Double temperature cold water/cold air unit

A cold water and cold air technology, applied in refrigerators, compressors, refrigeration and liquefaction, etc., can solve the problems of difficult adjustment, lack of availability, increase initial investment of air conditioning systems, etc., to achieve high energy efficiency ratio and reduce investment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

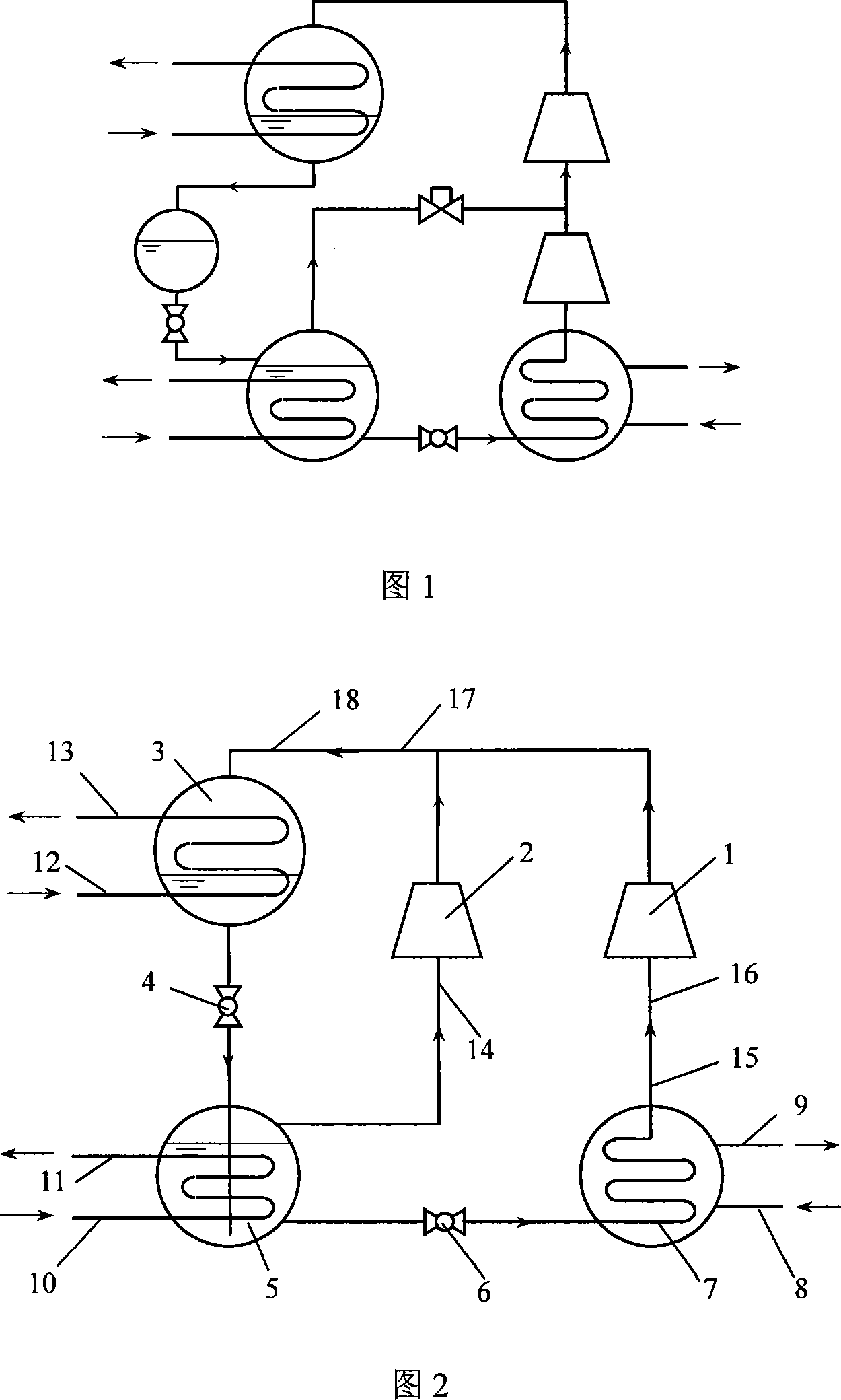

[0026] Fig. 2 is a schematic diagram of the structure and refrigeration cycle of a dual-temperature cold water / cooler air unit provided by the present invention. Fig. 2 shows a schematic diagram of a refrigeration cycle of a dual-temperature chiller unit for producing medium-temperature and low-temperature cold water, which includes two parallel-connected medium- and low-temperature compressors. The dual-temperature chiller is composed of a low-temperature stage compressor 1, a medium-temperature stage compressor 2, a condenser 3, a high-temperature stage throttle valve 4, a medium-temperature evaporator 5, a low-temperature stage throttle valve 6, and a low-temperature evaporator 7; The warm and cold water inlet 10 enters the water channel of the medium-temperature evaporator 5, and after being cooled by the medium-temperature refrigerant, it flows from the medium-temperature cold water outlet 11 to the medium-temperature heat exchanger of the air-conditioning system with inde...

