Vertical type bipolar transistor manufacture method and vertical type bipolar transistor

A technology of bipolar transistors and manufacturing processes, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of high manufacturing cost, complicated process, and complicated manufacturing technology, and achieve lower precision requirements, lower costs, The effect of process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

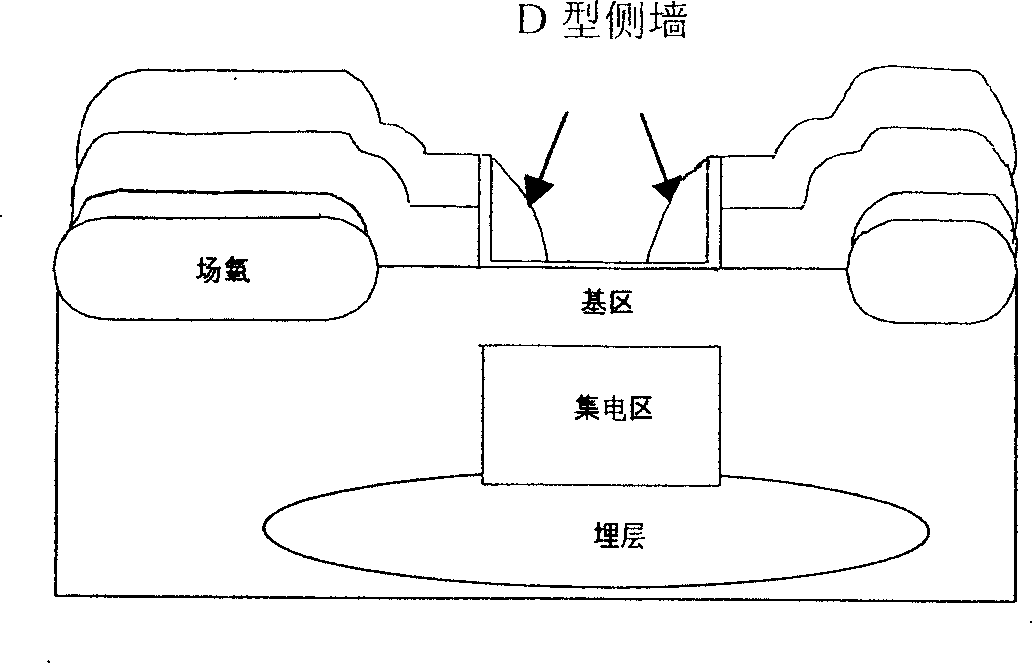

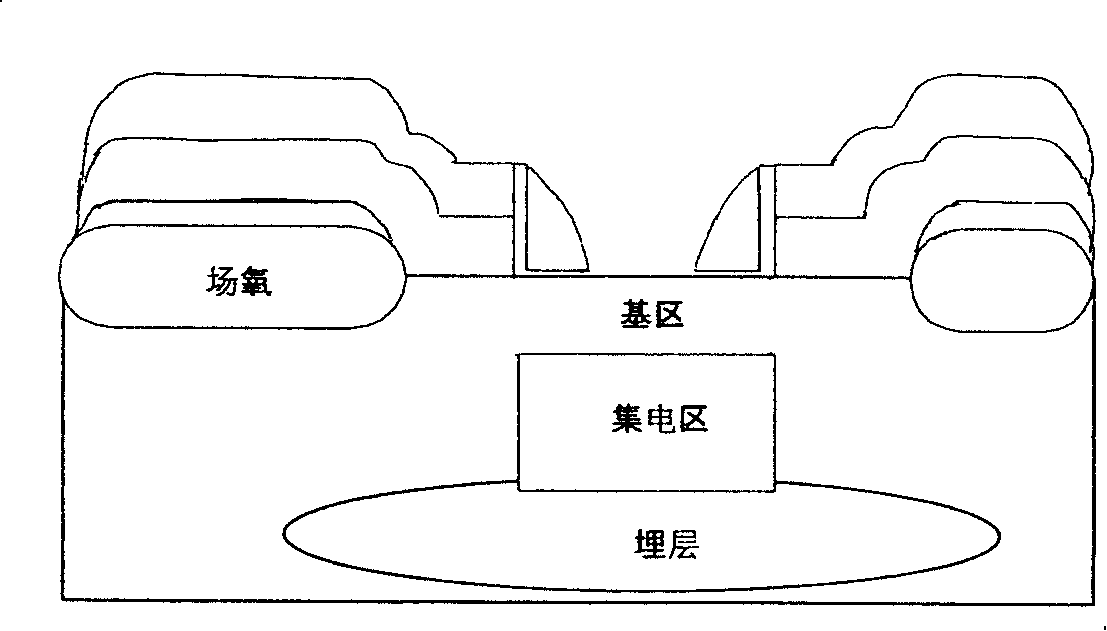

[0012] The preparation method of the vertical bipolar transistor described in the present invention adopts a D-shaped side wall structure and combines a self-alignment process to form the emitter in a small-sized vertical bipolar transistor. The D-shaped side wall is also used to isolate the external base and emitter. The specific implementation process is as follows:

