Metal thin sheet sintering plastic outer parts and its manufacture method

A technology for metal sheets and appearance parts, which is applied in the field of embedding injection molding of products and electroformed sheets, and can solve the problems of uneconomical benefit, increased cost, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

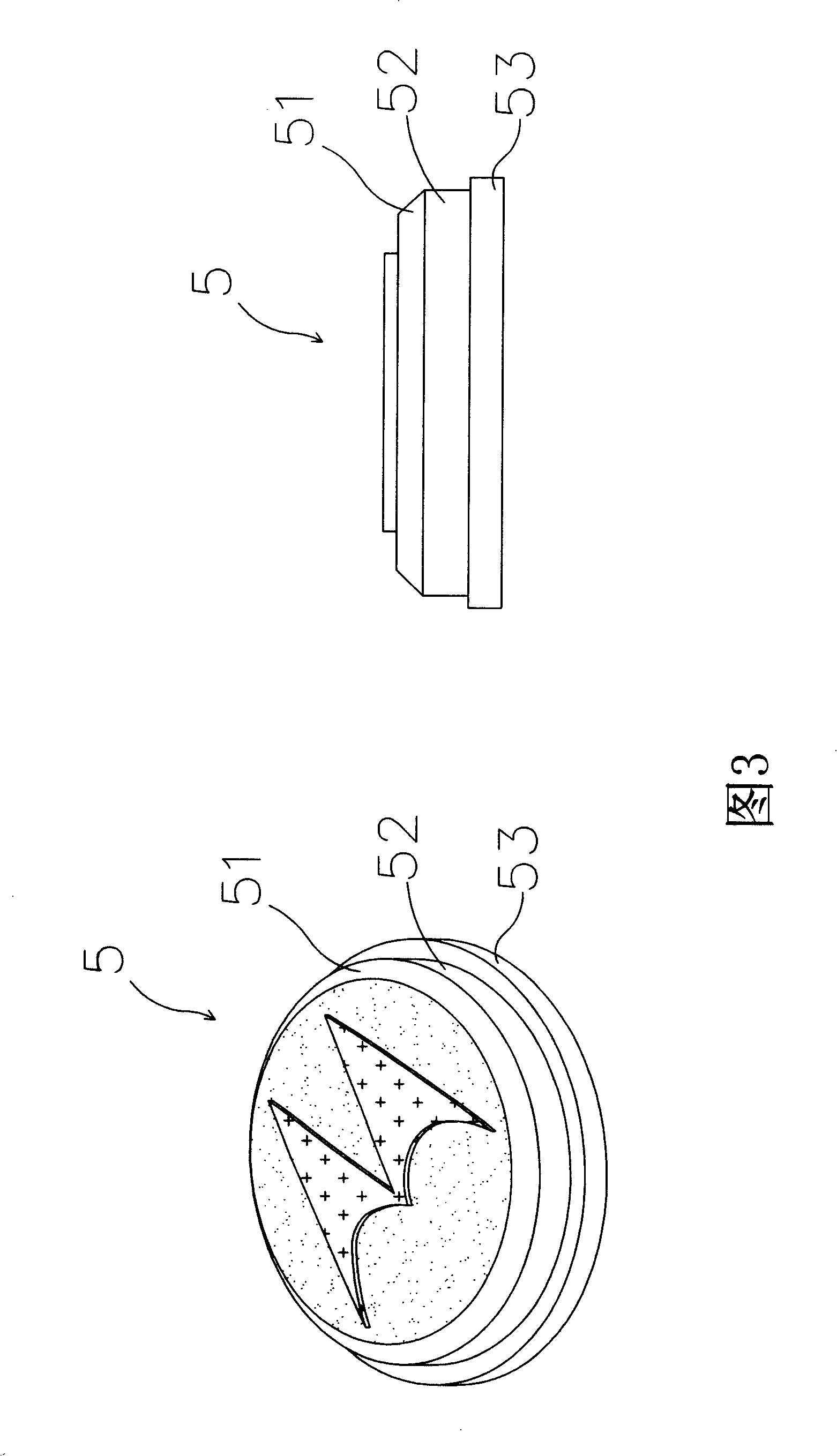

[0030] The invention provides an electroformed sheet embedding injection molding method, which is especially suitable for mass production of appearance parts such as mobile phones, notebook computer casings, buttons, and the like.

