Method for producing solar water-based high pressure high purity oxyhydrogen fuel for space vehicle

A technology of fuel preparation and solar energy, applied in the field of fuel preparation for space vehicles, can solve problems such as high risk, pollution, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

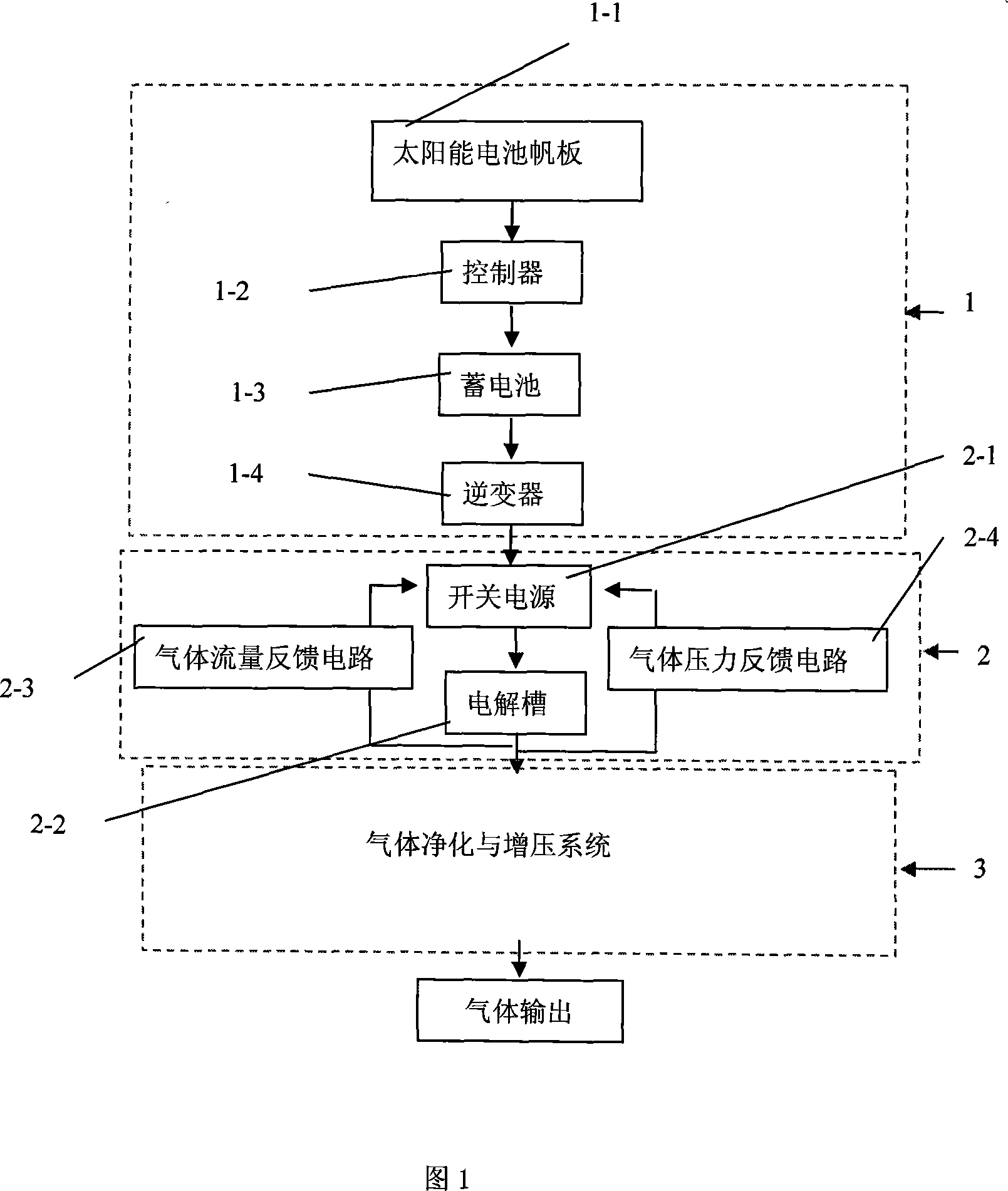

[0009] Specific implementation mode one: the following combination figure 1 This embodiment will be specifically described. This embodiment consists of the following steps: 1. The solar energy is converted into electrical energy by the solar panel in the solar independent power supply system 1, which is supplied to the electrolyzed water system 2 and the hydrogen and oxygen purification and pressurization system 3; 2. Electrolyzed water System 2 uses the electric energy output by solar independent power supply system 1 to decompose water into hydrogen and oxygen; 3. Hydrogen and oxygen purification and pressurization system 3 dries and boosts hydrogen and oxygen for use. Hydrogen and oxygen are used as the working fluid of the engine to generate thrust.

