Preparing method of pearl powder and products thereof

A pearl powder and pearl technology, which is applied in the preparation of pearl powder and superfine pearl powder, can solve the problems of powder not fine enough, large particles, remaining edges and corners of pearl particles, etc. The effect of low content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to allow your examiners to further understand the composition, features and other purposes of the present invention, the following is a preferred embodiment, which will be described in detail with the accompanying drawings, and at the same time allow those who are familiar with this technical field to implement it:

[0018] The present invention is a pearl powder production process, which mainly involves crushing and grinding pearl raw materials into fine powder, and putting the aforementioned fine powder in water to grind fine particles again, so that the aforementioned pearl fine particles are dissolved in water, and used Different components in pearl powder have different buoyancy to water to screen the active ingredients of pearls.

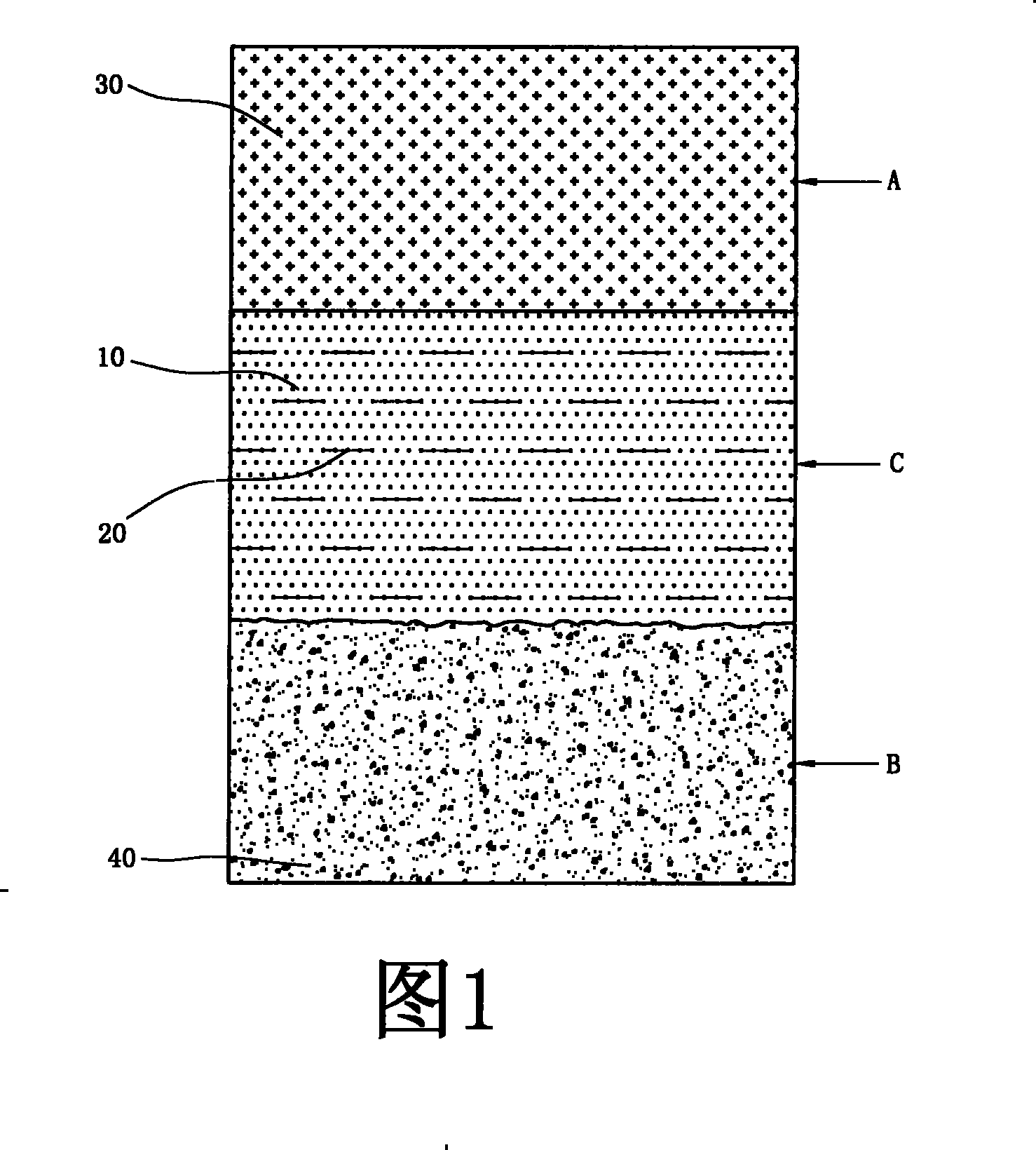

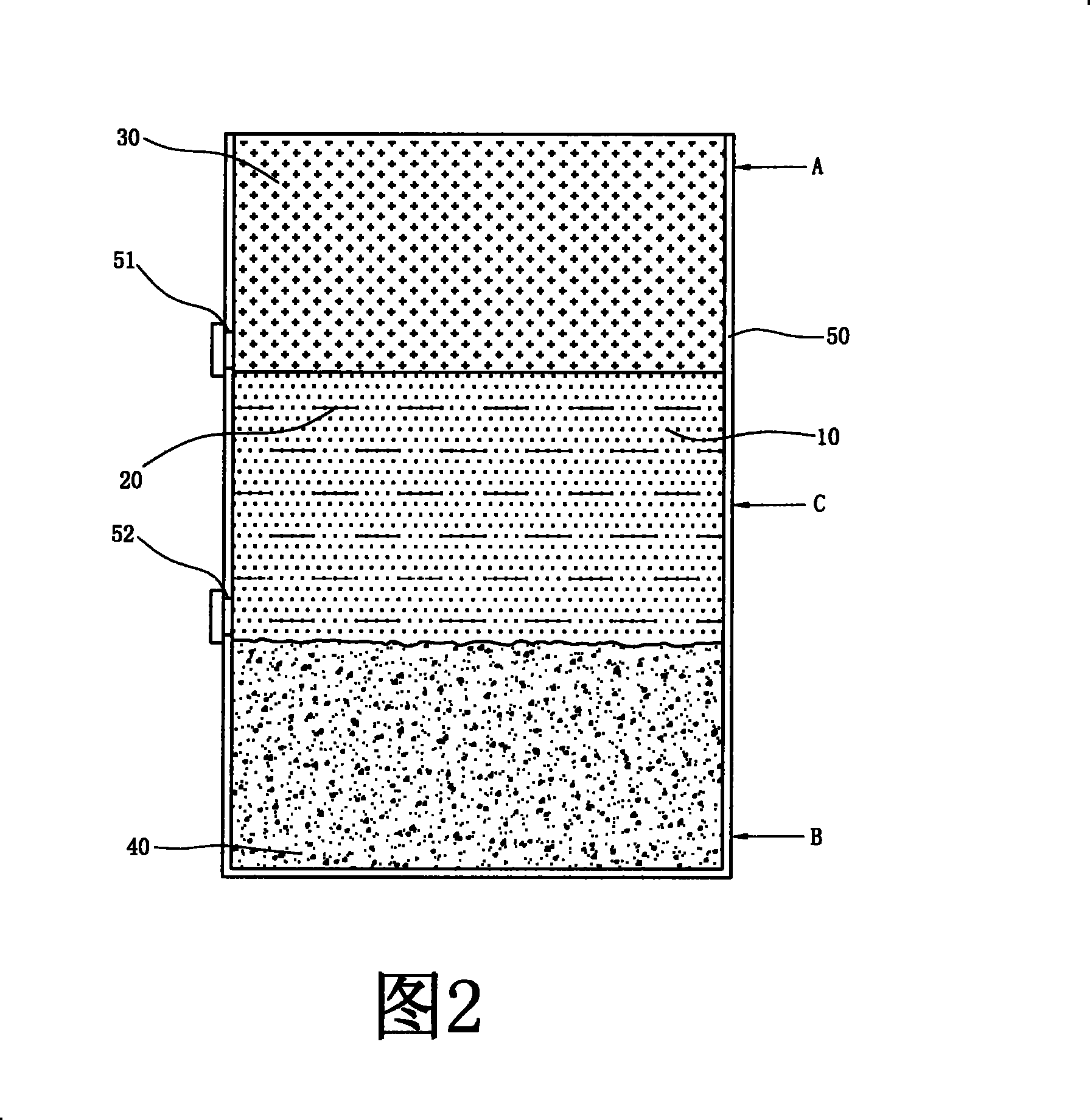

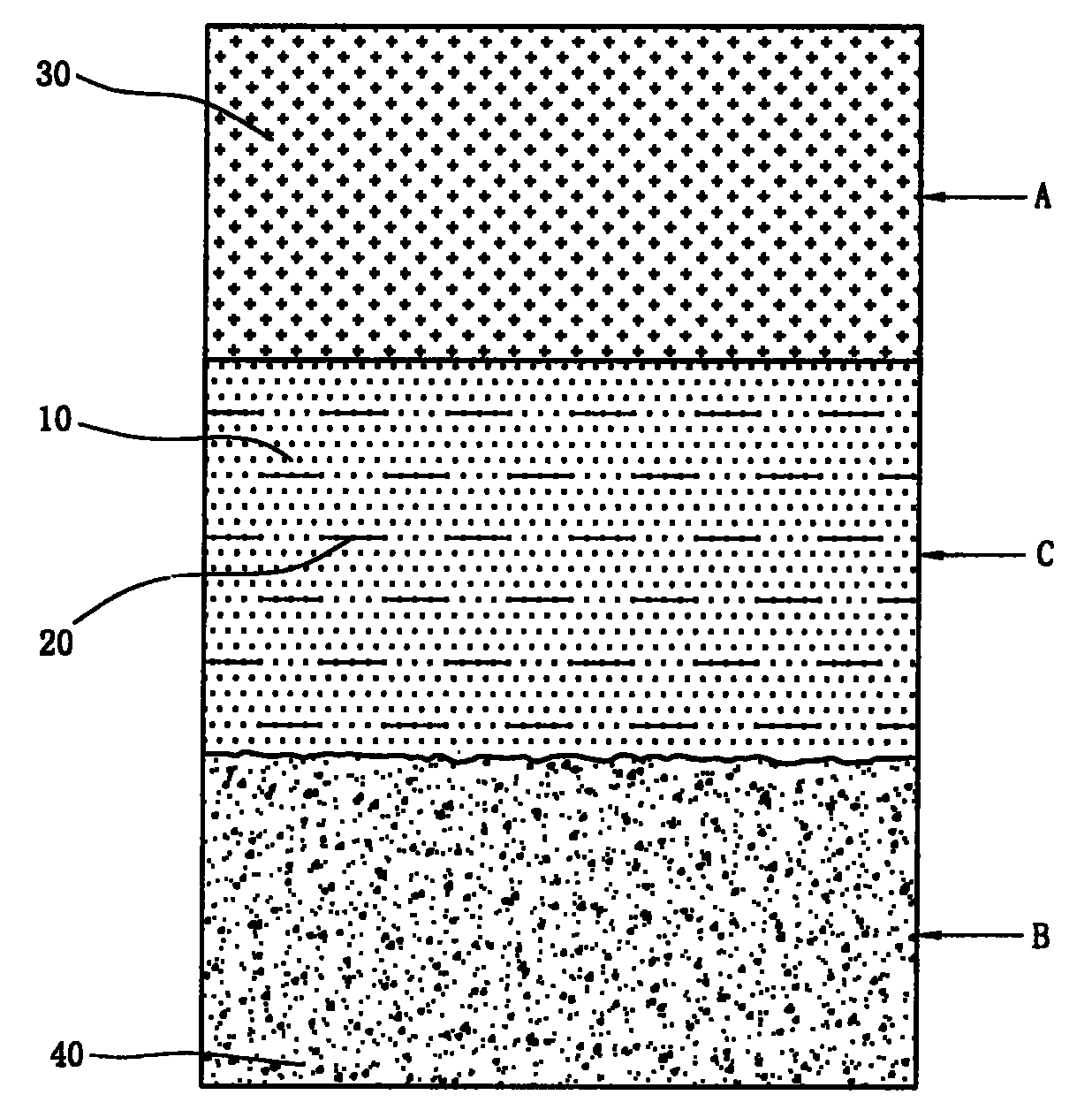

[0019] As shown in the first figure, in the aforementioned manufacturing process, pearl fine particles (pearl powder) 10 are dissolved in water 20, so that oily impurities 30 float on the upper layer A, while heavier mineral for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com