Retainer cone, and bag filter retainer having the same

A retainer and bag filter technology, applied in the direction of dispersed particle filtration, chemical instruments and methods, separation methods, etc., can solve the problems that the filter cloth 55 is easy to be damaged, the suction efficiency is reduced, and the dusty airflow cannot pass through the filter cloth, etc., to achieve expansion Effective filter area, increased service life, and improved dust collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

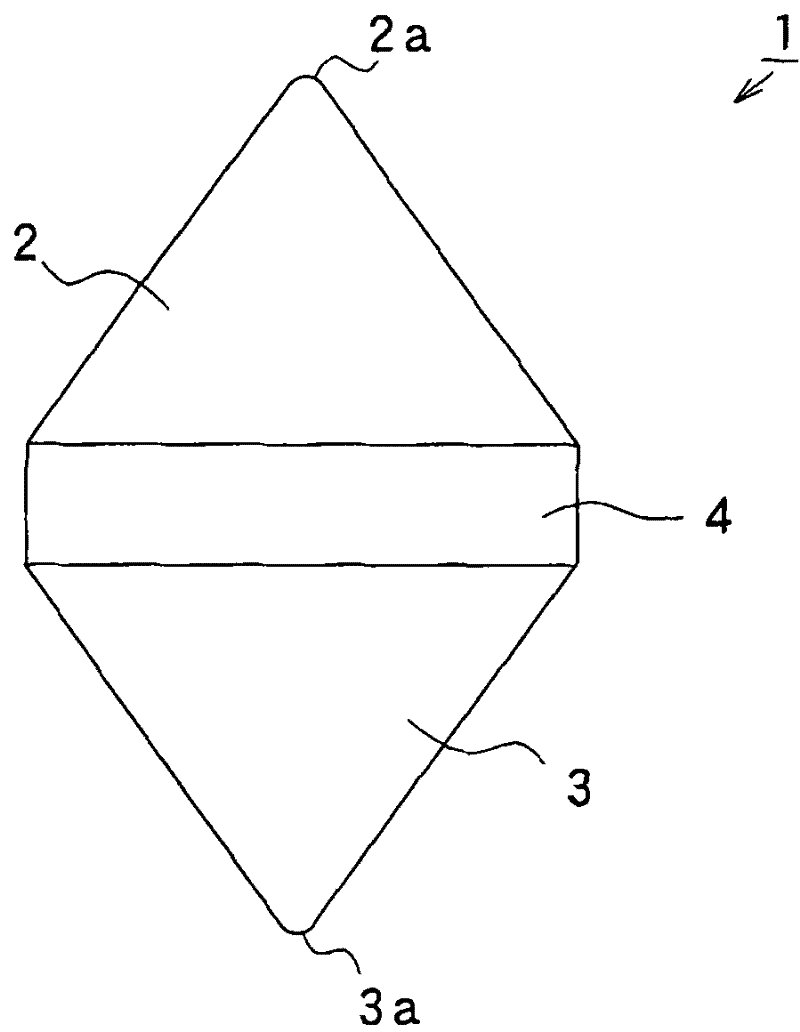

[0087] figure 1 It is a front view of the cage cone of the first embodiment of the present invention.

[0088] exist figure 1 Among them, 1 is the cone for retainer of the first embodiment of the present invention formed in a conical top shape (bacus bead shape), and 2 is the cone for retainer 1 formed in a conical shape by contracting at the upper end in the longitudinal direction toward the upper end. The upper constriction part, 2a is the top of the upper constriction part 2, 3 is the lower end constriction part of the retainer cone 1 constricted toward the lower end in the longitudinal lower end, and formed into a conical shape, 3a is the top of the lower constriction part 3, and 4 is A cylindrical middle portion is formed between the upper constriction 2 and the lower constriction 3 .