[0010] The solar independent power supply system 1 is composed of a solar battery sail 1-1, a controller 1-2, a storage battery 1-3 and an inverter 1-4, and the output end of the solar battery sail 1-1 is connected through ...

specific Embodiment approach 2

[0013] Specific implementation mode two: the following combination figure 1 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is that the electrolyzed water system 2 also includes a gas flow feedback circuit 2-3 and a gas pressure feedback circuit 2-4, and the gas flow feedback circuit 2-3 collects the oxygen in the electrolytic cell 2-2 and the flow of the hydrogen outlet to control the current value output by the switching power supply 2-1, so that the flow of the oxygen and hydrogen outlets of the electrolytic cell 2-2 remains within the allowable range; the gas pressure feedback circuit 2-4 collects the electrolytic cell 2- 2’s oxygen and hydrogen outlet pressures to control the current value output by the switching power supply 2-1, so that the pressure of the oxygen and hydrogen outlets of the electrolyzer 2-2 remains within the allowable range; their two functions are to electrolyze water When the generated gas pre...

specific Embodiment approach 3

[0014] Specific implementation mode three: the following combination figure 2 with 3 This embodiment will be specifically described. The difference between this embodiment and the first embodiment is that the electrolytic cell 2-2 is an alkaline electrolytic cell, a polymer film electrolytic cell or a solid oxide electrolytic cell.

