Multi-core cable detecting device and method thereof

A technology for multi-core cables and detection devices, applied in measurement devices, semiconductor/solid-state device testing/measurement, circuits, etc., can solve the problems of increasing the complexity and cost of detection devices, achieve simple structure, improve labor efficiency, and save labor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

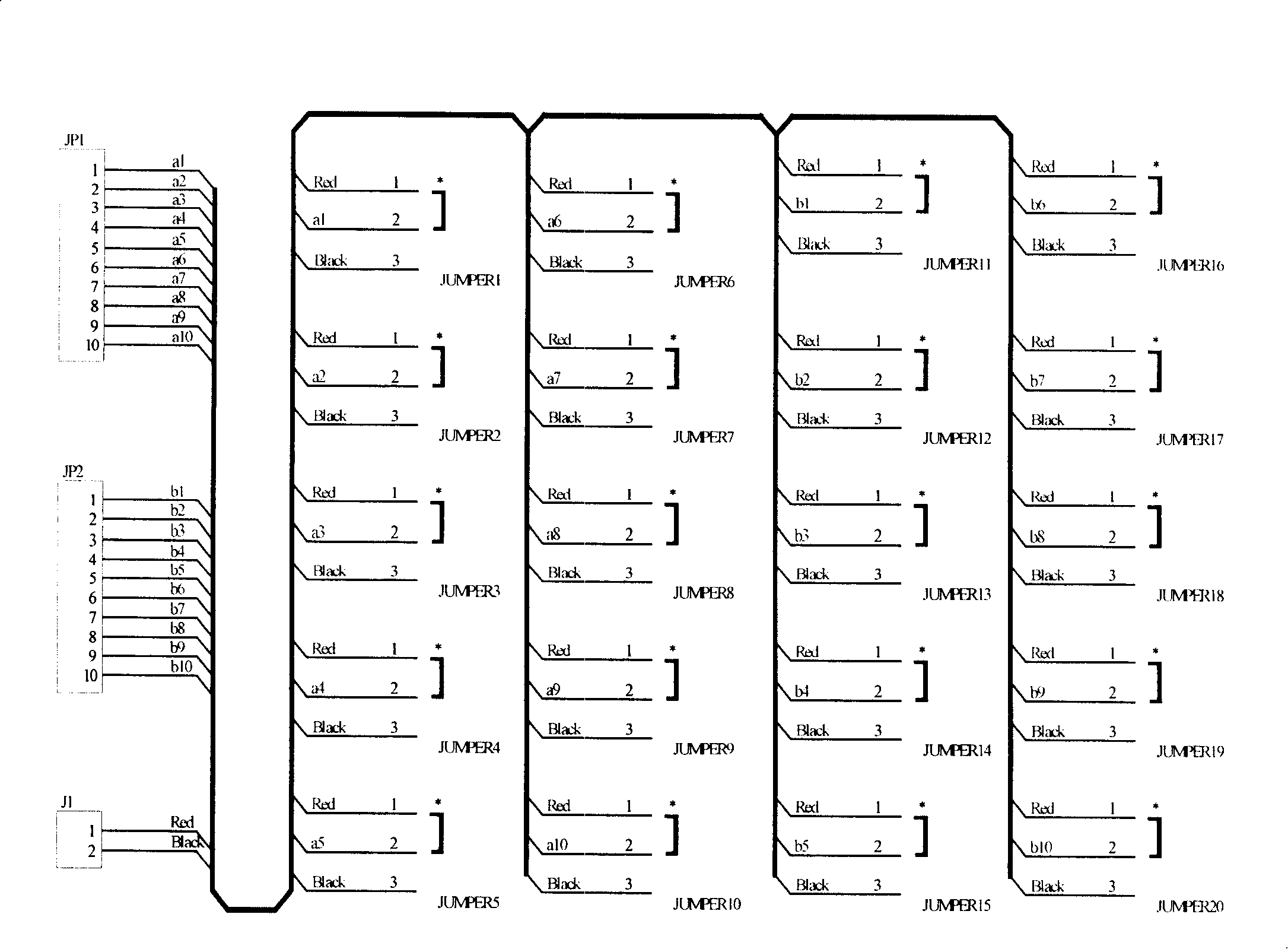

[0025] The multi-core cable detection device of the present invention, its preferred embodiment is as follows figure 1 As shown, it includes the front terminal JP1, the rear terminal JP2 and the test lead terminal J1.

[0026] The front connection terminal JP1 and the rear connection terminal JP2 respectively include a plurality of connection ports. It can include 10 to 20 wiring ports, or more, generally 10, 15, and 20 ports are preferred. In specific applications, it is best to correspond to the number of cores of the corresponding multi-core cable.

[0027] figure 1 The front connection terminal JP1 shown in includes 10 connection ports, which are the first to tenth front connection ports a1, a2, a3, a4, a5, a6, a7, a8, a9, a10; the rear connection terminal JP2 includes 10 The first to tenth rear wiring ports are respectively b1, b2, b3, b4, b5, b6, b7, b8, b9, b10. Up to 10-core cables can be tested. The structure of the plurality of connection ports can be made into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com