Method for measuring PH critical value of reinforcing steel corrosion

A technology of steel corrosion and determination method, which is applied in the direction of weather resistance/light resistance/corrosion resistance, measuring device, testing metal, etc., which can solve the problems of not being able to observe the corrosion behavior of steel bars at the same time, and unable to reflect the change information of local corrosion on the surface of steel bars in time. , to achieve the effect of strong practicability, simple equipment, high accuracy and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

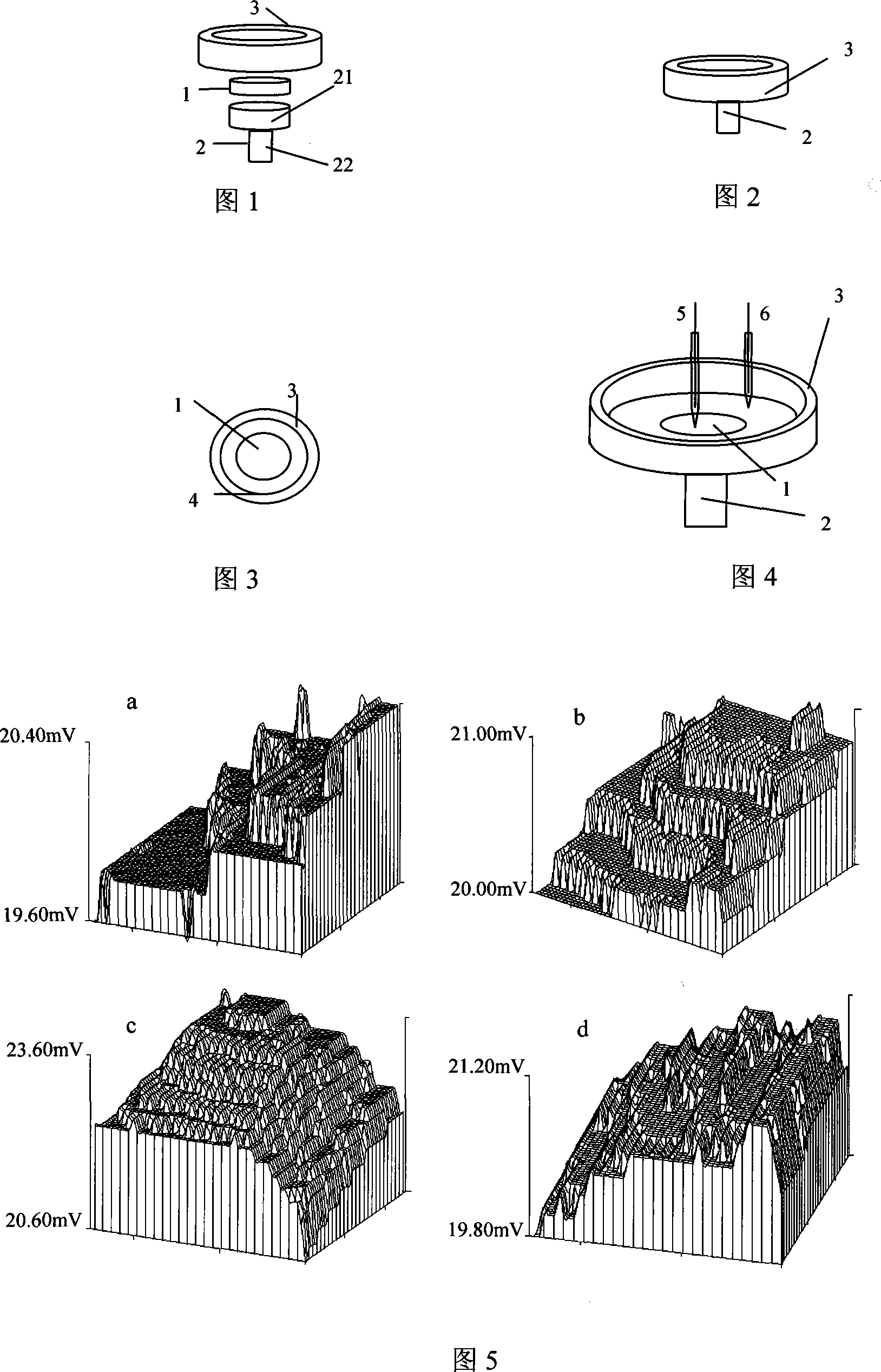

[0030] Figures 1 to 4 show the structural schematic diagrams of the reinforced electrode and the electrolytic cell of the embodiment of the present invention, and the process of preparing the reinforced electrode is given below. The steel bar electrode is provided with a steel bar test piece 1, a copper conductor 2 and a fixed ring 3, the steel bar test piece 1 is fixed in the fixed ring 3, the copper conductor 2 is connected to the back of the steel bar test piece 1, the steel bar test piece 1 is a flat cylinder, and the copper bar The conductor 2 is composed of two parts of cylinders 21 and 22 with different diameters, the upper part of the cylinder 21 of the copper conductor 2 is arranged in the fixed ring 3, and the fixed ring 3 is circular. The fixed ring 3 adopts organic glass insulating material. The size of the steel bar test piece 1 is 1.1 cm in diameter and 0.4 cm in thickness. The steel bar test piece 1, the upper cylinder 21 of the copper conductor 2 and the fixin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com