Injection molding method for thermoplastic resin

A thermoplastic resin, injection molding technology, used in the field of injection molding, can solve the problems of uneven shrinkage, carbon dioxide can not evenly penetrate the surface layer, increase molding cost, etc., and achieve improved reproduction and gloss, excellent reproduction and gloss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

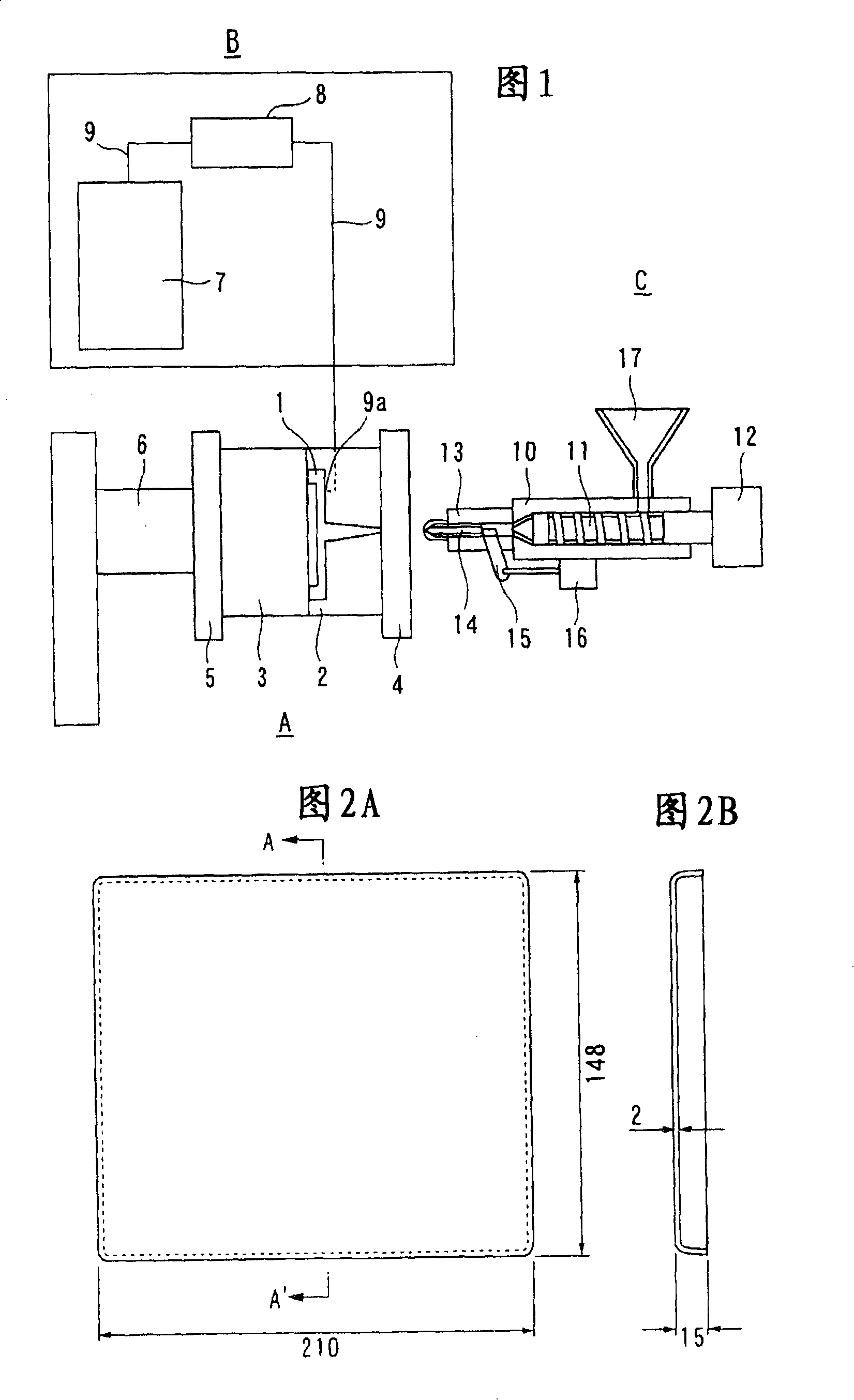

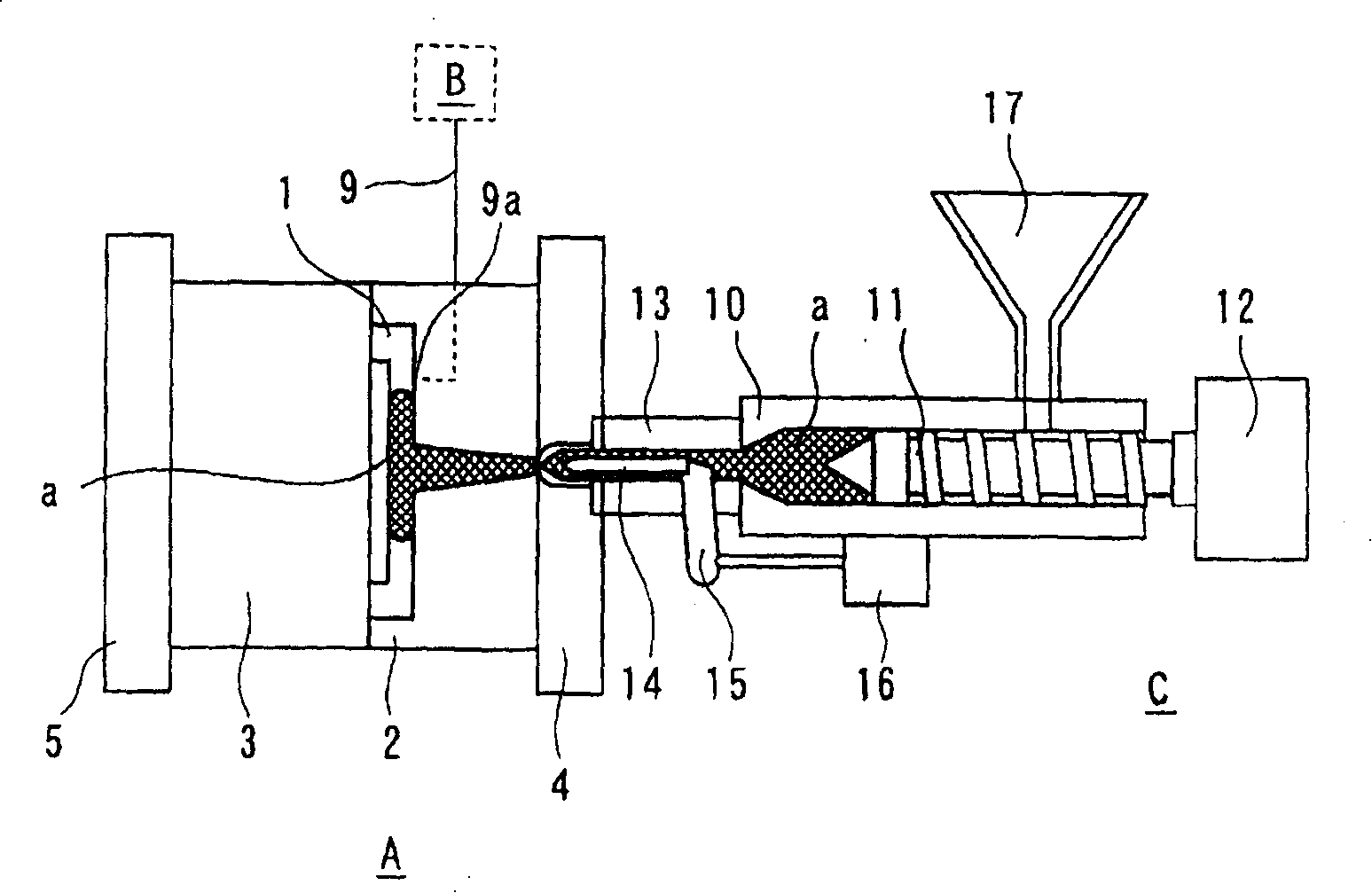

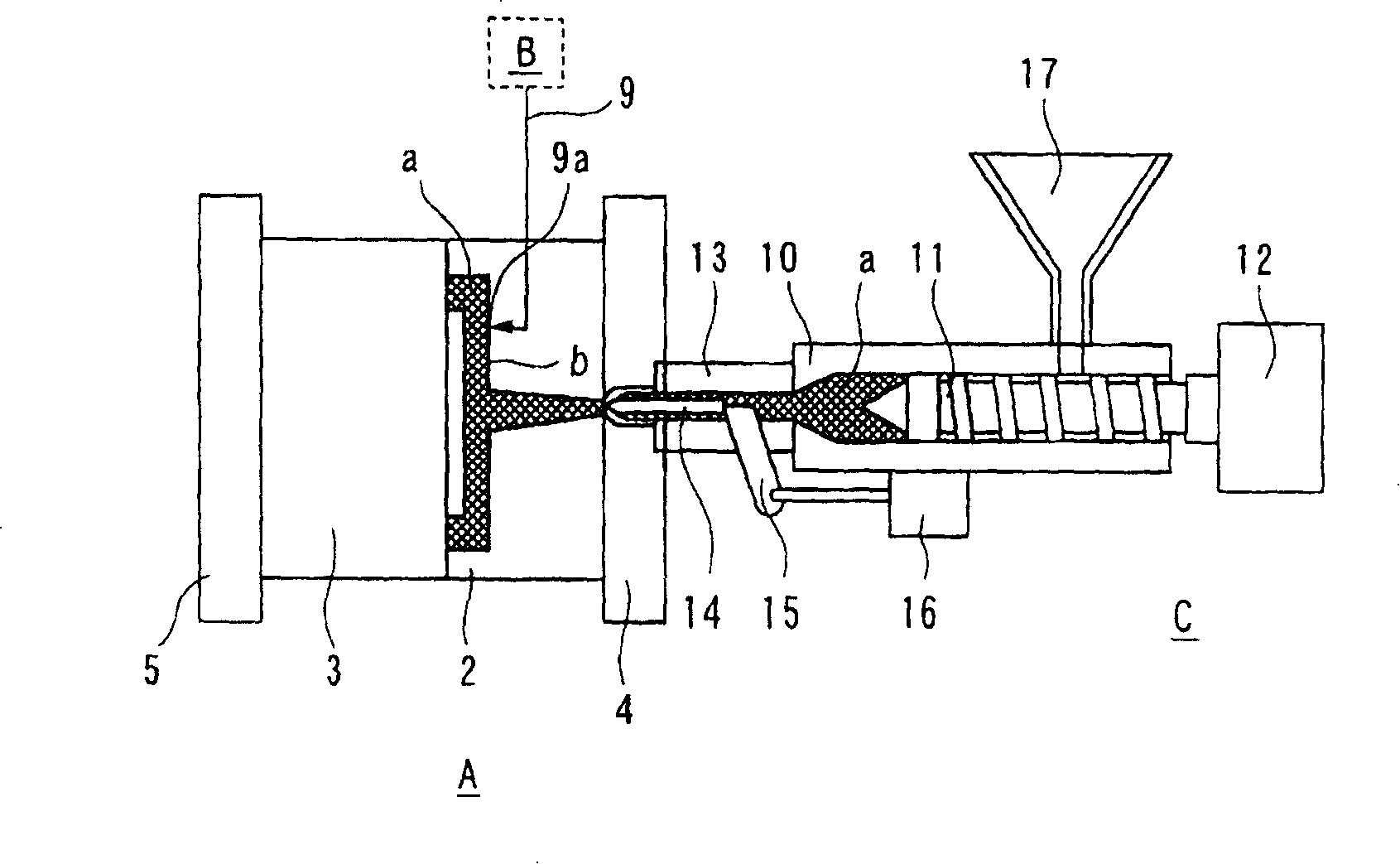

[0035] Fig. 1 is an overall view showing a molding device A, a carbon dioxide injection device B and a resin filling device C in an injection molding machine for carrying out the present invention. Reference numeral 1 is a mold cavity formed by clamping the fixed side mold 2 and the movable side mold 3 in the injection molding device A, 4 is a fixed side mold plate, 5 is a movable side mold plate, and 6 is a mold plate position adjustment device.

