Artificial board formaldehyde burst size detection system

A formaldehyde emission and detection system technology, which is applied in the field of detection systems for quickly detecting formaldehyde emission from wood-based panels, can solve the problems of low test accuracy, violation of energy saving and consumption reduction, and narrow test range, so as to facilitate the placement of test pieces , improve stability, and adjust the effect of short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

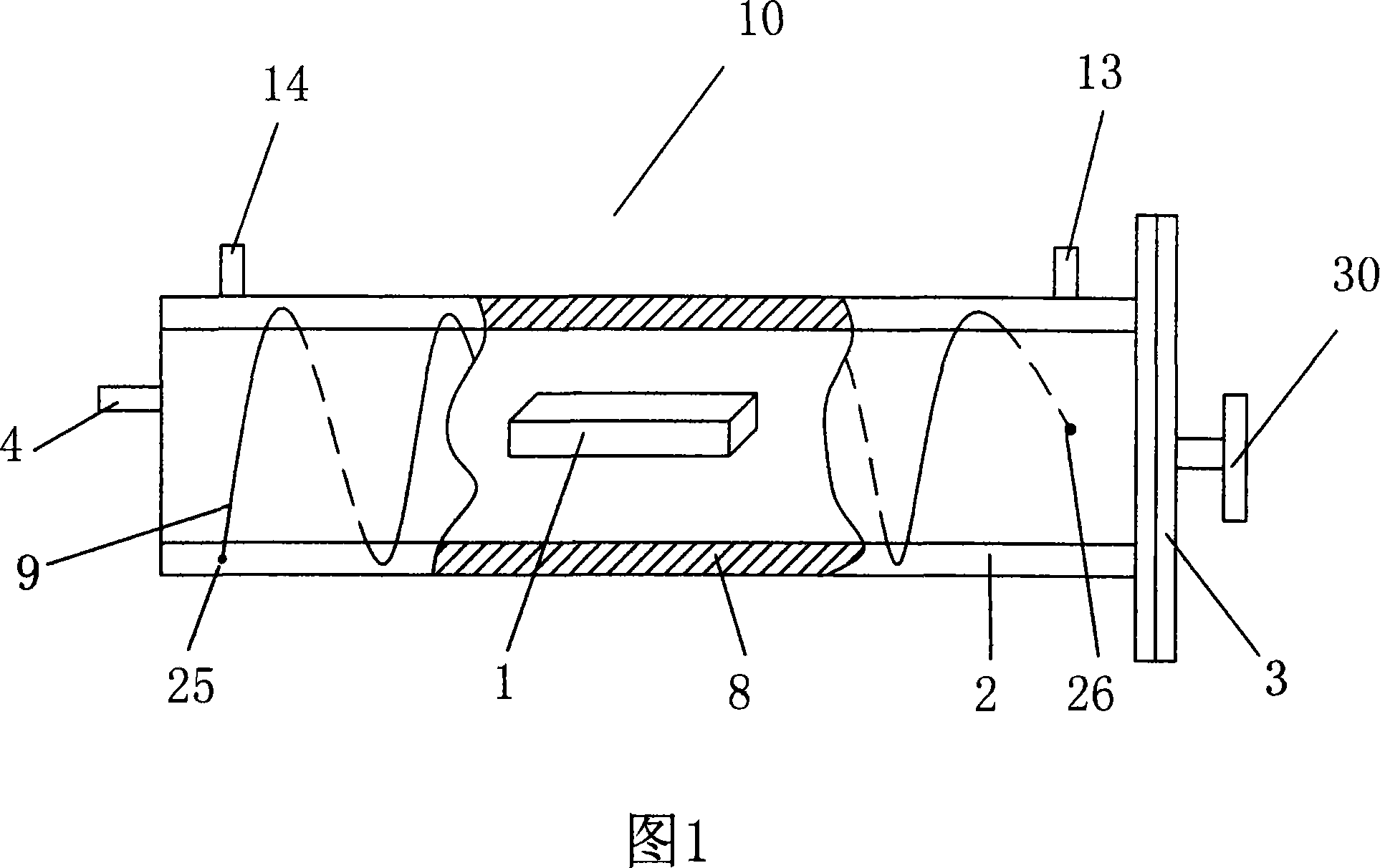

