Method for preparing (100) preferred orientation bismuth ferrite thin film

A preferred orientation, bismuth ferrite technology, applied in chemical instruments and methods, bismuth compounds, iron compounds, etc., can solve the problems of uneven particle distribution, complex film process, no preferred orientation, etc., to achieve uniform particle distribution, process Simple, excellent ferromagnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

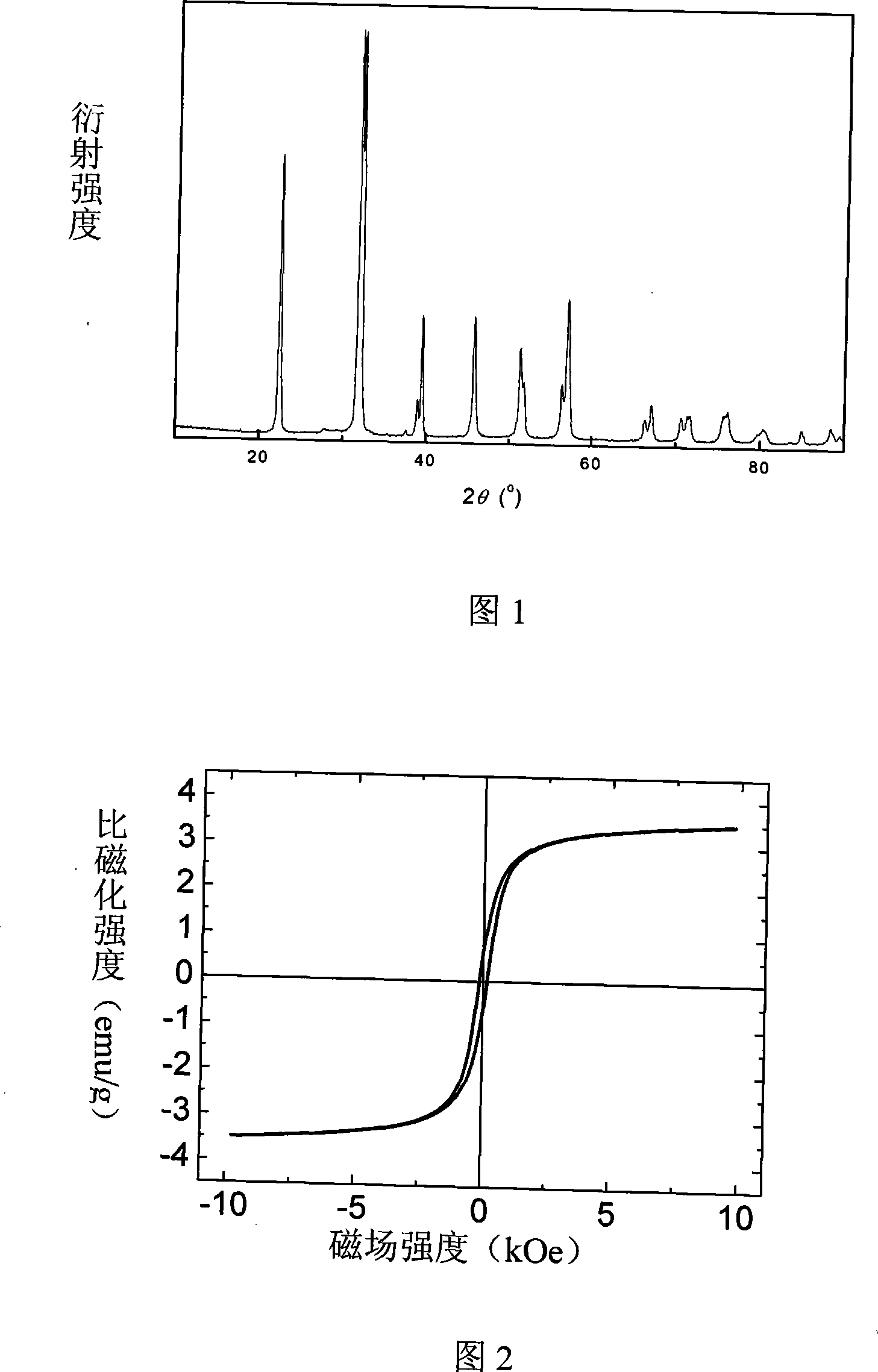

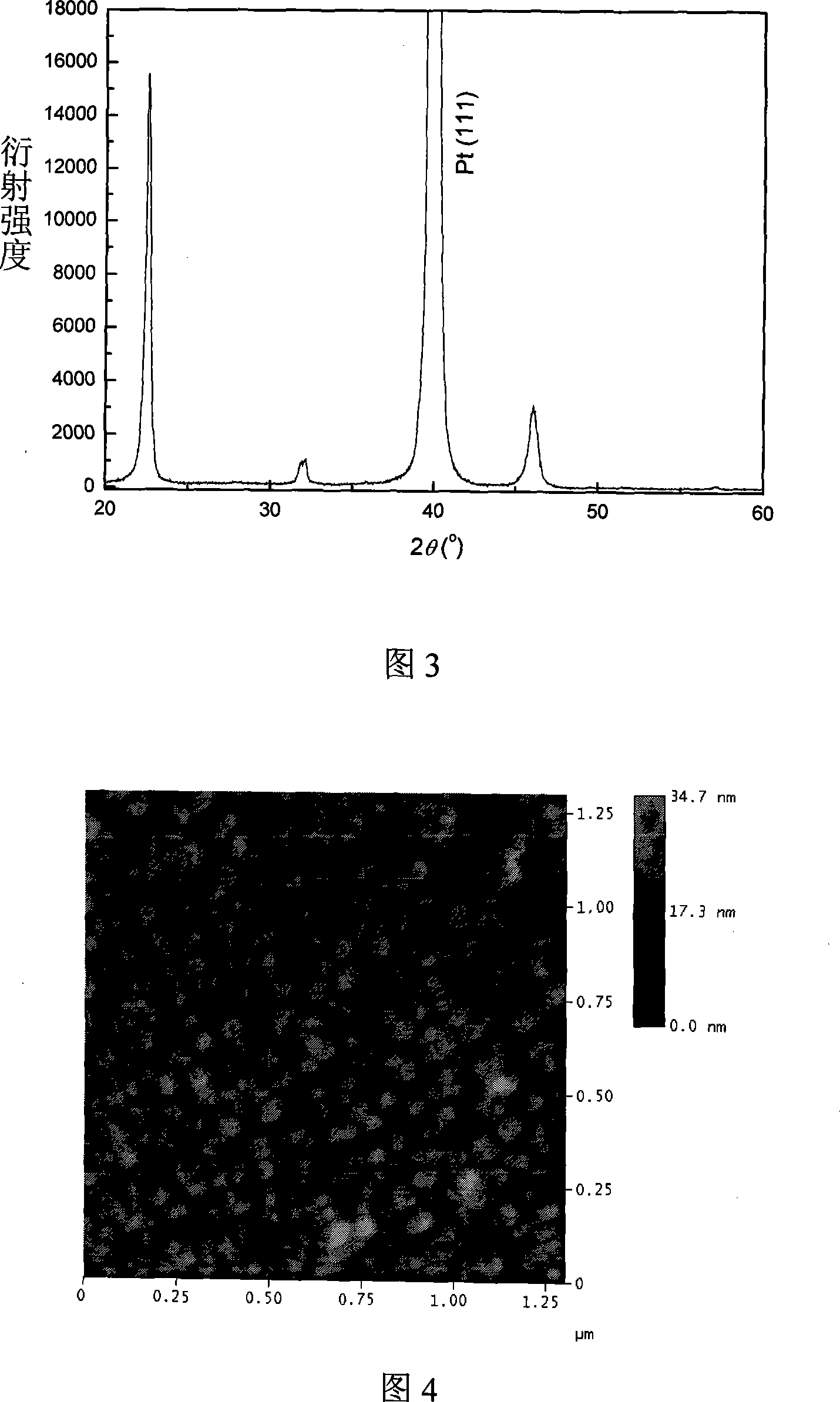

[0009] Specific embodiment one: the preparation method of a kind of (100) preferred orientation bismuth ferrite film of this embodiment is implemented according to the following steps: a, ferric nitrate and acetic acid are mixed by 1: 10~80 molar ratio, then slowly add concentration is 99.0 ~99.8% ethylene glycol solution, so that the molar ratio of iron ion and ethylene glycol in the solution is 1:5~18, and then stir for 8~12min; b. Mix bismuth subnitrate and acetic acid in a molar ratio of 1:50~400 , then slowly add the ethylene glycol solution with a concentration of 99.0 to 99.8%, so that the molar ratio of bismuth ions and ethylene glycol in the solution is 1: 5 to 18, and then stir for 8 to 12 minutes; c, the prepared by steps a and b The solutions were mixed, and then stirred for 20-40 minutes to obtain BiFeO 3 Sol; d, the Pt / Ti / SiO 2 / Si substrates were ultrasonically cleaned in acetone and absolute ethanol for 4 to 6 minutes, and dried; e, the BiFeO 3 The sol was sp...

specific Embodiment approach 2

[0011] Specific embodiment two: the difference between this embodiment and specific embodiment one is that ferric nitrate and acetic acid are mixed by 1: 40 molar ratio in step a, then slowly add the ethylene glycol solution that concentration is 99.5%, make iron ion in the solution and The molar ratio of ethylene glycol was 1:10, and stirred for another 10 minutes. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0012] Specific embodiment three: the difference between this embodiment and specific embodiment one is that in step b, bismuth subnitrate and acetic acid are mixed in a molar ratio of 1:200, and then slowly add a concentration of 99.5% ethylene glycol solution to make bismuth in the solution The molar ratio of ions to ethylene glycol was 1:10, and stirred for another 10 minutes. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Residual magnetization | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com