Preparation method of through-hole foamed steel

A foam steel and precursor technology, applied in the field of foam metal materials, can solve the problems of difficult gypsum removal in the manufacture of porous gypsum molds, the inability to obtain large-sized through-hole foam steel, and the inability to achieve large-scale production, etc., to achieve material reliability The effect of recycling, uniform and controllable structure, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

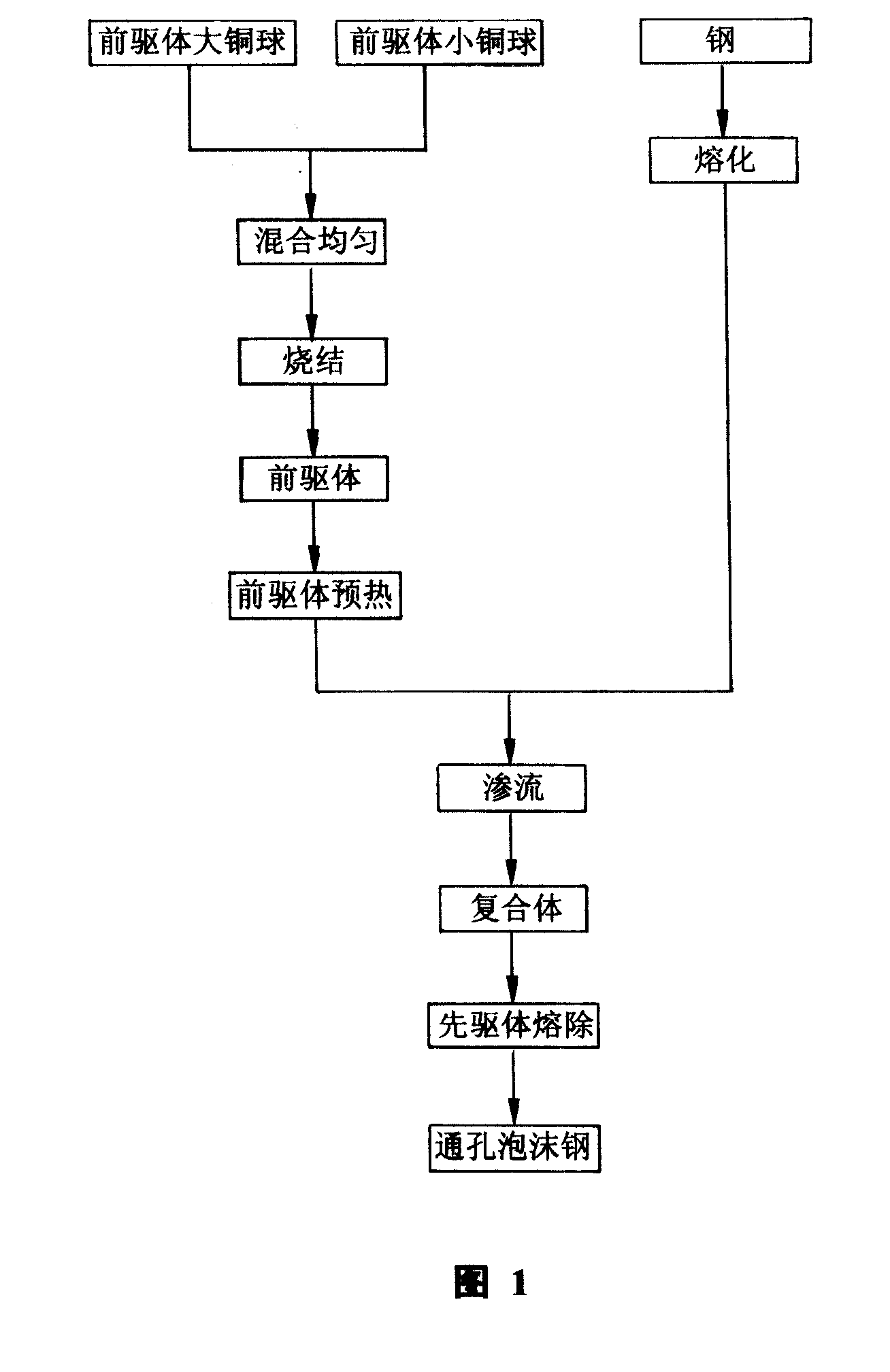

Method used

Image

Examples

Embodiment 1

[0012] Copper balls (big ball diameter 5mm, small ball diameter 0.3mm, volume ratio of large and small balls 11:1) are mixed evenly in the mixer (rotational speed: 120rpm, mixing time: 20min.;), put into reducing atmosphere H 2 Sintering in silicon carbon rod sintering furnace (sintering temperature: 950°C, sintering time 25min.) to obtain copper infiltration precursor, preheat the sintered copper infiltration precursor (preheating temperature: 880°C, preheating time 10min.) spare. At the same time, Q235 steel is heated to 1780°C in a graphite crucible with an induction furnace to melt and hold for 30 minutes. It penetrates into the copper precursor through pressure seepage (seepage pressure: 6MPa, seepage temperature: 1770°C, seepage velocity: 3mm / s) , the complex water after percolation can obtain the complex body of Q235 steel and copper precursor, and the complex body is heated and melted in the induction furnace to remove copper (heating temperature: 1350 ° C, melting tim...

Embodiment 2

[0014] Copper balls (big ball diameter 1mm, small ball diameter 0.2mm, volume ratio of big and small balls 4:1) are mixed evenly in the mixer (rotational speed: 100rpm, mixing time: 30min.;), put into reducing atmosphere H 2 Sintering in silicon carbon rod sintering furnace (sintering temperature: 900°C, sintering time 50min.) to obtain copper infiltration precursor, preheat the sintered copper infiltration precursor (preheating temperature: 850°C, preheating time 20min.) spare. At the same time, 45 steel is heated to 1700°C in a graphite crucible, melted and kept for 40min., and penetrates into the copper precursor through pressure seepage (seepage pressure: 10MPa, seepage temperature: 1680°C, seepage velocity: 4mm / s.) In the composite body after infiltration, the composite body of 45 steel and copper precursor was obtained, and the composite body was heated to remove copper (heating temperature: 1300°C, melting time 30min.), and the porosity was obtained after air cooling. ...

Embodiment 3

[0016] Copper balls (big ball diameter 4mm, small ball diameter 0.5mm, volume ratio of big and small balls 3:1) were evenly mixed in the mixer (rotational speed: 80rpm, mixing time: 50min.;), put into reducing atmosphere H 2 Sintering in silicon carbon rod sintering furnace (sintering temperature: 850°C, sintering time 60min.) to obtain copper infiltration precursor, preheat the sintered copper infiltration precursor (preheating temperature: 820°C, preheating time 30min.) spare. At the same time, eutectoid steel (containing 0.77wt.% C) is heated and melted in a graphite crucible with an induction furnace (heating temperature 1650°C, holding time 30min.), and seeps through pressure (seepage pressure: 15MPa, seepage body temperature: 1640°C , percolation velocity: 5mm / s) infiltrated into the copper precursor, and the composite after percolation was water-cooled to obtain a composite of eutectoid steel and copper precursor, and the composite was heated to remove copper (heating t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com