Electronic material hexabromocyclododecane content determination method

A technology for measuring hexabromocyclododecane and its method, which is applied in the field of flame retardant content determination, and achieves the effects of easy implementation, convenient method, and reliable implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

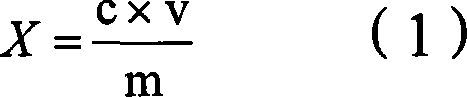

[0021] Embodiment 1, the detection of hexabromocyclododecane content in the plastic shell:

[0022] Take 1.0006g of the solid sample to be tested (accurately weighed to 0.0001g), place it in a conical flask, add 60mL of 1:1 n-hexane and acetone, and reflux at 70°C for 4 hours; take it out and cool it to room temperature, and transfer the extraction solution into 250ml In a pear-shaped bottle, use a K-D concentrator to concentrate at 40°C to nearly dryness, and add 2ml of n-hexane.

[0023] Prepare a glass tube (20mm×350mm), one end of which is plugged with solvent-cleaned glass wool, and a 250ml receiver is connected below; add 1g of dehydrated sodium sulfate, 1g of silica gel, 4g of acid-modified silica gel and 1g of dehydrated Sodium sulfate, the column was rinsed with 30 ml of hexane, and the rinsed hexane was discarded. Add the previously concentrated sample, elute the column with 130 mL of hexane and save the entire eluate. The volume of the solution was rotary evaporat...

Embodiment 2

[0048] Embodiment 2, hexabromocyclododecane content determination in PCB board:

[0049] Take 1.0006g of the solid sample to be tested (accurately weighed to 0.0001g), place it in a conical flask, add 60mL of 1:1 n-hexane and acetone, and reflux at 70°C for 4 hours; take it out and cool it to room temperature, and transfer the extraction solution into 250ml In a pear-shaped bottle, use a K-D concentrator to concentrate at 40°C to nearly dryness, and add 2ml of n-hexane.

[0050] Prepare a glass tube (20mm×350mm), one end of which is plugged with solvent-cleaned glass wool, and a 250ml receiver is connected below; add 1g of dehydrated sodium sulfate, 1g of silica gel, 4g of acid-modified silica gel and 1g of dehydrated sodium sulfate. The column was washed with 30 ml of n-hexane, and the washed n-hexane was discarded. Add the previously concentrated sample, elute the column with 130 mL of hexane and save the entire eluate. The volume of the solution was rotary evaporated to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com