Method for preparing violet sand ceramics alloy material

A technology of purple sand ceramics and alloy materials, which is applied in the field of preparation of purple sand ceramic alloy materials, can solve the problems of poor compactness and hardness, and achieve the effect of high surface hardness, surface hardness resistance to wear, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples will help the understanding of the present invention, but the present invention is not limited thereto.

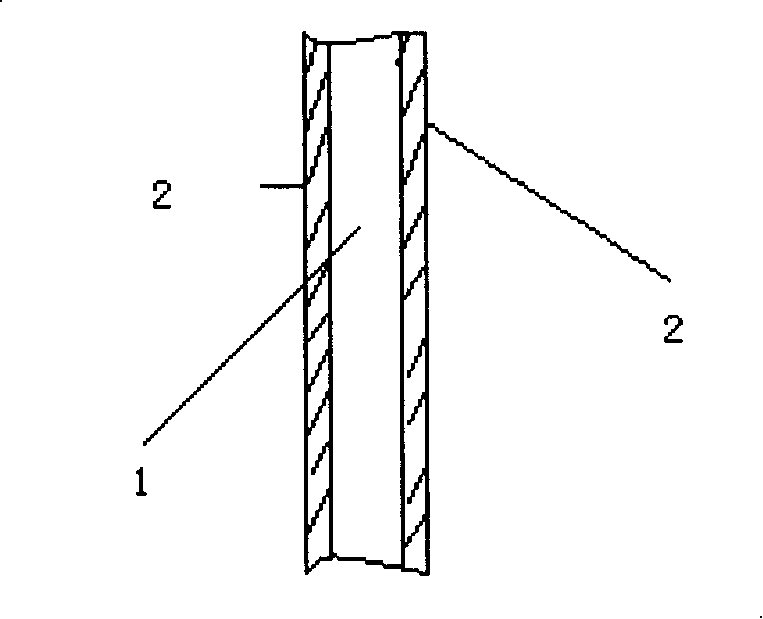

[0027] Such as figure 1 As shown, the purple sand ceramic alloy material of the present invention includes an alloy layer and a purple sand ceramic layer. A purple sand ceramic layer 2 is provided on both surfaces of the aluminum alloy layer 1. The alloy layer is the aluminum alloy layer 1, and the purple sand ceramic layer 2 is The non-sticky purple sand ceramic paint is coated on the alloy surface and then sintered. The thickness is about 20μm.

[0028] Preparation of non-sticky purple sand ceramic coating (room temperature 10℃)

[0029] 1) Preparation of liquid A, first weigh all the components of liquid A, 10.75g polysiloxane, 10.5g silicon dioxide, 17.75g aluminum oxide, 5.25g zinc oxide, 125.5g water, 17.75g Methanol, 16g methylcellulose, 15g ferric oxide, 5g zirconium dioxide, 26.5g titanium dioxide, use water as a solvent to mix thoroughly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com