Production method for RFID etching aluminum antenna

A manufacturing method and a technology of etching aluminum, which are applied to antennas, antenna parts, and chemical/electrolytic methods to remove conductive materials, etc., can solve problems such as poor folding resistance, short service life, and poor reliability, and achieve application promotion. The effect of overcoming difficult factors and easy ink removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

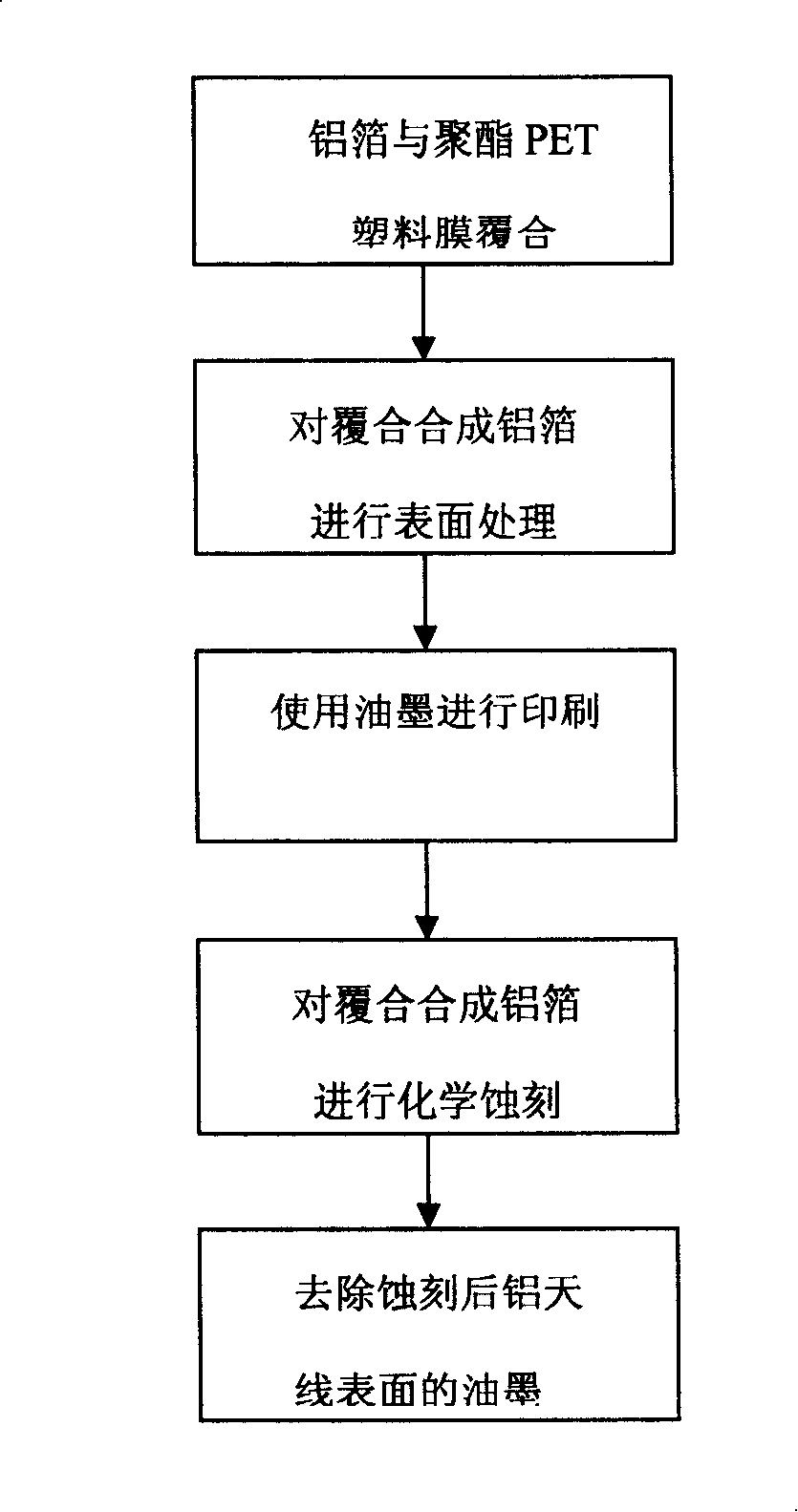

[0026] Such as figure 1 Shown, a kind of manufacturing method of RFID etching aluminum antenna, comprises the following steps: 1. Aluminum foil is laminated with polyester PET plastic film; 2. Use cleaning solution to carry out surface treatment to composite aluminum foil; 3. Use ink to print ; 4. Carrying out chemical etching on the laminated synthetic aluminum foil; 5. Removing the ink on the surface of the etched aluminum antenna.

[0027] The basic material of the antenna is aluminum foil. The impurity content, material, thickness, and surface state of the aluminum foil will directly affect the quality of the product. Therefore, in order to achieve the performance index of the antenna, the aluminum content of the aluminum foil described in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com