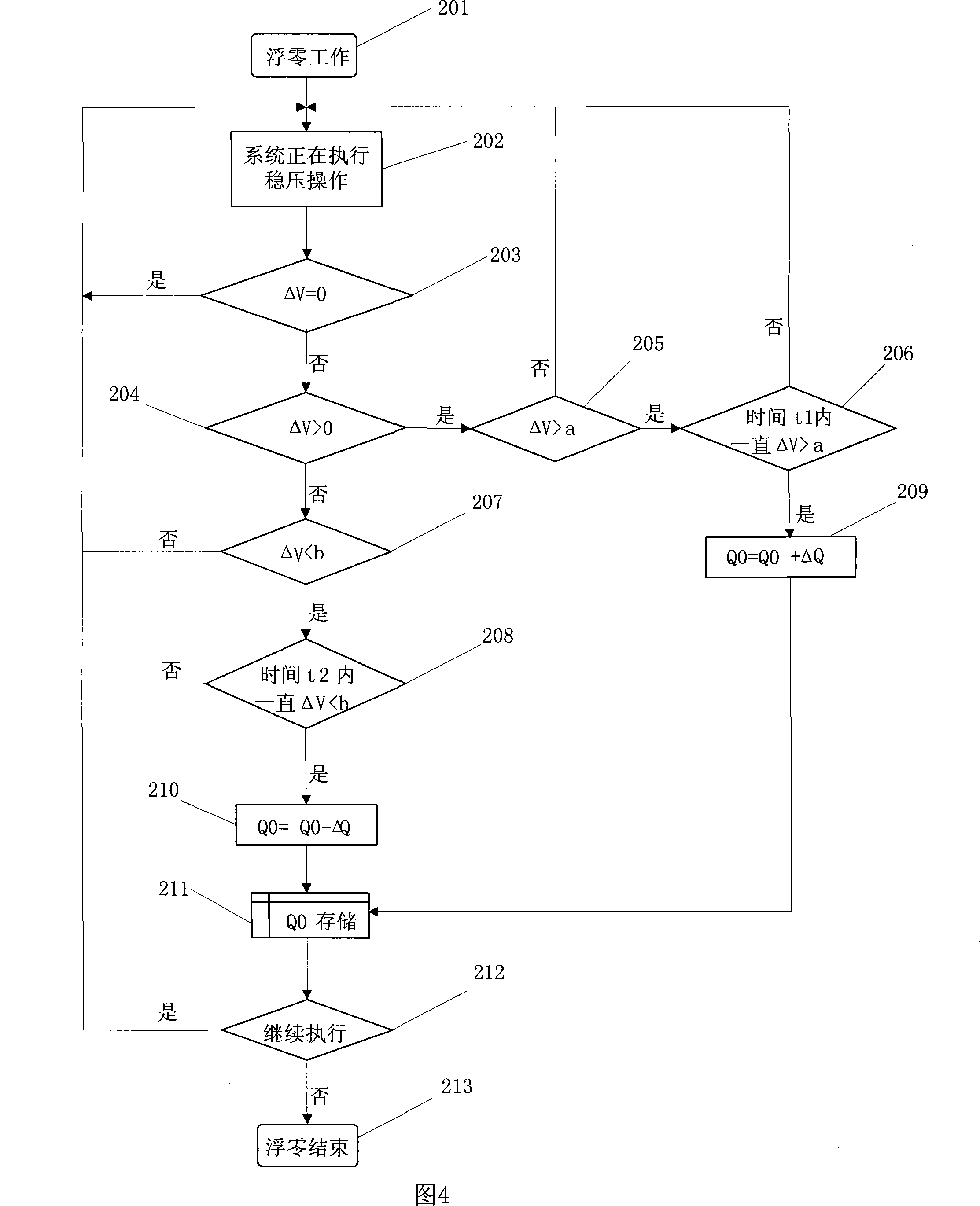

[0048] As shown in Figure 1, a solar collector tube reactive sputtering voltage feedback intelligent control device includes a target power supply 2, a control unit 1 and an air charging unit 4, and the control unit 1 is connected to and controls the target power supply 2 and the air charging unit 4 respectively. The target power supply 2 is an intermediate frequency power supply with a voltage feedback function, which is used to transmit the voltage signal of the sputtering target 3.1 in the reactive sputtering chamber 3 to the control unit 1 in real time. The control unit 1 is used to analyze and compare the collected voltage data and adjust the flow of gas flowing into the reaction sputtering chamber 3 accordingly. It includes a PLC control chip and a touch screen 1.1 connected thereto. The PL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com