Heating plant with radiant tubes

A technology of heating equipment and radiant tubes, applied in lighting and heating equipment, heating methods, mechanical equipment, etc., can solve problems such as impossible universal method, not allowed to control the flow of carrier fluid, equipment that cannot work under ideal conditions and maximum efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

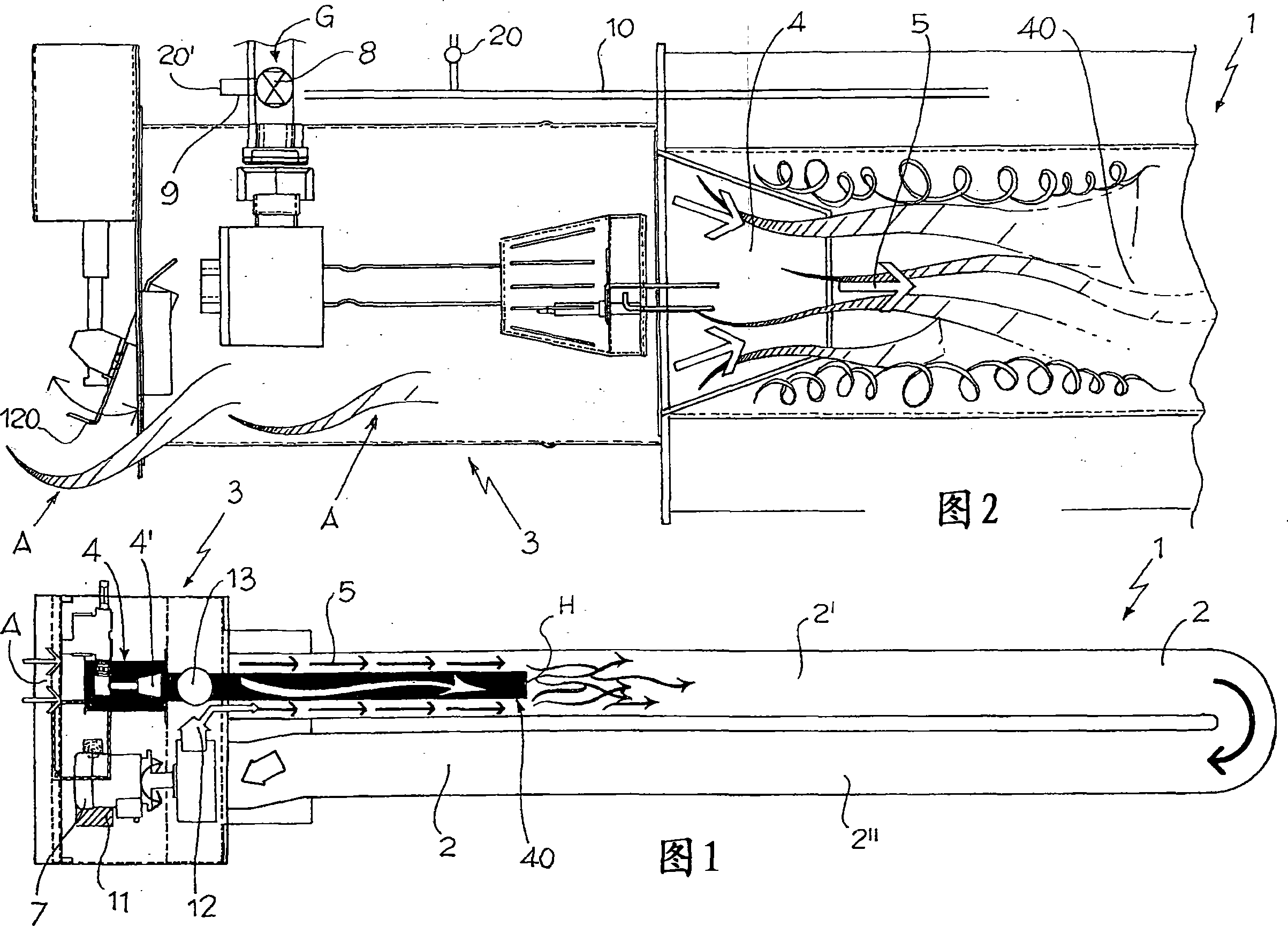

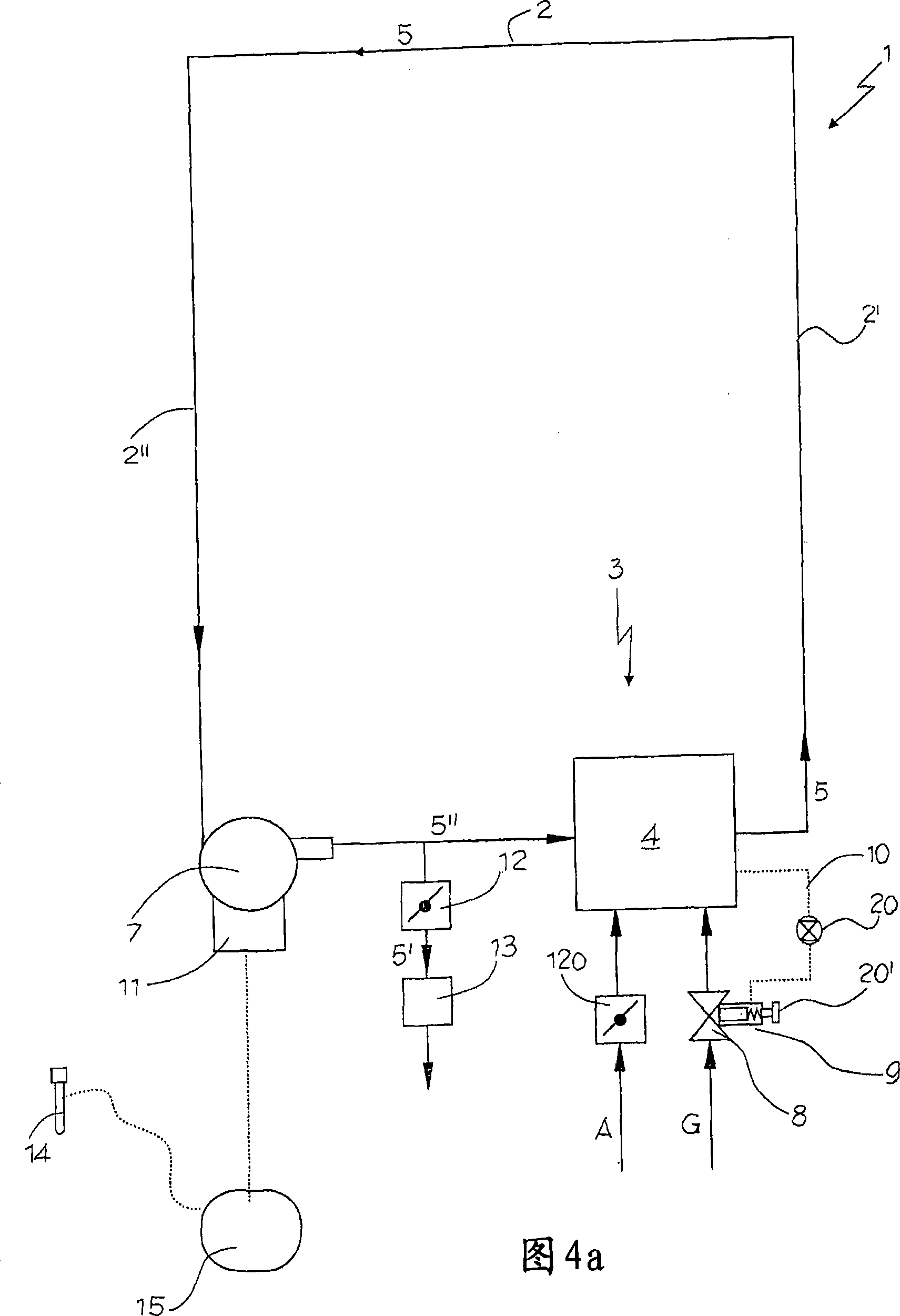

[0069] According to one embodiment, the regulating device comprises a flow regulating device of the carrier fluid 5 .

