Vibration isolation system

A vibration isolation system and powertrain technology, applied in the direction of shock absorber, shock absorber-spring combination, mechanical equipment, etc., can solve the problems of high-frequency dynamic hardening, short service life, etc., and achieve good manufacturing process and structure Lightweight, solve the effect of high-frequency dynamic hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

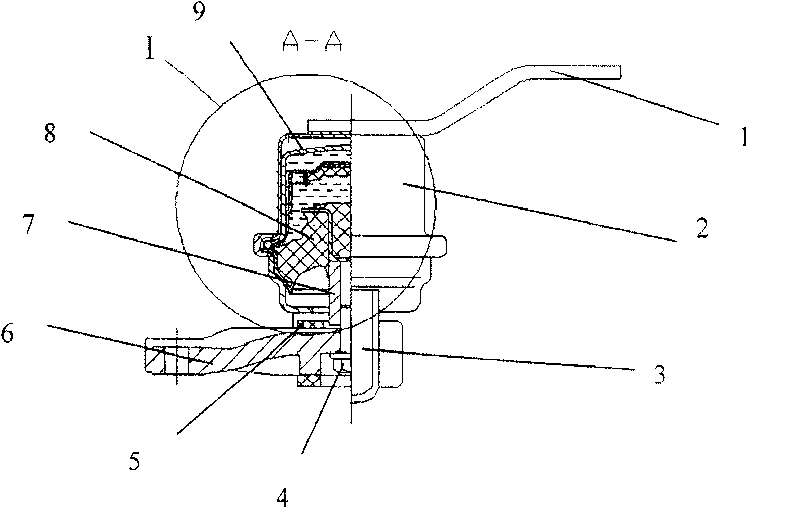

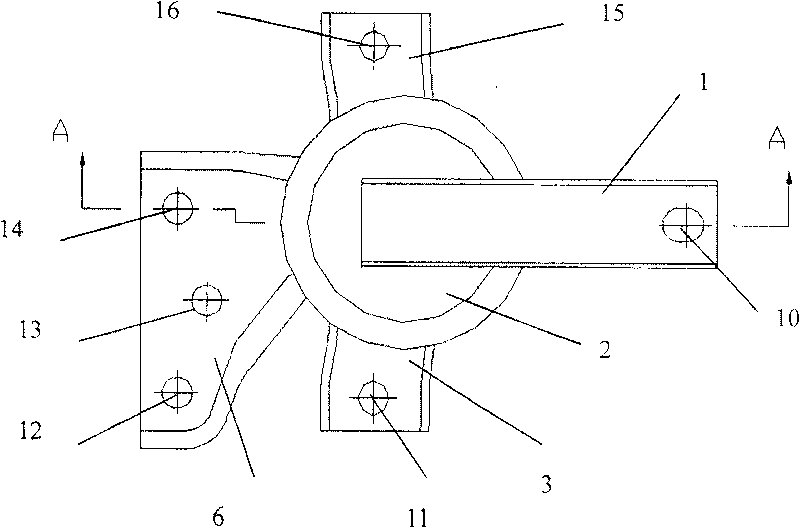

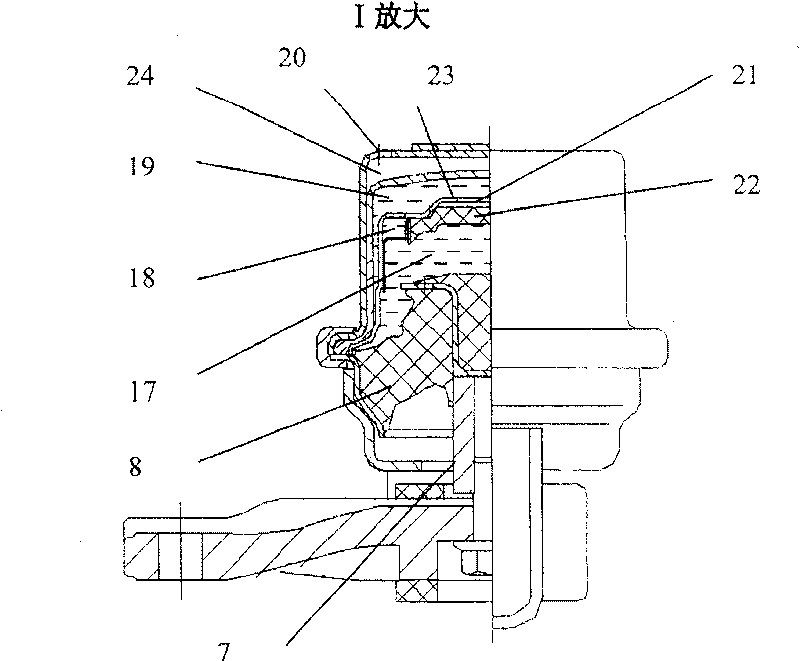

[0012] exist figure 1 , 2 and 3, a powertrain vibration isolation system, which is a liquid resistance type vibration isolation system. Including outer casing 2, right bracket 1, front bracket 3, left bracket 6, rear bracket 15, buffer pad 5, bolt 4, connecting rod 7, rubber body 8, inner casing 9, and the outer casing 2 is connected with right Bracket 1, front bracket 3, rear bracket 15; A buffer pad 5 is arranged between the left bracket 6 and the housing 2; it is characterized in that: the outer housing 2 is connected with the inner housing 9, and a cavity 24 is surrounded in the middle; 2 There is a vent hole 20, and the cavity 24 communicates with the atmosphere through the vent hole 20; a rubber body 8 is vulcanized on the inner shell 9, and a connecting rod 7 is implanted on the rubber body 8, and the connecting rod 7 is connected with the left bracket 6 by a bolt 4 The area surrounded by the rubber body 8 and the inner casing 9 contains damping fluid and a decoupling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com