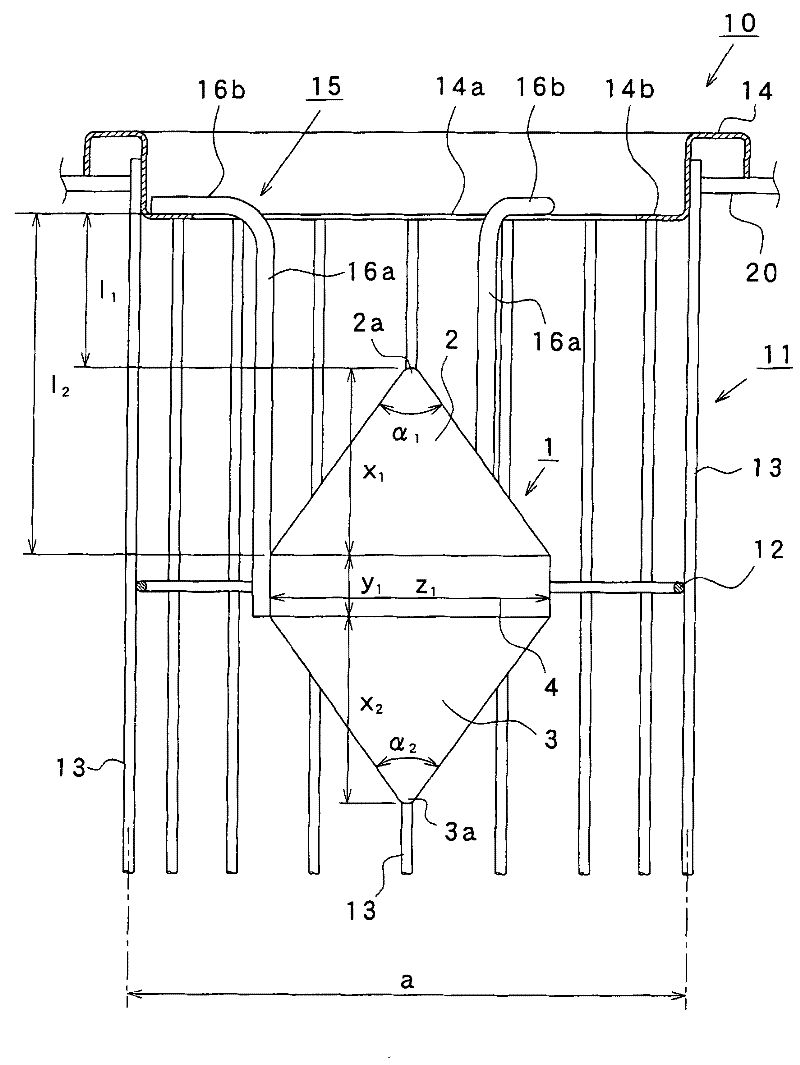

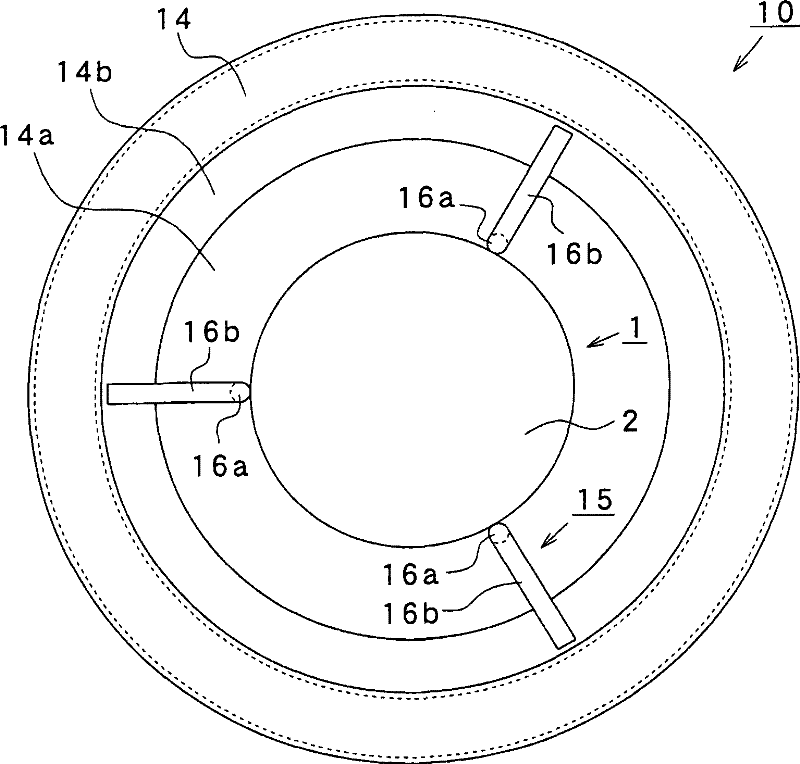

[0089] figure 2 It is a sectional front view of main parts of the bag filter holder having the holder cone according to the first embodiment of the present invention, image 3 It is a...

no. 2 approach

[0130] Fig. 6(a) is a sectional front view of main parts of a holder for a bag filter having a cone for a holder according to a second embodiment of the present invention, and Fig. 6(b) is a sectional view along line A-A of Fig. 6(a) . In addition, the same reference numerals are assigned to the same components as those in the first embodiment, and description thereof will be omitted.

[0131] In FIG. 6, the bag filter holder 10a having the holder cone of the second embodiment is different from the first embodiment in that four fixing members 15a are arranged radially at equal angular intervals on the outer periphery of the holder cone 1c. In the radial direction of the holder body 11 , it is welded to the fixing ring 12 of the holder body 11 for fixing.

[0132] If one end of the fixing member 15a is fixed on the outer periphery of the retainer cone 1c by welding or screwing, etc., the retainer cone 1c can be inserted into the holder body 11, and the other end of the fixing ...

no. 1 example

[0140] The pressure during backwashing was measured using the bag filter holder having the holder cone described in the first embodiment.

[0141] In the bag filter holder 10 used for pressure measurement, the diameter a of the holder body 11 is 160 mm, the overall length of the holder body 11 is 9000 mm, the overall length of the cone 1 for the holder is 128 mm, and the cone 1 for the holder is The angle α of the tops 2a, 3a of the upper constriction 2 and the lower constriction 3 of 1 、α 2 = 70 degrees, the diameter z of the cylindrical middle part 4 of the cone 1 for the cage 1 =80mm, the length y of the middle part of the cylinder 4 1 =18mm, installation height l from the top of the annular flange portion 14 to the upper end of the cylindrical intermediate portion 4 of the cone 1 for the holder 2 =100mm (refer to figure 2 ).

[0142] From the nozzle 30a toward the bag filter holder 10, a pulse jet (compressed air) of 294 kPa was sprayed for 0.2 seconds, and the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com