Vibration-resisting type pointer type SF6 gas density relay

A gas density and relay technology, applied in circuits, electrical switches, electrical components, etc., can solve the problems of micro switch operating arm swing, insufficient strength, and small working stroke of the operating arm, so as to prevent the micro switch from being stuck or detached. , Not easy to deform, and ensure the effect of reliable system work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

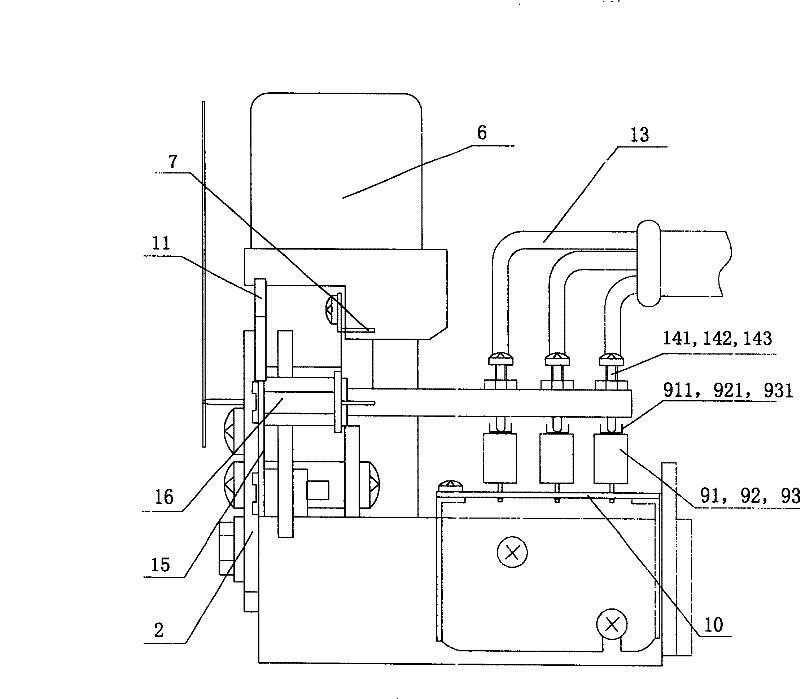

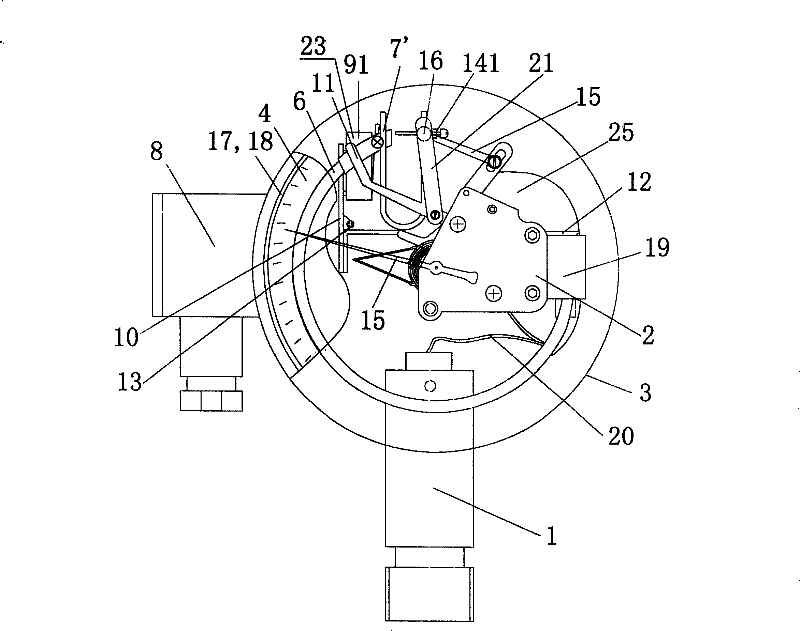

[0049] There can be 1 pair, 2 pairs, 3 pairs or 4 pairs of microswitches and the adjusting rods corresponding thereto, and the present embodiment is 3 pairs.

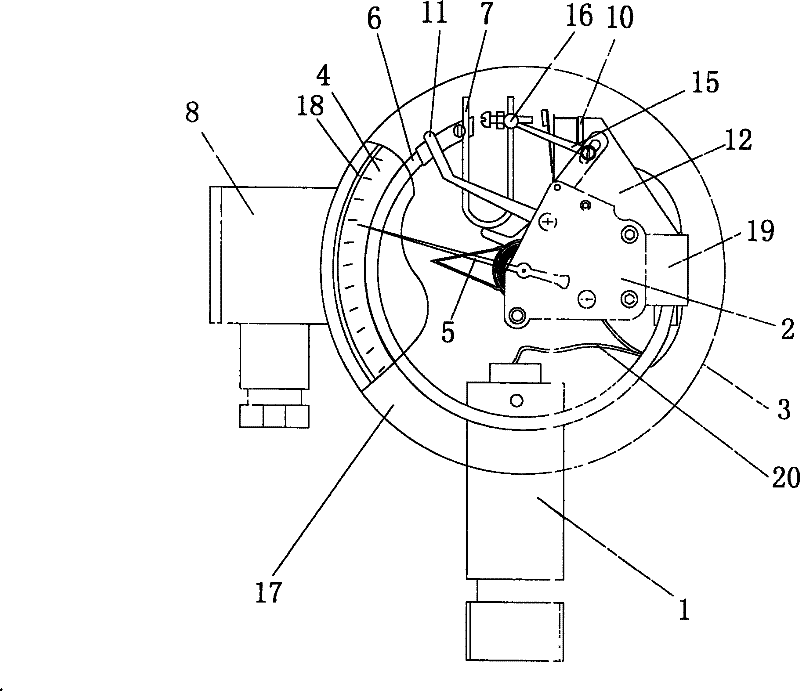

[0050] see Figure 3-4 , the invention anti-vibration pointer SF 6 The gas density relay is mainly composed of connector 1, movement 2, case 3, dial 4, pointer 5, Bourdon tube 6, wide temperature compensation sheet 7' (width 5.5-18mm), terminal block 8, and three micro switches 91, 92, 93, printed circuit board 10, positioning plate 11, fixed plate 12, electric wire 13, three adjustment rods 141, 142, 143, connecting rod 15, beam 16, watch glass 17, cover ring 18, two Baffle plate 21,22, base 19, pipe 20, micro switch strengthening mechanism 23, end seat 24 etc. are formed. Wherein, the joint 1 is fixed on the watch case 3 , and the movement 2 is fixed on the base 19 . One end of the Bourdon tube 6 is welded on the base 19 and communicated with it, the other end is connected to one end of the wide temperature compens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com