Spinning moment transferring written magnetic random access memory and its manufacture method

一种铁磁性、纳米磁性的技术,应用在磁性随机存取存储领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

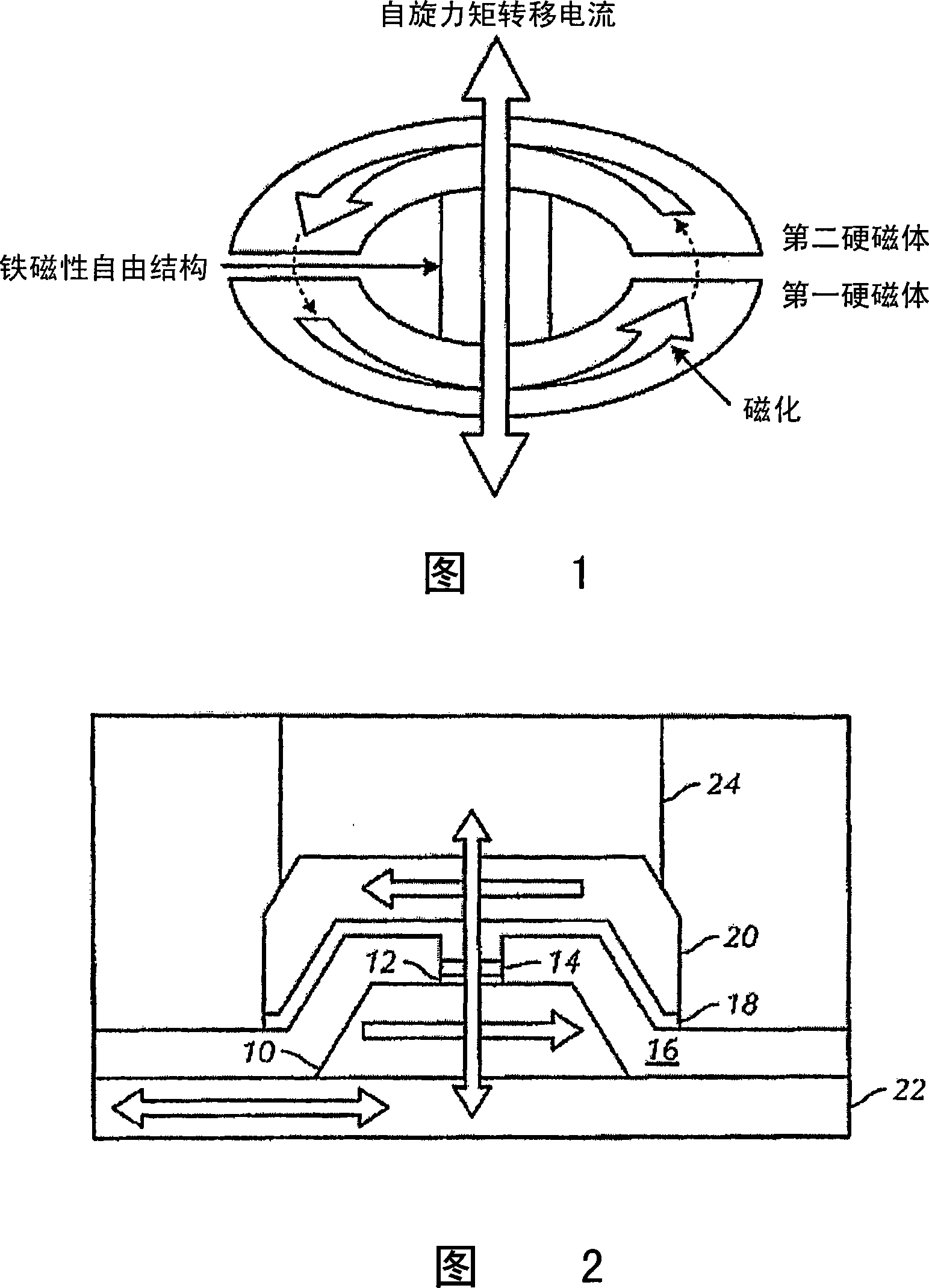

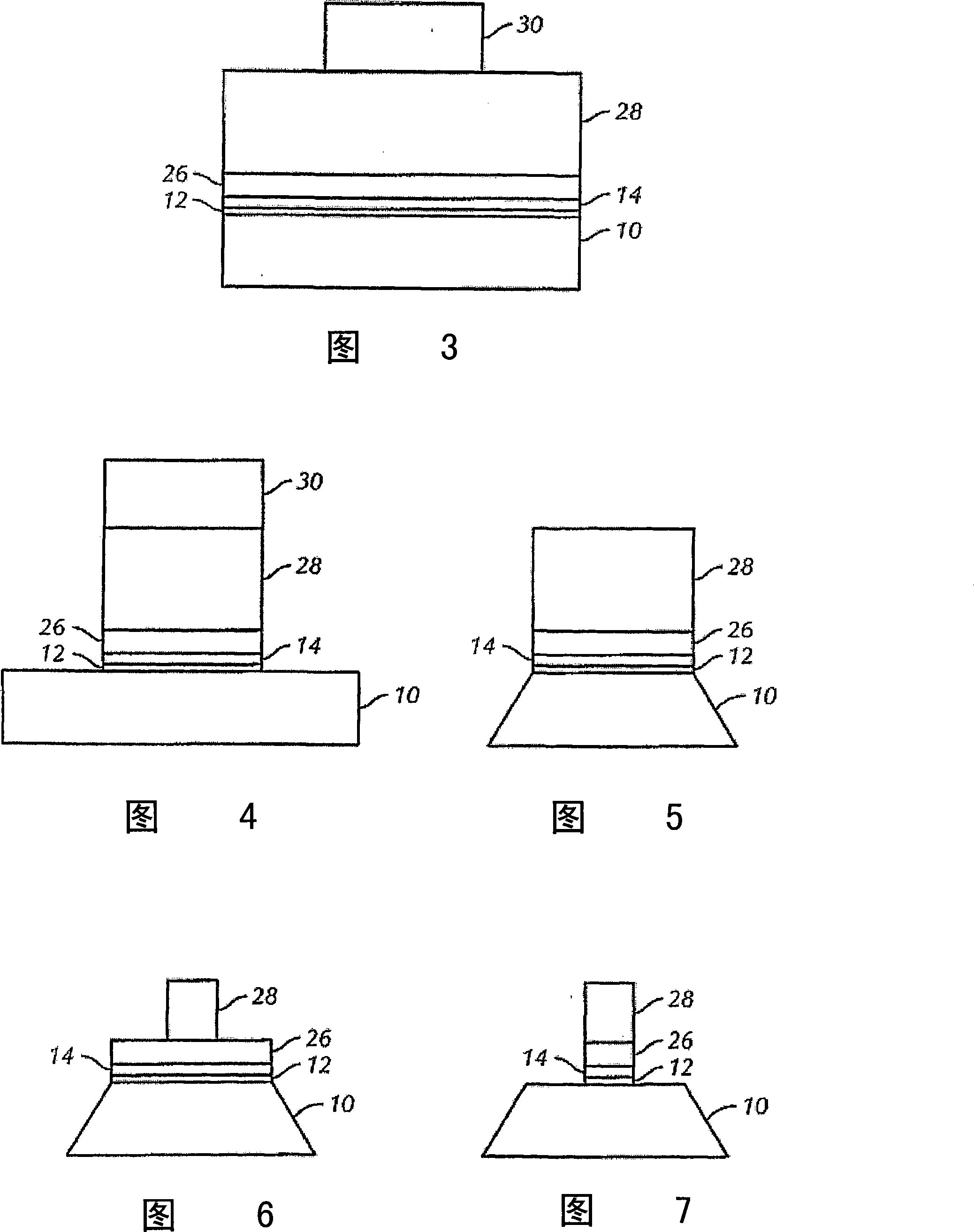

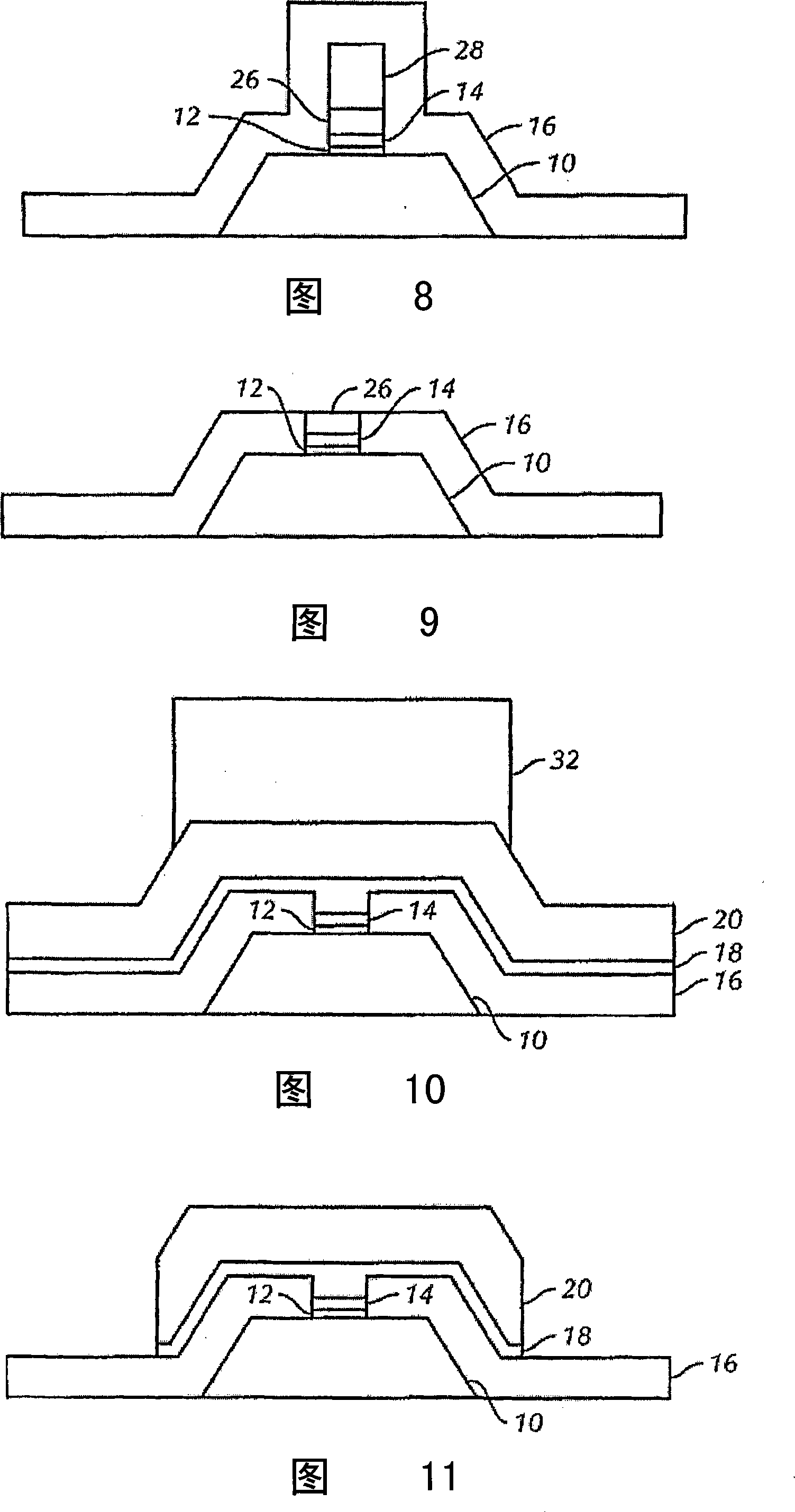

[0025] FIG. 1 shows a cross-section of the basic structure of an embodiment of the invention. During a write operation, a current pulse is passed from a hard magnet through the MRAM element structure, the ferromagnetic free structure, and the second hard magnet. current densities in the range of about 10 5 A / cm 2 to about 10 7 A / cm 2 , and the pulse duration ranges from about 0.1ns to 100ns.

[0026] Unlike the prior art where each layer is flat and has the same width as the other layers, Figure 1 shows that the two hard magnets are much larger relative to the ferromagnetic free structure. This enablement utilizes low current densities for device programming. The current density required to change the magnetization direction follows the equation:

[0027] J=J c0 [1-(KT / E)ln(τ 0 / τ p )], where E=M s VH k / 2

[0028] J c0 , K (Boltzmann's constant) and τ 0 is a constant, τ p (pulse duration), T (temperature), M s (saturation magnetization), V (element volume), an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com