Method for producing foaming bottling wall from flyash cement and slurry therewith

A technology of fly ash cement and slurry, which is applied in the formulation field of slurry used in the foaming of the fly ash cement poured into walls, can solve problems such as wall cracking, achieve low comprehensive cost, save the total cost of steel materials, and reduce transportation costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

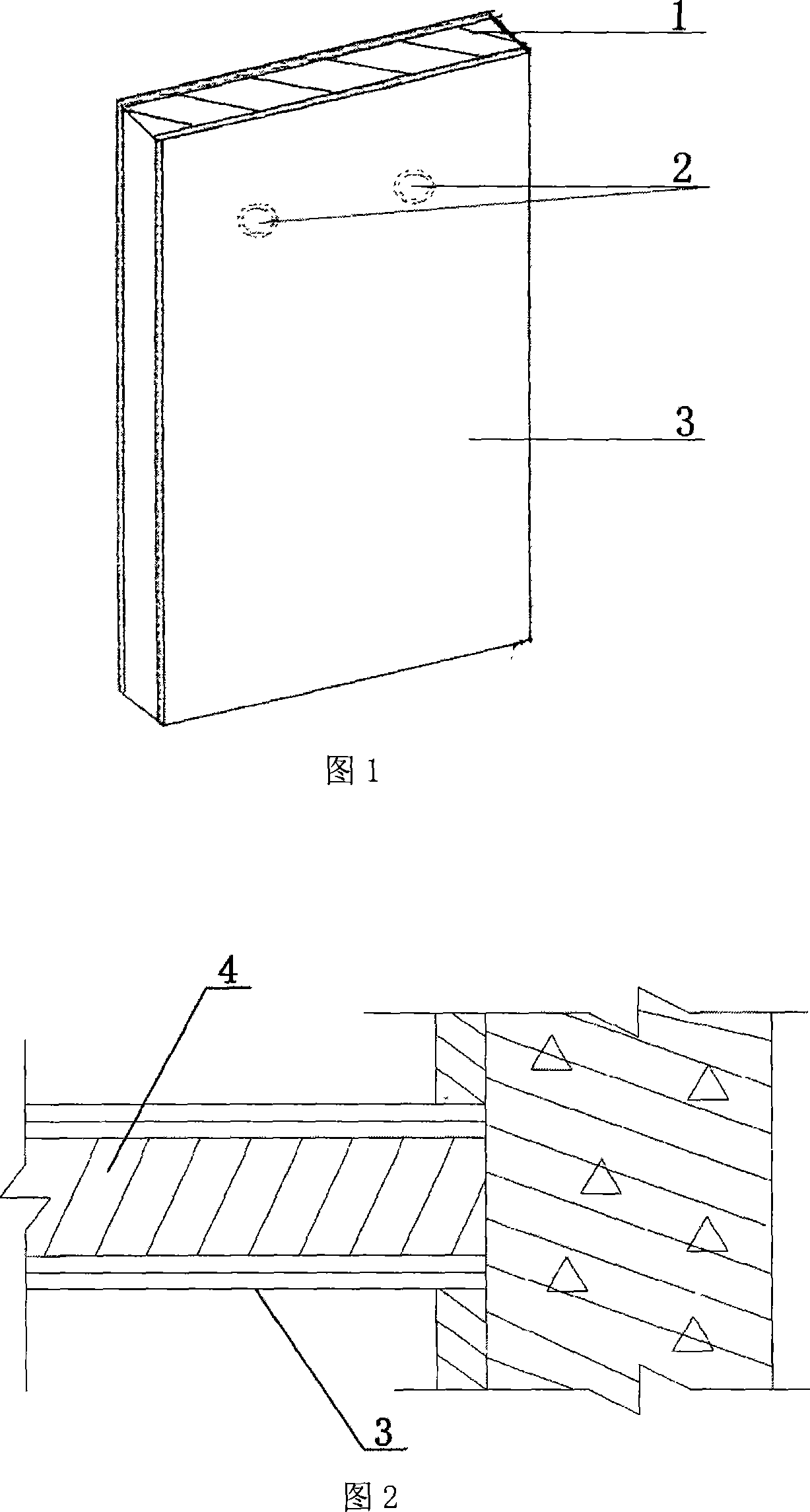

[0023] As shown in Figure 1, the production method of fly ash cement foaming perfusion wall is carried out as follows:

[0024] First, mix according to the ratio of each component to obtain the slurry 1. The proportioning relationship of each component described, its parts by weight are as follows: 425# cement 29, fly ash 19, diffusing agent 1.5, water 38, blowing agent 0.2, quick-setting agent 0.2, gelling agent 1.5, reinforcing agent 1.0 , 801 glue 1.0.

[0025] Then the tire board 3 is installed and fixed, and the filling machine is used to pour the slurry 1 into the cavity surrounded by the tire board 3 through the injection port 2; as shown in Figure 2, the wall body 4 is obtained after the slurry 1 is cured, Then remove the tire board 3.

[0026] The wall body of the invention can be puttyed directly and is very practical.

Embodiment 2

[0028] The production method of this embodiment is the same as that of Example 1, except that each material is mixed by the following parts by weight: 425# cement 28, fly ash 19, diffusing agent 1.5, water 38, blowing agent 0.2, quick-setting agent 0.2 , Gelling agent 1.5, reinforcing agent 1.5, 801 glue 1.2.

Embodiment 3

[0030] The production method of this embodiment is the same as that of Example 1, except that each material is mixed according to the following parts by weight: 425# cement 32, fly ash 19, diffusing agent 1.5, water 38, blowing agent 0.2, quick-setting agent 0.2 , Gelling agent 1.5, reinforcing agent 1.2, 801 glue 1.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com