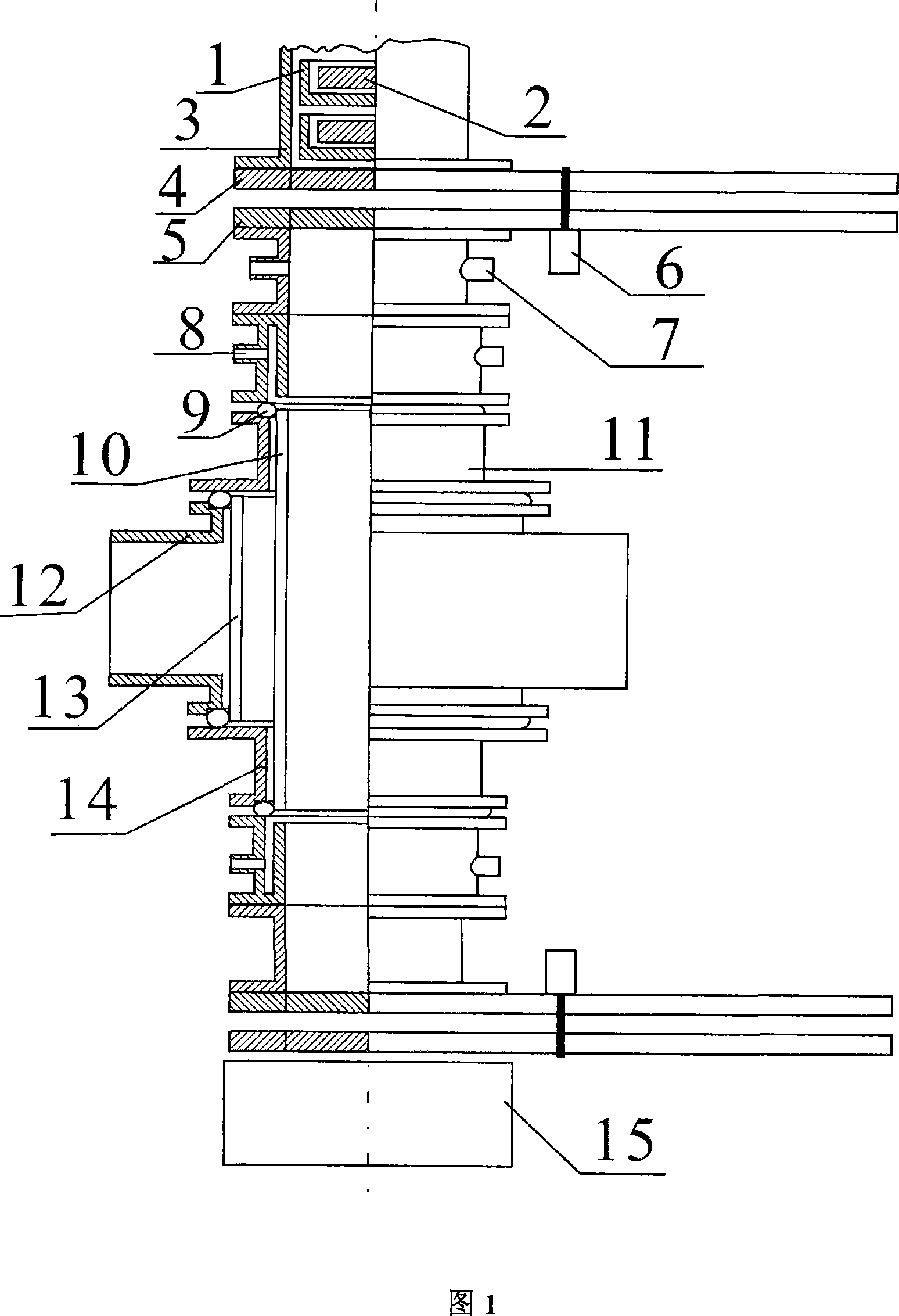

Device for continuously sintering material product by microwave and realization thereof

A sintered material and microwave technology, which is applied to the device and realization field of microwave continuous sintered material products, can solve problems such as continuous sintering, and achieve the effects of fast sintering rate, simple structure and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: 200 sccm N is filled in the microwave sintering chamber 2 , Three pieces of diamond-tungsten carbide product slices are placed in a quartz crucible, and the quartz crucible is operated at a microwave power of 2000W for 15 minutes to achieve rapid microwave sintering.

Embodiment 2

[0025] Example 2: 200 sccm N is filled in the microwave sintering cavity 2 A slab of diamond-tungsten carbide product is placed in a quartz crucible, and the quartz crucible can be sintered by microwave under the microwave power of 2000W for 15 minutes.

Embodiment 3

[0026] Example 3: Under air conditions, two medium-thick alumina products were placed in a quartz crucible, and the quartz crucible was operated at a microwave power of 2000W for 15 minutes to achieve rapid microwave sintering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com