Electric heating pipe and manufacturing method thereof

A manufacturing method and technology for electric heating tubes, applied in the direction of the shape of the heating element, can solve the problems of no axial support, the insulating material cannot be made too thin, etc., and achieve the effect of avoiding dust, small pipe diameter, and environmental protection in production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

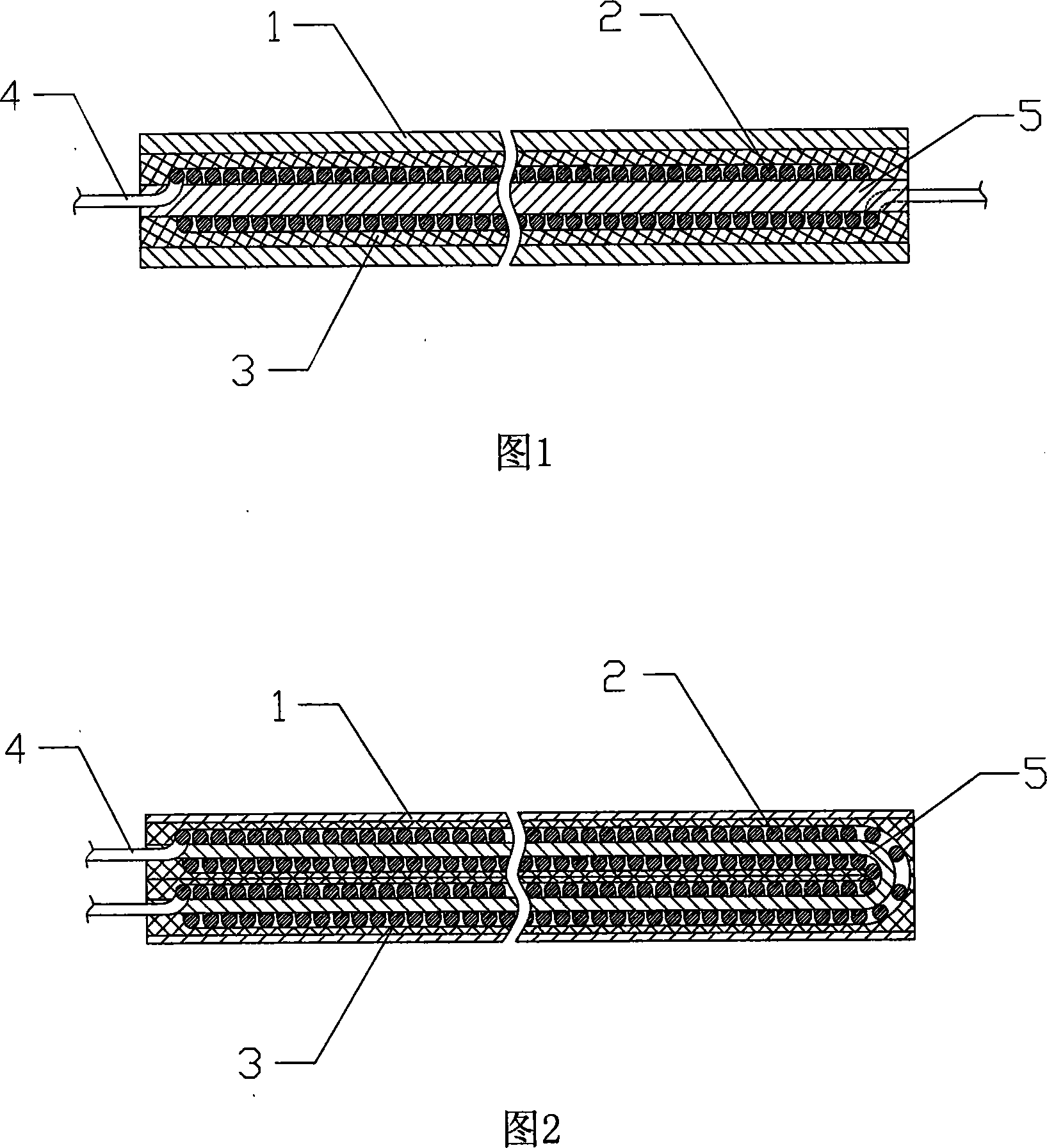

[0033] The electric heating tube has a single-head structure, the heat-resistant fiber core 5 is high silica fiber, the insulating layer 3 is a braided quartz fiber tape, and the rest are conventional electric heating tube preparation materials. The manufacturing method is as follows:

[0034] (a) Winding the heating wire 2 on the heat-resistant fiber core 5, and connecting the electrode lead rods 4 at both ends of the heating wire 2;

[0035] (b) winding the insulating layer 3 outside the heating wire 2;

[0036] (c) Cover the metal shell 1 with the insulating layer 3 to form a semi-finished product;

[0037] (d) Through the flattening process, the above-mentioned semi-finished products are made into finished products of various pipe diameters.

[0038] The electric heating tube that above-mentioned method makes, its pipe diameter φ4.

Embodiment 2

[0040] The electric heating tube has a double-head structure, the heat-resistant fiber core 5 is quartz fiber, the insulating layer 3 is a high-silica fiber braid, and the rest are conventional electric heating tube preparation materials. The manufacturing method is as follows:

[0041] (a) winding the heating wire 2 on the heat-resistant fiber core 5;

[0042] (b) Wrap the insulating layer 3 outside the heating wire 2, and connect the electrode lead rods 4 at both ends of the heating wire 2;

[0043] (c), (d) are the same as embodiment 1.

[0044] The obtained electric heating tube has a pipe diameter of φ2.5.

Embodiment 3

[0046] The electric heating tube has a double-head structure, the heat-resistant fiber core 5 is ceramic fiber, the insulating layer 3 is a mica paper tape, and the rest are conventional electric heating tube preparation materials. The manufacturing method is as follows:

[0047] (a) winding the heating wire 2 on the heat-resistant fiber core 5;

[0048] (b) winding the insulating layer 3 outside the heating wire 2;

[0049] (c) First connect the two ends of the heating wire 2 to the electrode lead rod 4, and then coat the metal shell 1 on the insulating layer 3 to form a semi-finished product;

[0050] (d) Through the tube shrinking process, the above-mentioned semi-finished products are made into finished products with various tube diameters.

[0051] The electric heating tube made by the above method has a pipe diameter of φ3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com