Metal-insulator-metal capacitor and its manufacture process

A technology of metal capacitors and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc., can solve problems affecting the film deposition process, etc., and achieve the solution of reaction residues, excellent structure, and optimized manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention relates to the technical field of semiconductor integrated circuit manufacturing, in particular to a method for forming a MIM capacitor in a semiconductor device and the MIM capacitor formed by the method. It should be noted here that the embodiments provided in this specification are used to illustrate various features of the present invention, and are only used for convenience of description by using specific compositions and structures, and are not intended to limit the present invention.

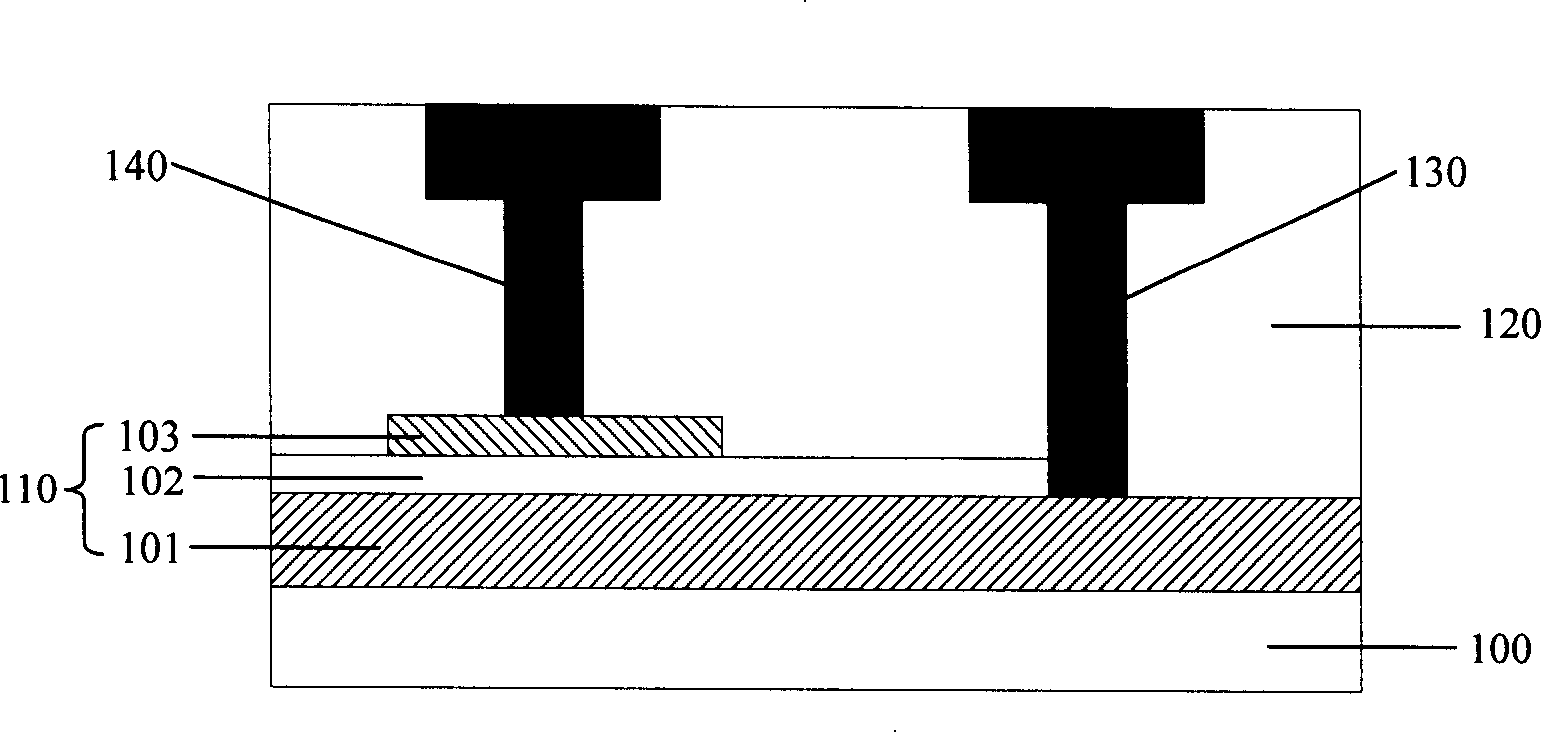

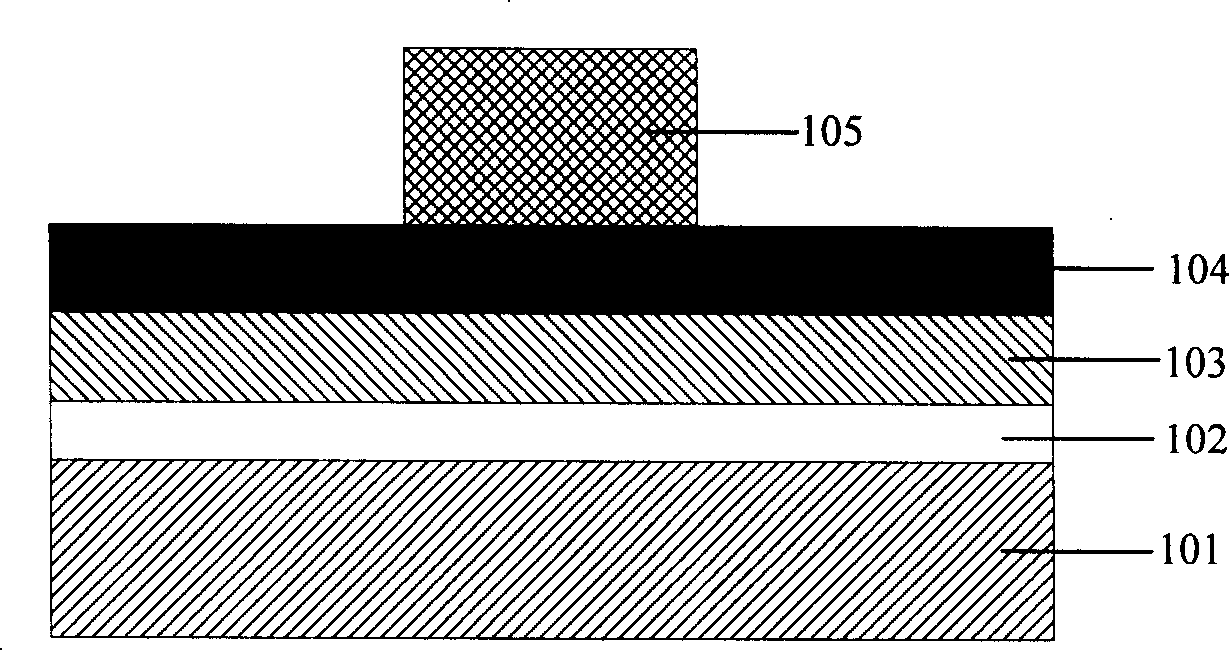

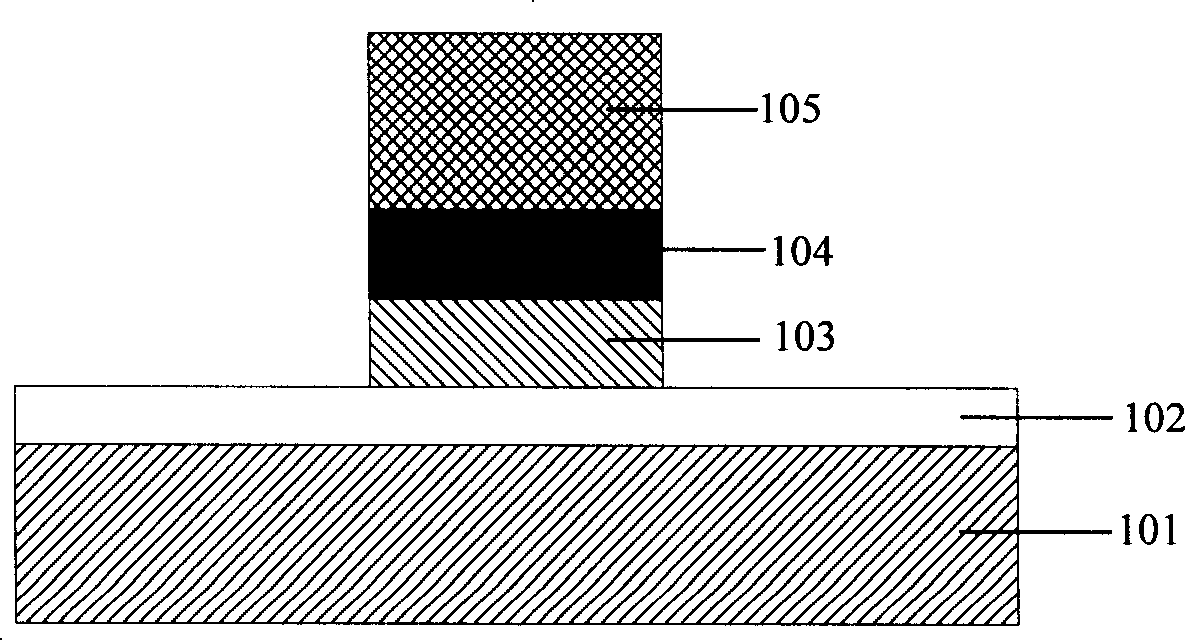

[0029] The manufacturing method of the metal-insulator-metal capacitor of the present invention adopts the method of single damascene to form the upper electrode of the MIM capacitor, that is, adopts the way of filling, and after forming the lower electrode metal layer and the dielectric layer, a layer of intermetallic layer is formed on the surface of the dielectric layer. dielectric layer (IMD), and use the photoresist as a mask to define the position of the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com