Embodiment 2

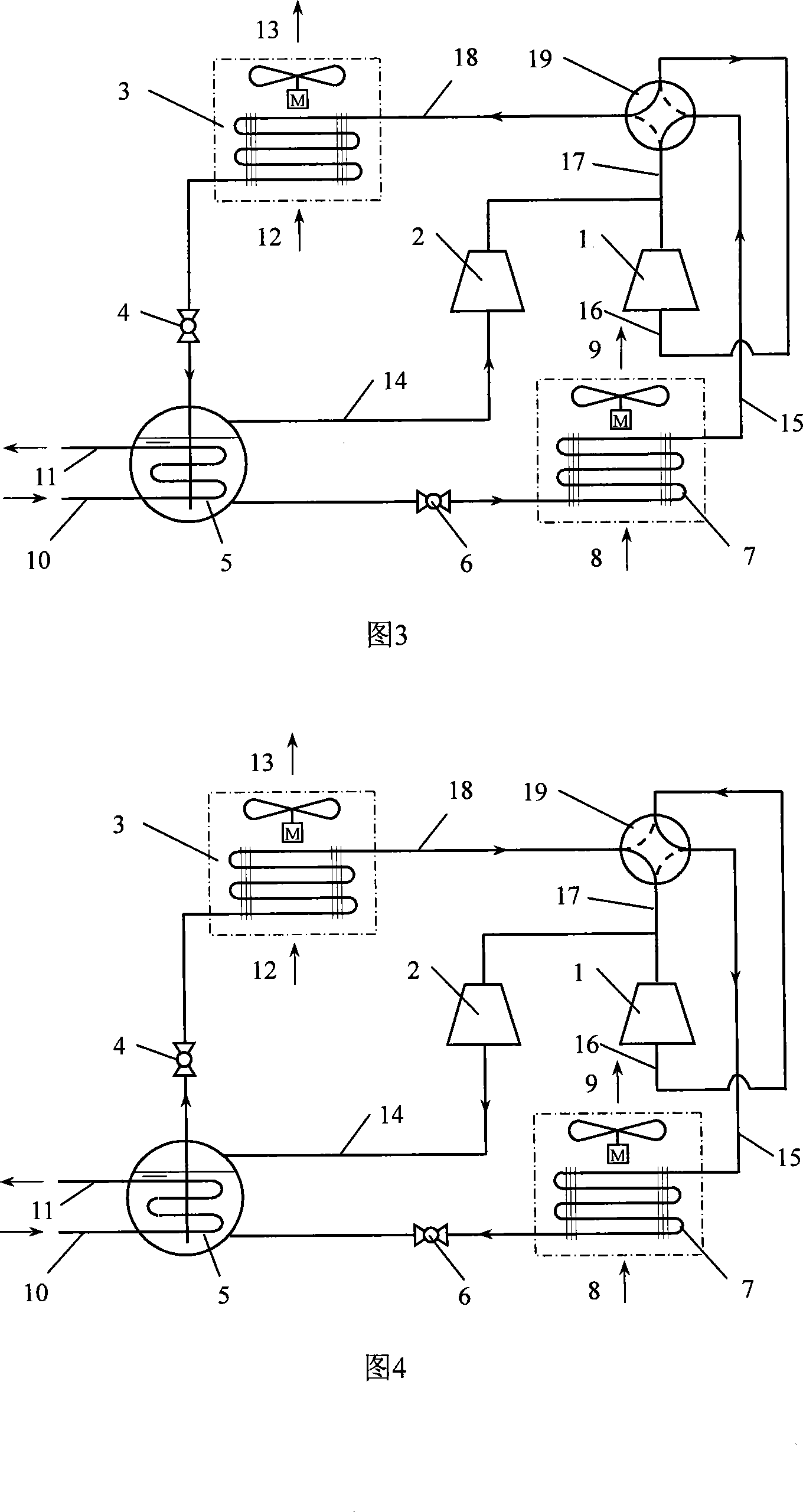

[0031] Fig. 3 is a schematic diagram of the structure and refrigeration cycle of the second embodiment of a dual-temperature cold water / air cooling unit provided by the present invention. Fig. 3 shows the schematic diagram of the refrigeration cycle of this embodiment, and Fig. 4 shows the schematic diagram of the heating cycle of this embodiment. This embodiment is the heat pump form of the above-mentioned embodiment 1. The heat pump type dual-temperature cold / hot water / air blower unit consists of a low-temperature stage compressor 1, a medium-temperature stage compressor 2, a condenser 3, a high-temperature stage throttle valve 4, and a medium-temperature stage compressor. An evaporator 5, a low-temperature stage throttle valve 6, a low-temperature evaporator 7 and a refrigerant four-way reversing valve 19 are formed. Its structural principle is exactly the same as embodiment 1, the difference is:

[0032] (1) The condenser 3 in embodiment 1 is a water-cooled condenser, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com