Water-base passivator formulation and technique for anti-rust treatment of steel members

A technology of anti-rust treatment and passivation agent, which is applied in the direction of metal material coating process, etc., can solve the problems of environmental pollution, short scrap cycle, general anti-rust effect, etc., and achieve the effect of cost reduction and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

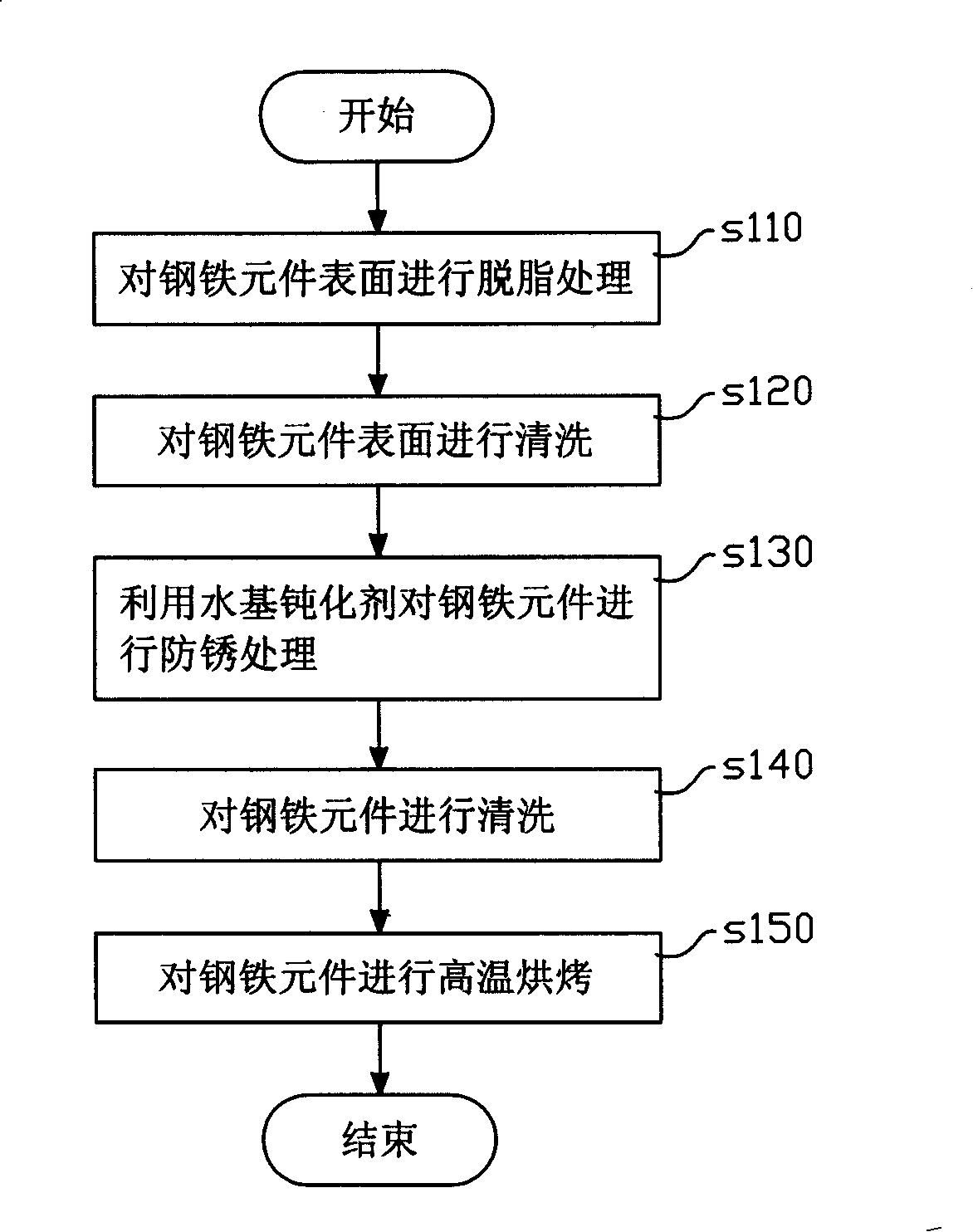

Method used

Image

Examples

Embodiment 1

[0046] According to the above steps, the iron and steel elements treated with the water-based passivation agent solution disclosed in the present invention and the iron and steel elements treated with the purchased organic passivation solution--Xin Promise will be tested outdoors for two days, and the results of the test comparison As shown in Table 1.

[0047] Table 1: Treated with water-based passivator solution of the present invention and treated with Xin promise

[0048] Comparison of performance test results of steel components

[0049] this invention

Xin Promise

Rusted area (%)

30

50

[0050] In summary, compared with the prior art, the present invention produces the following technical effects:

[0051] The water-based passivation agent formula disclosed by the invention can effectively carry out anti-rust treatment on iron and steel components, the raw material cost of the water-based passivation agent is relatively low, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com