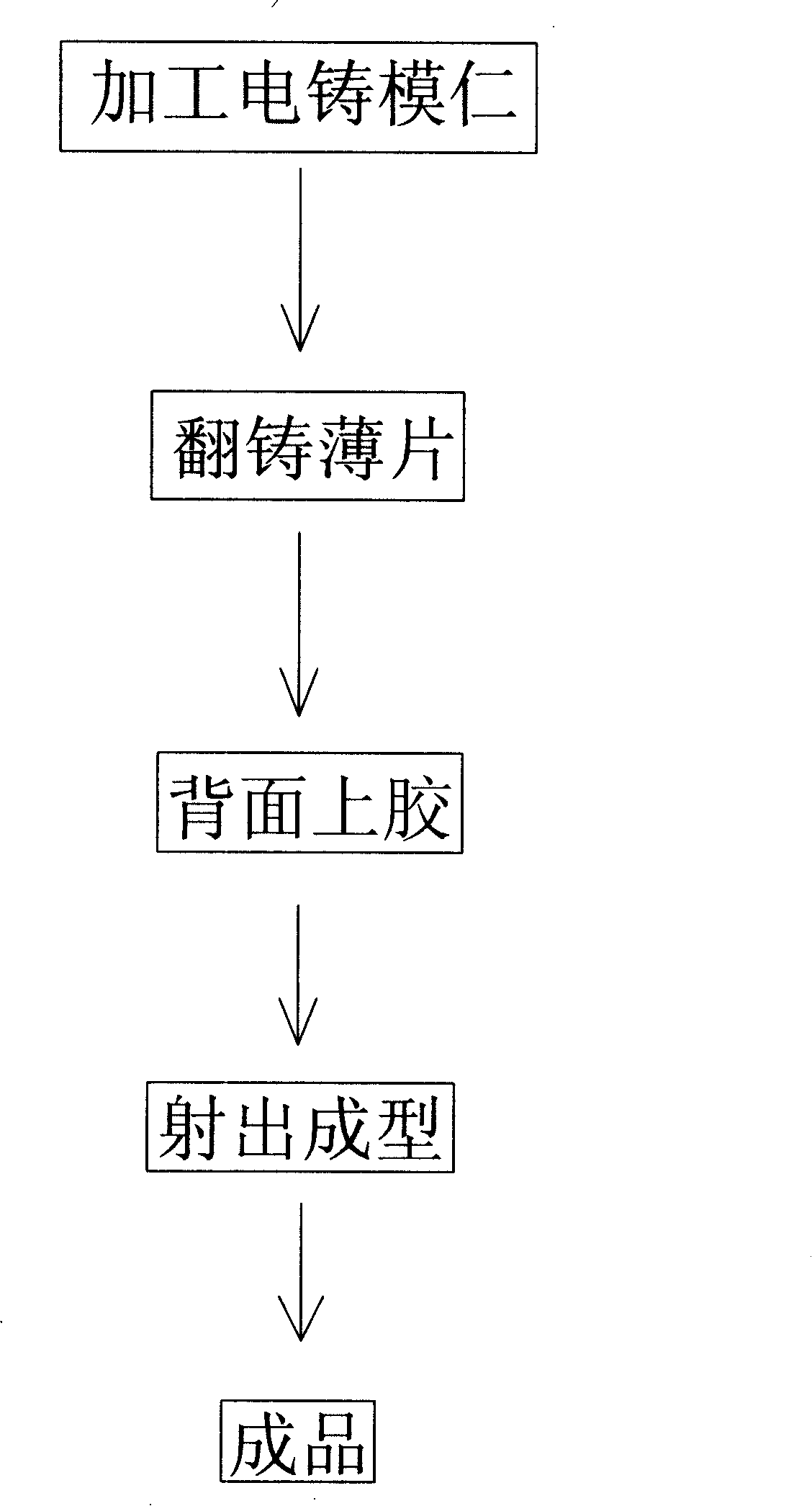

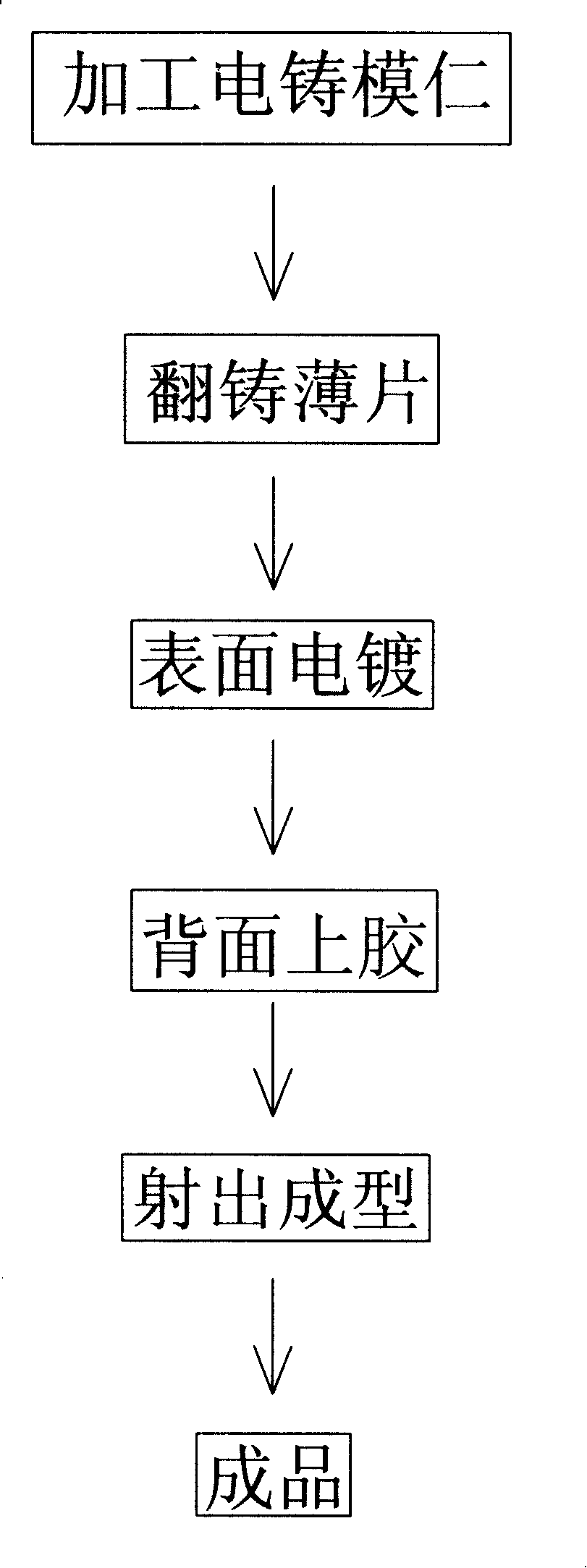

[0031] Please refer to figure 1 Shown is a method flow chart of a preferred embodiment of the present invention; wherein the electroformed sheet embedded injection molding method comprises the following steps:

[0032] (1) Processing of electroforming molds: According to the requirements, various special processing such as lightning, drilling, mirror surface, hair, discharge, etching, etc. are applied to the electroforming molds to make the surface present special visual effects;

[0033] (2) Production of recast sheets: Then recast the sheets and make the electroformed sheets into semi-finished appearance parts, and its thickness is in the range of 0.01-2mm, preferably 0.06-0.1mm;

[0034] (3) Glue on the back: Glue the back of the semi-finished ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com