Natural gas engine electromagnetic valve jet drive circuit

A driving circuit and engine technology, which is applied in the direction of engine components, engine control, combustion engine, etc., can solve problems such as inability to effectively prevent misinjection, impossibility to improve accuracy, and heavy software workload, and achieve simplified injection drive control methods and high reliability. Improved, highly configurable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with embodiment and accompanying drawing, further illustrate the present invention.

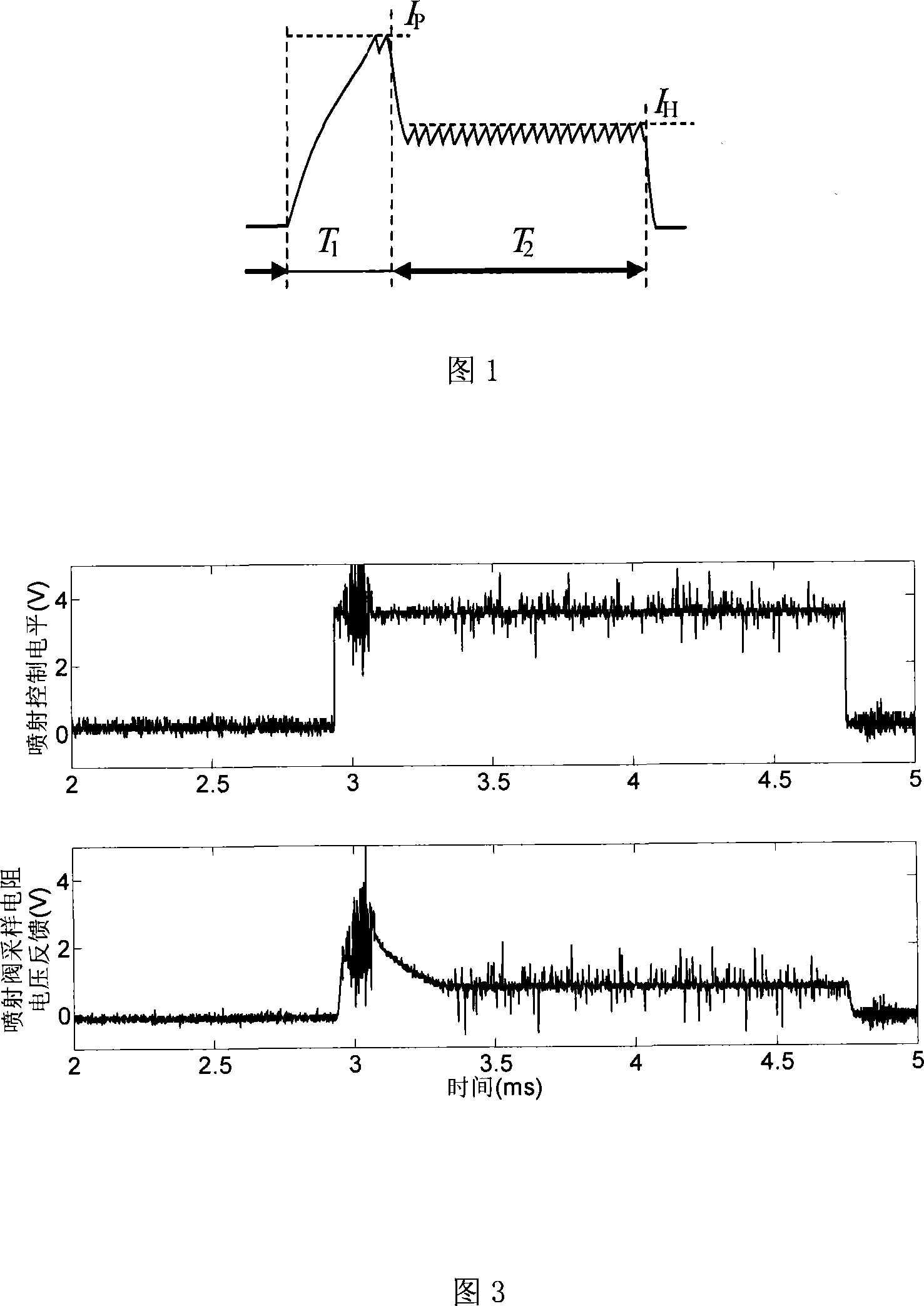

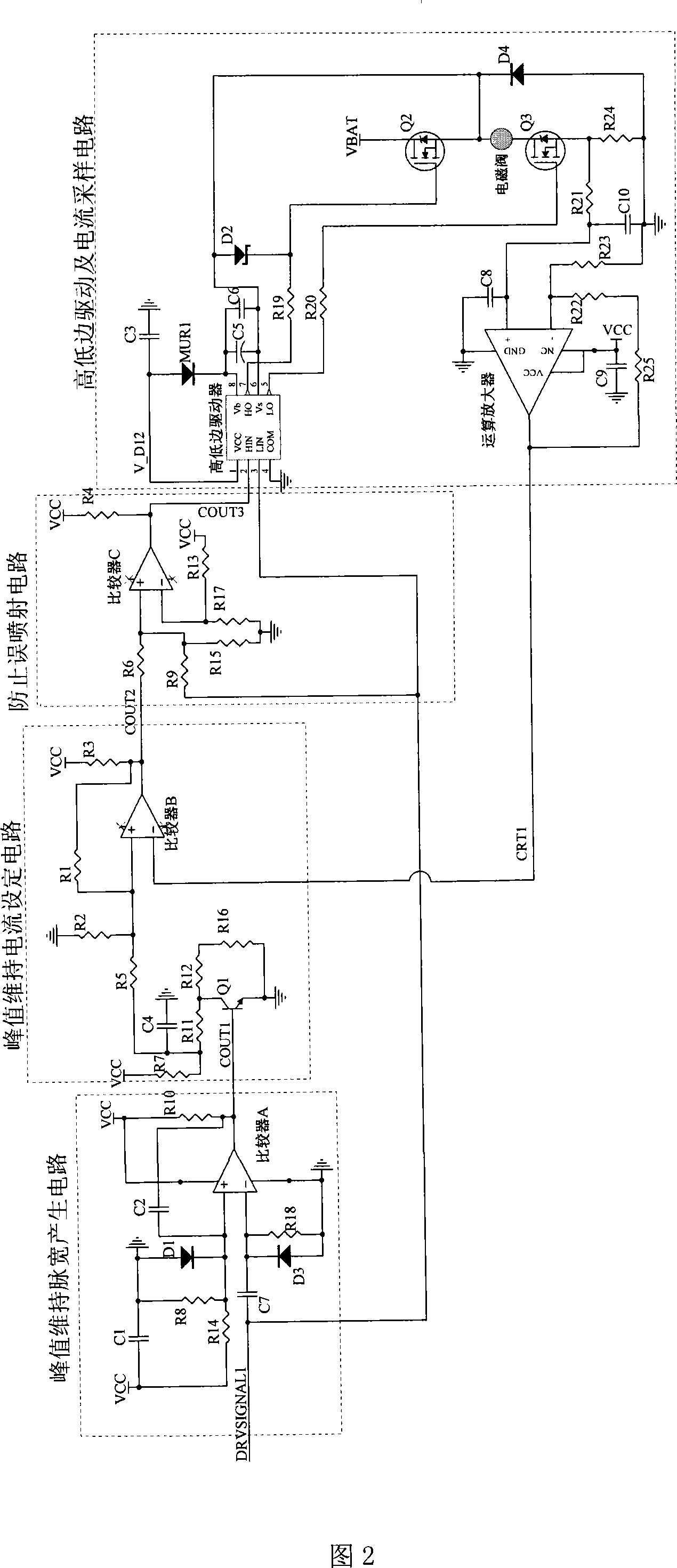

[0018] Figure 1 is a schematic diagram of the driving current. Fig. 2 is a schematic diagram of the present invention. Fig. 3 is a partial signal diagram of the working process of the present invention.

[0019] The whole drive circuit consists of four parts: peak sustain pulse width generation circuit, peak sustain current setting circuit, false injection prevention circuit, high and low side drive and current sampling circuit. The peak sustain pulse width generating circuit is composed of a comparator A and two RC circuits. The injection drive pulse signal is input to one RC circuit, and then input to the negative port of comparator A of LM2902. When the pulse input terminal is at low level, the level at the positive terminal of comparator A is higher than that at the negative terminal, then comparator A outputs low level. After the pulse input terminal become...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com