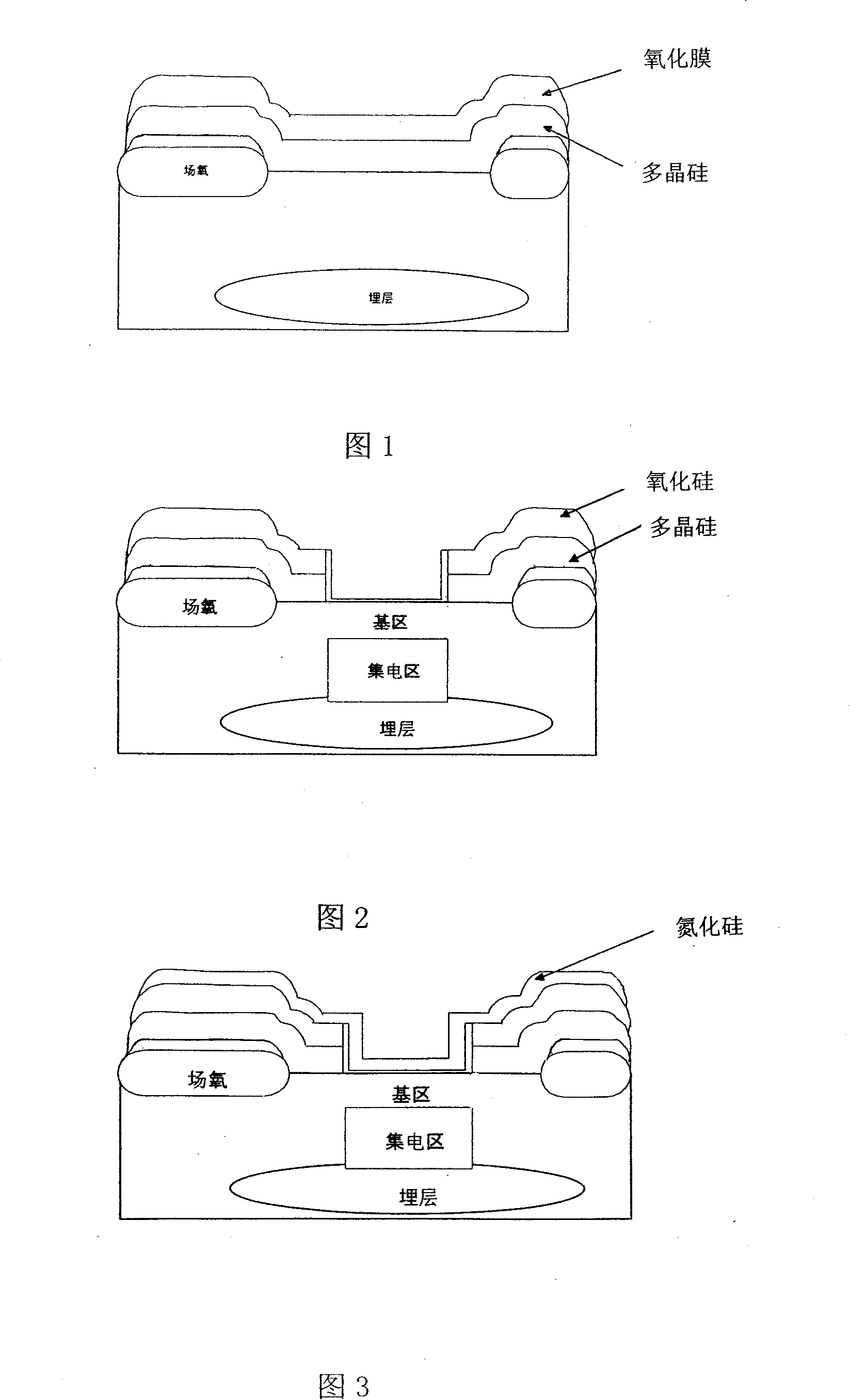

[0013] First, a layer of polysilicon is deposited on the P-type silicon substrate, and a thicker (about 2000 Angstroms) oxide film is deposited on the polysilicon layer (see FIG. 1 ). The deposition method can be the common chemical vapor deposition, or other methods to form the polysilicon layer. The specific methods for forming the polysilicon layer, the nitride film layer, etc. described in the following steps of the present invention can be realized by various methods known in the prior art.

[0014] The ion implantation region is formed by photolithography and etching, and the ion implantation region is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com