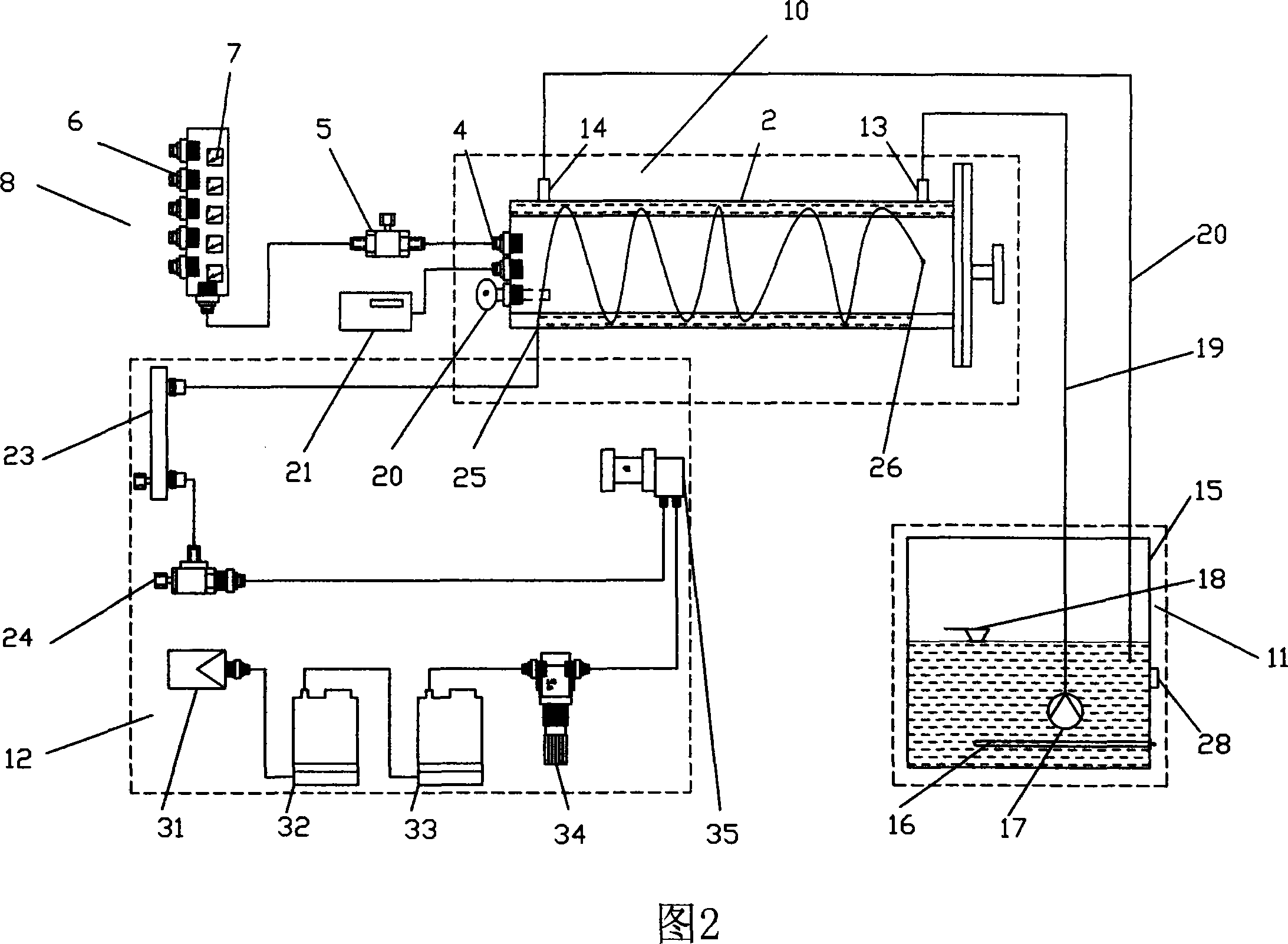

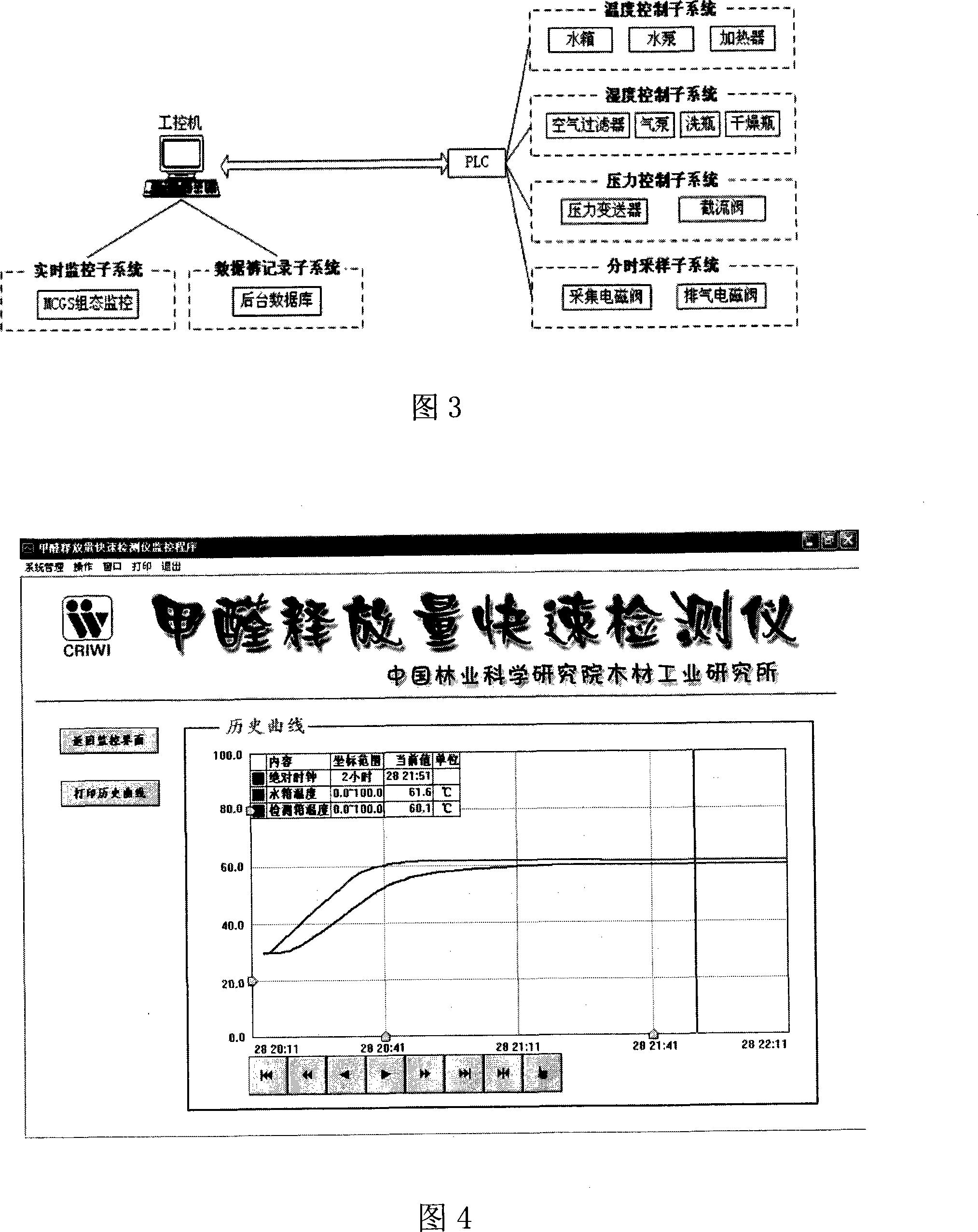

[0018] A preferred embodiment of the present invention will be described below in conjunction with the accompanying drawings. Fig. 1 is a cross-sectional view of the detection box of the formaldehyde emission detection system of wood-based panels in the present invention, and the tested test samples are placed in the detection box device 10 for detection. The basic working principle of the test is to place a test sample 1 with a certain exposure area in the test box 2, seal it with the test box sealing door 3, adjust and control the temperature, humidity and pressure in the test box to make it meet Standard Test Conditions. Formaldehyde is released from the test sample and mixes with the air in the chamber. The mixed air communicates with the one-way shut-off valve 5 outside the test box through the air outlet hole 4 on the side wall of the test box. These mixed gases pass through different electromagnetic valves 6 and lead to different detection bottles 7, which contain a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com