Stress test grid of nano material used for transmission electron microscopy

A nanomaterial and stress testing technology, applied in the analysis of materials, circuits, discharge tubes, etc., can solve the problems of high preparation requirements, inability to reveal the deformation mechanism of nanomaterials from the atomic scale, and inability to give changes in the microstructure, and achieve performance Reliable, simple structure, easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

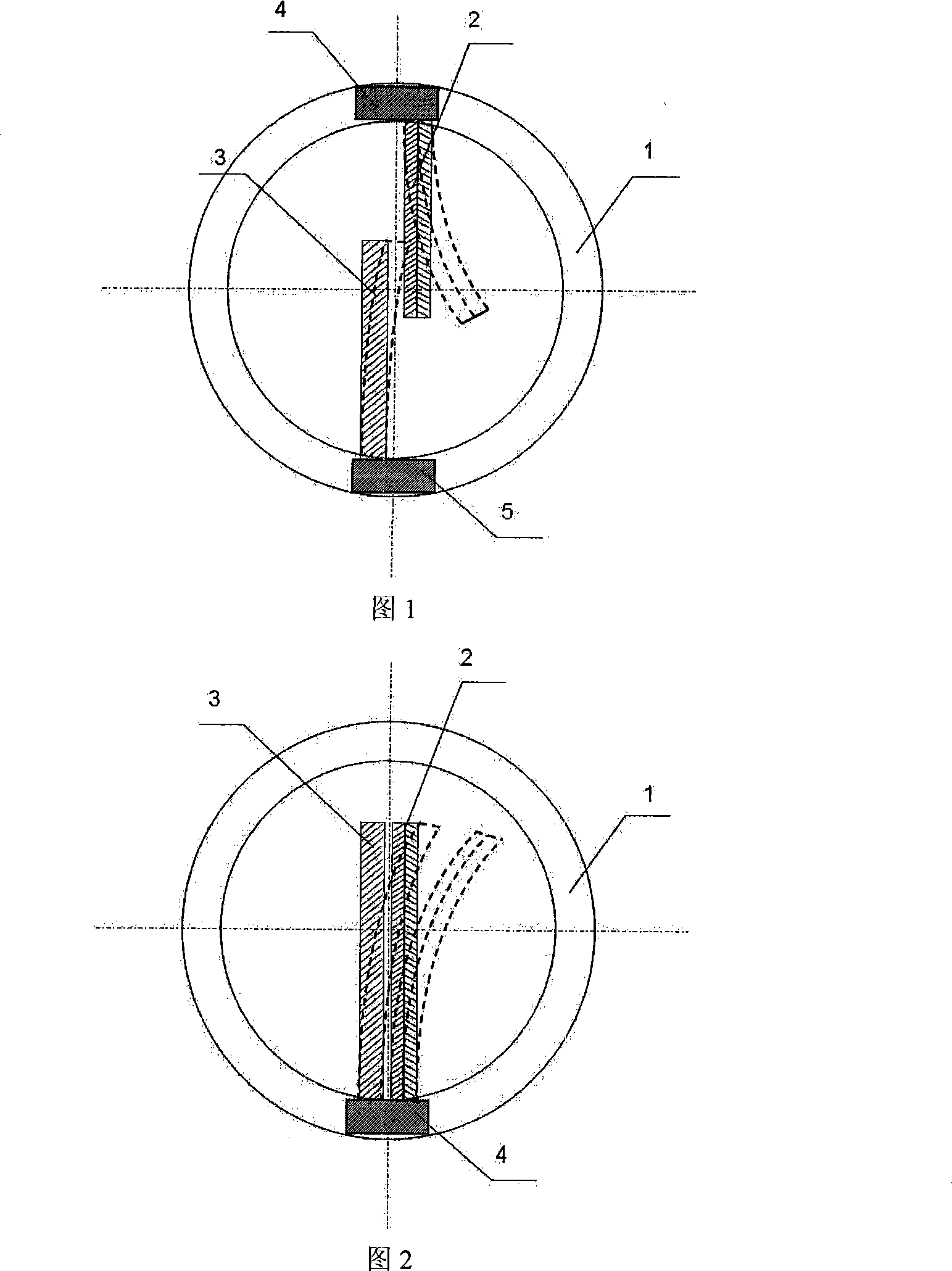

[0028] The carrying net includes a supporting part, a driving part and a mechanical testing part, the supporting part is a metal ring 1, and the driving part is a thermal bimetallic sheet 2 composed of different linear expansion coefficients and a metal sheet with a large linear expansion coefficient On the inner side, the metal sheet with a small coefficient of linear expansion is on the outside, and one end of the thermal bimetal sheet is fixed on the metal ring with a pressing piece 14, and the other end is a free end; On the other side, the cantilever beam 3, which is used to test the size of the force and has a known modulus of elasticity, is fixed on the metal ring using the compression piece II 5, and the slit width between the cantilever beam 3 and the thermal bimetal 2 is 2- 50 μm, distributed in the center of the metal ring 1 parallel to the thermal bimetal 2 and symmetrically.

[0029] The use steps of the present invention are as follows:

[0030]1. As shown in Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com