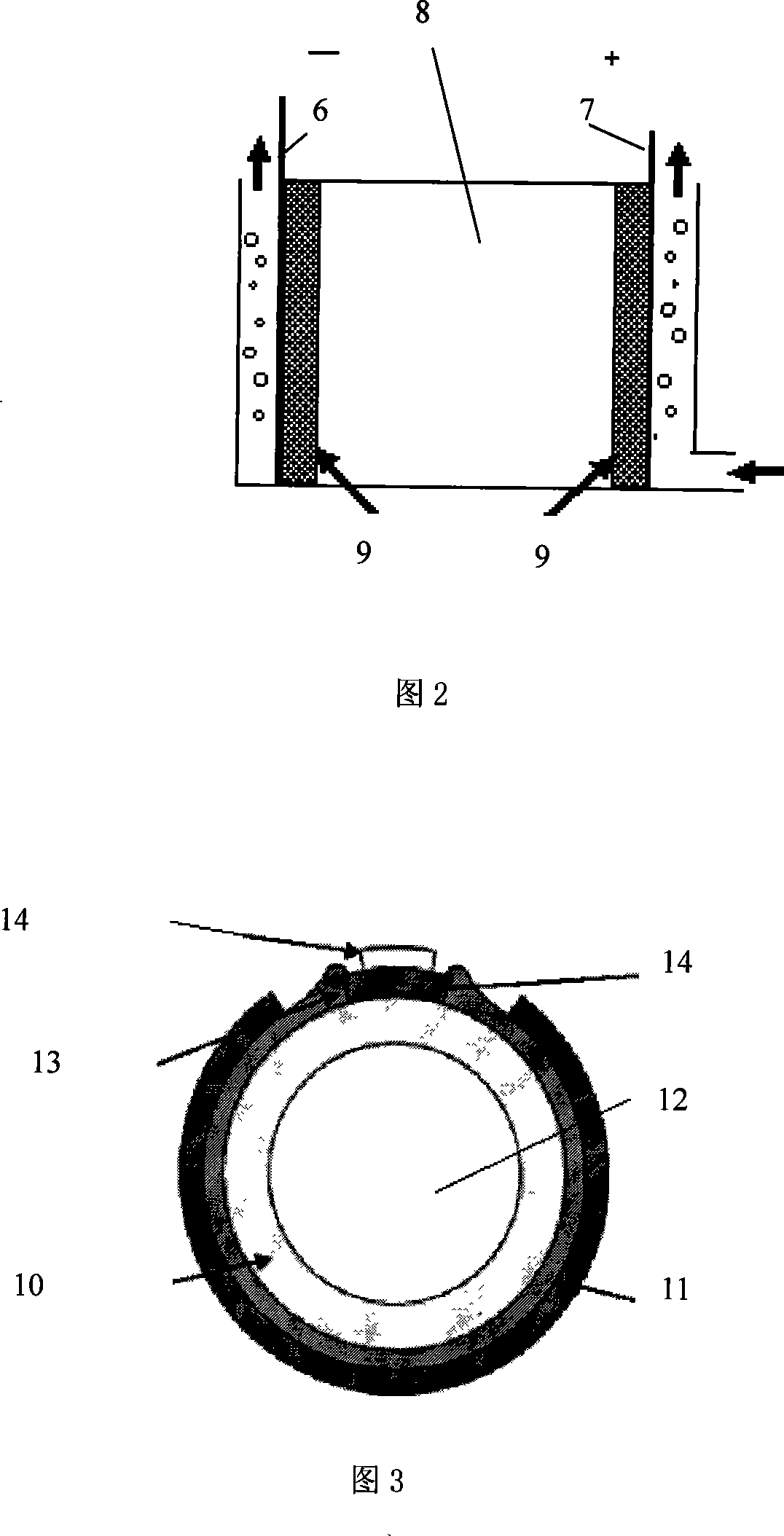

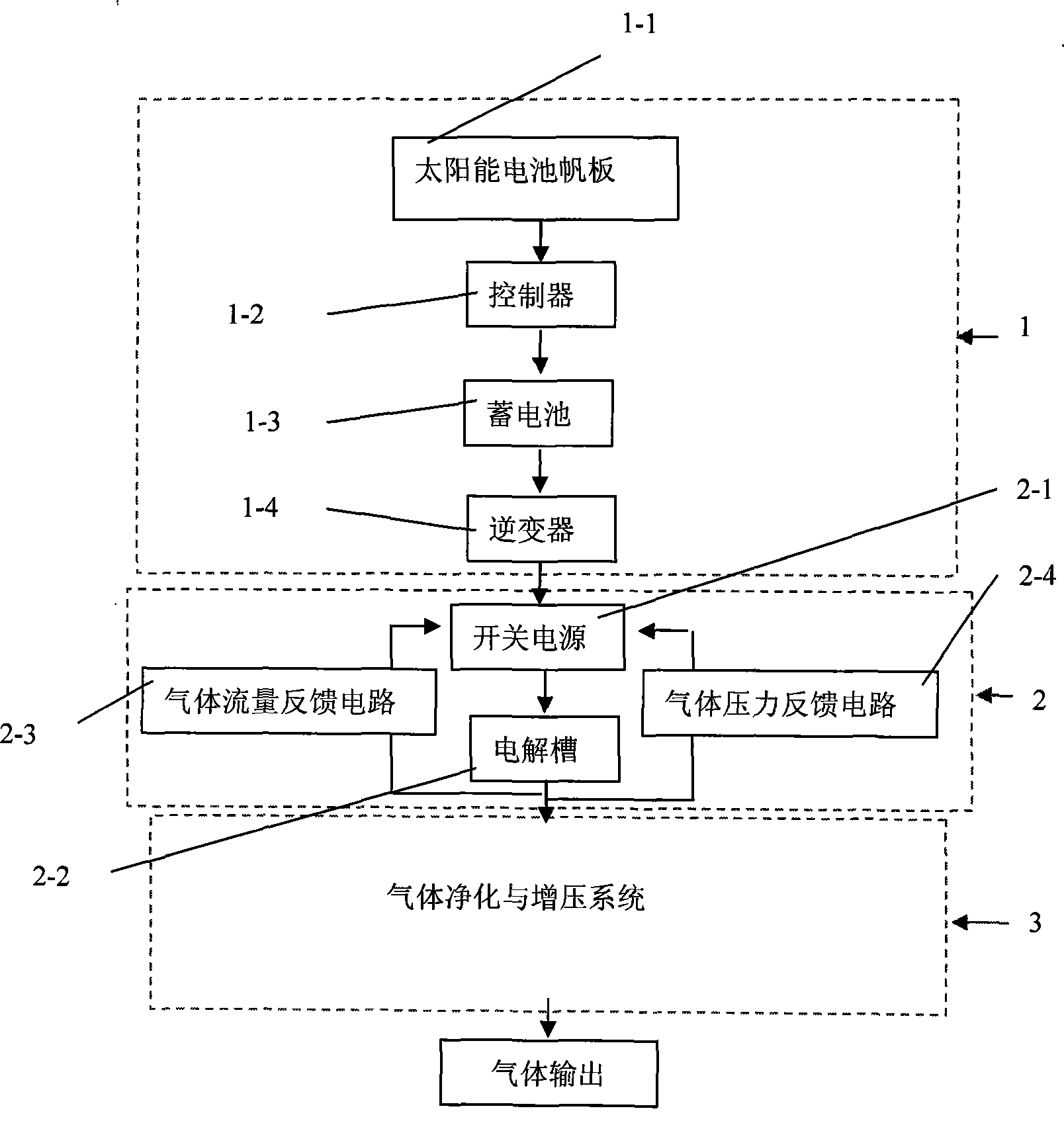

[0015] figure 2 Is the schematic diagram of the structure of the polymer film electrolyzer. The polymer film electrolyzer is mainly composed of an anode 6, a cathode 7 and a proton exchange membrane 8. The proton exchange membrane 8 usually forms an integrated structure with the electrode catalyst 9. In this structure, a porous platinum material is used as the structure of the electrode catalyst 9. The anode 6 and the cathode 7 are closely attached to the surface of the proton exchange membrane 8 . The proton exchange membrane 8 is mainly composed of nafion, containing SO 3 H. Water molecules are decomposed into oxygen and hydrogen ions at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com