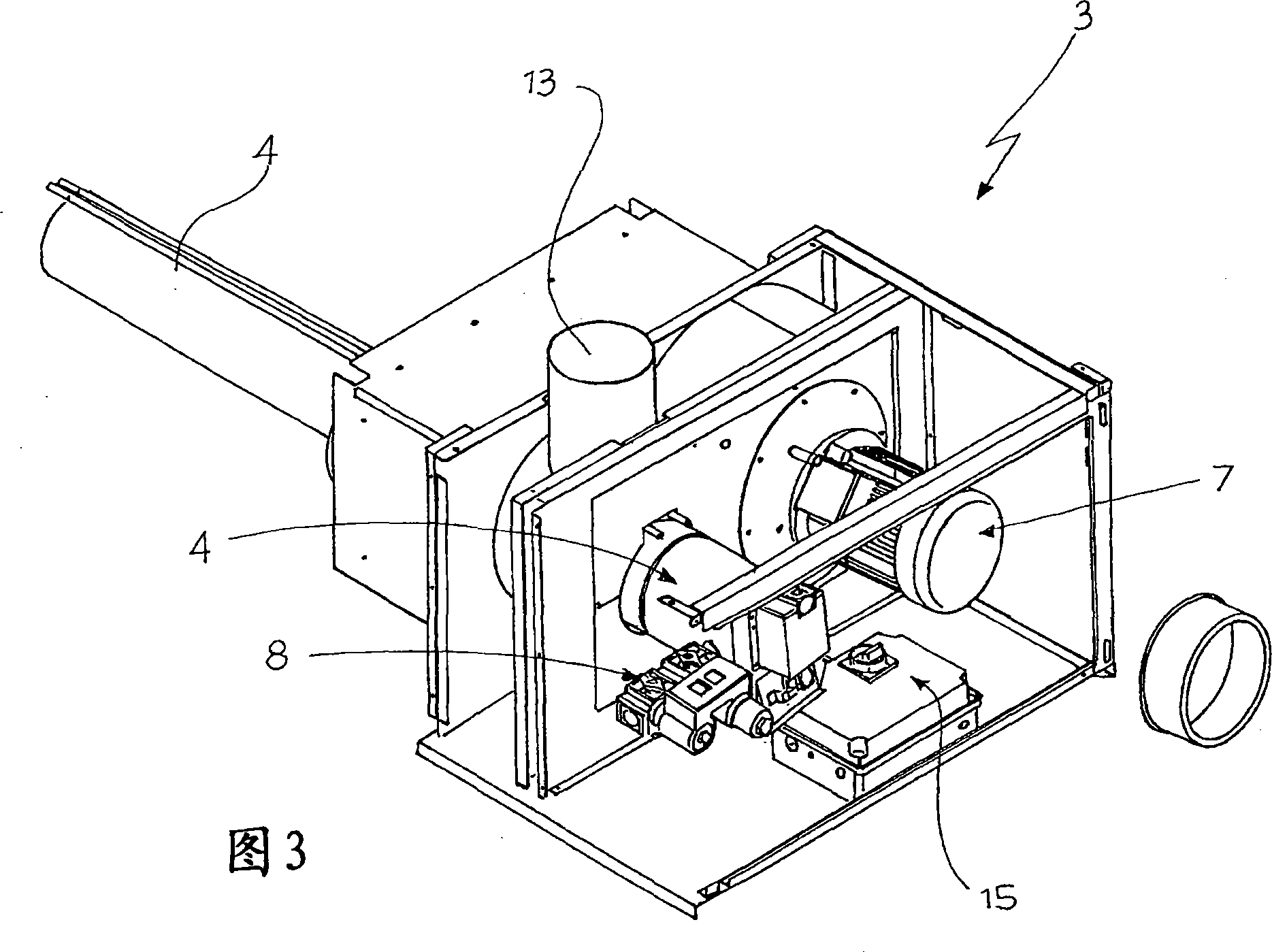

[0070] According to the embodiment of the present invention described in FIG. 4 a , such means for adjusting the flow rate of the carrier fluid 5 may include means for adjusting the speed of the fan 7 , such as converters 11 or other types of actuators.

[0071] According to the embodiment of the invention described in Figures 4b, 4c, such a flow regulating device for the carrier fluid 5 may or may not include one of the inlets of the flue gas discharge chimney 13 and / or the suction duct of the combustion air A Or more adjustable doors 12,120.

[0072] In particular, each of said doors may be arranged individually or in combination with other doors and in combination with or independently of predetermined fan speed actuators.

[0073] From an operational point of view, this means of regulating the flow of the carrier fluid 5 - whatever its specific embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com