Straight-through type non-contact hermetic sealing structural design for grease lubricating bearing

A structural design, non-contact technology, applied in the field of bearing sealing, can solve problems such as increased management and production costs, uncertain life of spindle bearings, speed limit at the contact surface, etc., to achieve convenient processing, convenient installation and debugging, minimum pressure requirements Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

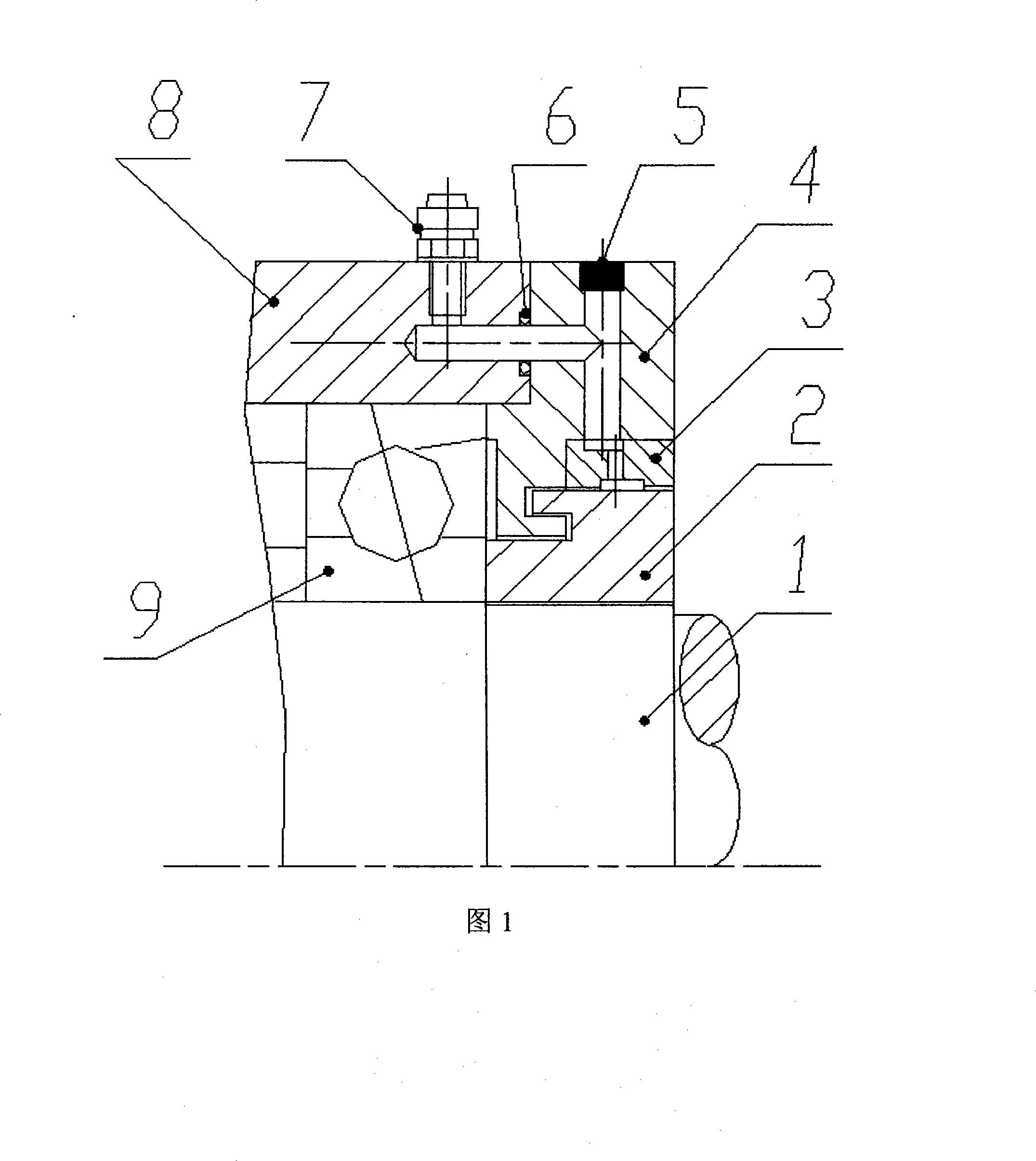

[0018] As shown in Figure 1: the front cover (4) is an assembly, the gas distribution ring (3) and the front cover (4) adopt interference fit, and are assembled together by press-fitting. Straight air hole outer end is blocked with plug (5). The front cover (4) and the housing (8) are reliably connected with bolts. During installation, it must be ensured that the horizontal air holes of the housing (8) and the front cover (4) are aligned and communicated, and the O-ring (6) is tightly leak-proof.

[0019] During work, the compressed air enters the horizontal air passage of the housing (8) of the rotating shaft (1) through the air intake nozzle (7) fixed on the housing (8), and then enters the horizontal air passage and vertical air passage of the front cover (4). into the air cavity formed by the front cover (4) and the outer diameter ring groove of the gas distribution ring (3), the compressed air is gathered and evenly distributed, and then sprayed out at high speed through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com