[0036] In the carbon dioxide injection device B, 7 is a high-pressure carbon dioxide generator that generates high pressure, 8 is a carbon dioxide injection unit, and 9 is a piping that connects the high-pressure carbon dioxide generator 7 and the carbon dioxide injection unit 8 and the injection unit 8 and the mold cavity 1 The injection ports 9a are connected, and carbon dioxide can be injected into the visible surface side of the cavity 1 from the piping 9 .

[0037] In the resin filling device C, 10 is a cylinder, 11 is a screw in...

Embodiment 2

[0044] This embodiment 2 corresponds to the invention described in claim 3. In embodiment 2, after the filling process is completed, when the resin discharge port at the tip of the nozzle part 13 is closed while the stop pin 14 is kept advancing, the screw 11 is advanced, After increasing the resin pressure on the tip side of the screw 11 inside the barrel 10 and maintaining it, as Figure 5 As shown, by driving the shut-off operation control device 16, the discharge port of the nozzle part 13 is opened, and the molten resin a maintained at high pressure flows into the cavity 1 of the mold at one stroke, and the same as in the first embodiment except that take shape. As a result, a good molded article having a glossiness of 85, excellent reproducibility, and 100% of the evaluated area was reproduced was obtained.

Embodiment 3

[0050] Present embodiment 3 corresponds to the invention described in technical solution 4. In embodiment 1, after the filling process of molten resin is completed, start from the position of driving the flow-cutting operation control device 16 to stop and hold the screw rod 11, as Figure 6 As shown, the mold plate 5 was retracted by 0.01mm, the movable mold 3 was slightly opened 1a, the resin pressure in the cavity 1 was lowered, and carbon dioxide was injected, and molding was carried out in the same manner. As a result, the glossiness of the obtained molded article was 80, and a good molded article excellent in reproducibility and free from partial reproducibility defects could be obtained. In the evaluation area on the visible surface side, the reproduction of the area ratio area of 100% can be improved.

[0051] In addition, the examples 1 to 3 are described by taking only carbon dioxide injected into the mold cavity 1 as an example, but it is also possible to inject m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com