Method for extracting unmodified natural collagen from tanning waste leather scrap

A technology of natural collagen and leftovers, which is applied in the field of extracting undenatured natural collagen, can solve the problems of low added value and no biological activity, and achieve unique biocompatibility, low biodegradability and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

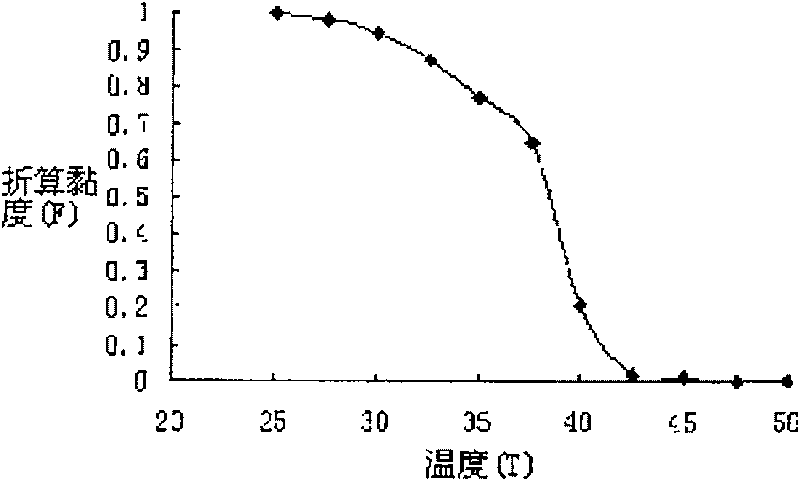

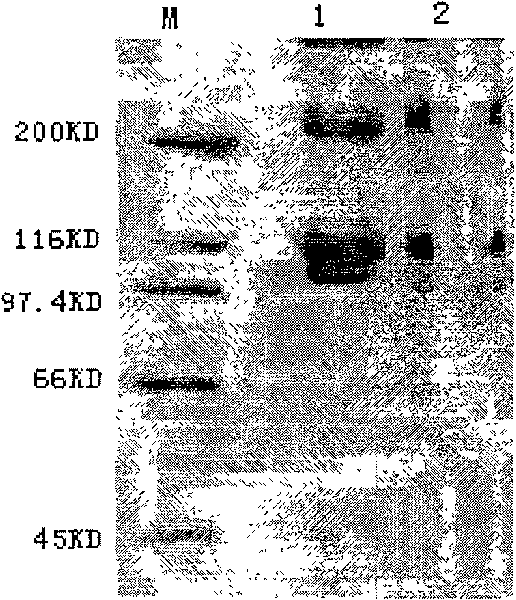

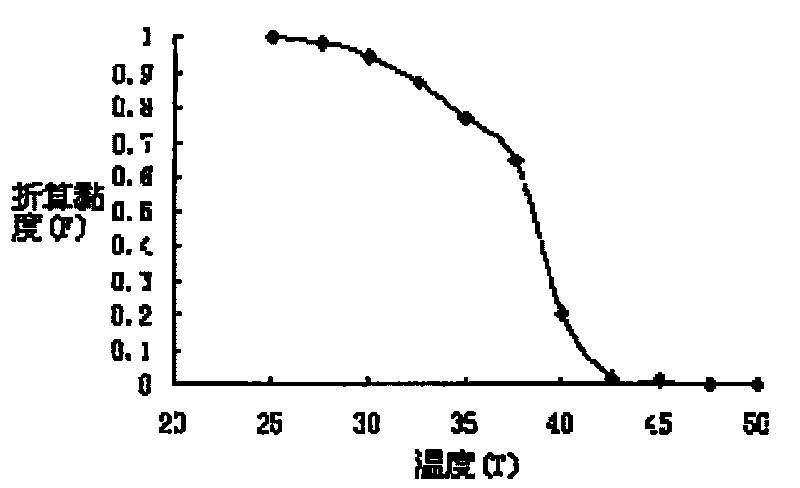

Image

Examples

Embodiment 1

[0027] Embodiment 1: get the leftovers of beef slices ash and alkali skin, mince, get 100g, adjust pH=8 with 2M NaOH solution to make the skin swell for 24 hours, use concentration of 30g / L solution pH=8 H 2 o 2 Bleach for 3 hours, then decalcify with 200g of 0.5M EDTA decalcification solution for 24 hours, fully elutriate with tap water, filter to obtain sediment, adjust pH=2.5 with acid, add 2g of pepsin, and stir at 4-6°C for 24 hours. The filter residue was removed by centrifugation, 0.7M NaCl was added to the supernatant for salting out, and the precipitate was dissolved with 0.5M acetic acid to obtain about 600 g of a 5% cowhide undenatured natural collagen solution.

Embodiment 2

[0028] Embodiment 2: get the leftovers of beef slice ash and alkali skin, mince, get 100g, adjust pH=12 with 2M NaOH solution and make skin swell for 48 hours, be that 60g / L solution pH=10 H with concentration 2 o 2Bleach for 8 hours, then use 250g of 1.0M HCl decalcification solution to decalcify for 48 hours, fully elutriate with tap water, filter to get sediment, adjust pH=3 with acid, add 537 protease 5g, stir at temperature 4-6°C for 48 hours, The filter residue was removed by centrifugation, 2.1M NaCl was added to the supernatant for salting out, and the precipitate was dissolved with 0.5M acetic acid to obtain about 650 g of undenatured natural collagen solution of cowhide with a concentration of 8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com