Method for producing beta crystal system anhydrous aztreonam

A technology of aztreonam and β crystal form, which is applied in the production field of β crystal form anhydrous aztreonam, can solve the problems of large amount of absolute ethanol, low industrial production efficiency, and high ethanol content of β crystal form aztreonam, Achieve the effects of reducing ethanol content, improving production efficiency and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

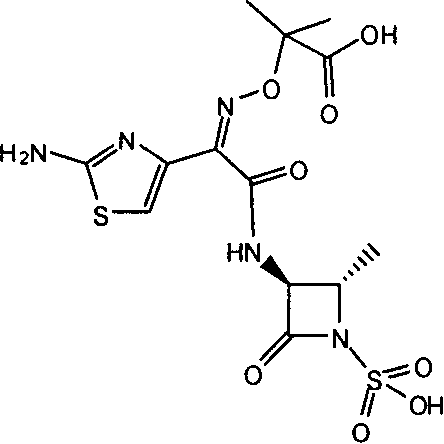

Image

Examples

reference example 1

[0026] At 8-10°C, add α-crystalline aztreonam (40g) into pre-cooled absolute ethanol (2400ml), stir for 30 minutes to obtain a transparent solution, keep at 8-10°C, add activated carbon (1g) and stir the above solution for 15 minutes, the resulting suspension was filtered, and the filter cake was washed with ethanol (50ml). Afterwards, the filtrate was slowly heated to 50-55°C within 2 hours under stirring, and crystals were precipitated as β crystal form aztreonam. The liquid was cooled to 15-20°C, stirred for 1 hour and filtered again, and the resulting crystalline product was dried in vacuo to obtain 28 g of product. Infrared spectra and powder X-ray diffraction showed that the crystal form of the product was consistent with that of the standard product (β crystal form aztreonam). Gas chromatographic analysis showed that the ethanol content was 2.3%.

Embodiment 1

[0028] At 10-15°C, add α crystal form aztreonam (40g) into pre-cooled absolute ethanol and acetone (3∶1) (1000ml), stirred for 5 minutes to obtain a transparent solution, kept at 10-15°C, added activated carbon (1g) and stirred the above solution for 15 minutes, filtered the resulting suspension, washed the filter cake with acetone (50ml), and then stirred The lower filtrate was slowly heated to 35-40° C. within 2 hours, and the precipitated crystals were β crystal form aztreonam. The suspension was cooled to 15-20°C, stirred for 1 hour and filtered again, and the resulting crystalline product was dried in vacuo to yield 33.5 g of product. Infrared spectra and powder X-ray diffraction showed that the crystal form of the product was consistent with that of the standard product (β crystal form aztreonam). Gas chromatographic analysis showed that the ethanol content was 0.9%.

Embodiment 2

[0030] At 10-15°C, add α crystal form aztreonam (40g) into pre-cooled absolute ethanol and acetone (3∶1) (1000ml), stirred for 5 minutes to obtain a transparent solution, kept at 10-15°C, added activated carbon (1g) and stirred the above solution for 15 minutes, filtered the resulting suspension, washed the filter cake with acetone (50ml), and filtered out After the solution was vigorously stirred for 40 minutes, white crystals began to precipitate. Continue to stir for 1 hour, and a large amount of crystals precipitated. Under stirring, the solution was slowly heated to 35-40°C within 30 minutes to completely precipitate the crystals. The precipitated crystals were β crystal form aztreonam . The suspension was cooled to 15-20°C, stirred for 1 hour and filtered again, and the resulting crystalline product was dried in vacuo to yield 32 g of product. Gas chromatographic analysis showed that the ethanol content was 0.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com